Buying cardboard displays isn't just about finding the lowest price; it's about securing a supply chain that won't collapse under retail pressure. A bad strategy leads to late launches and crushed boxes.

Packaging procurement is a strategic sourcing process where businesses acquire external resources, such as POP (Point of Purchase) displays and shipping materials, to support product distribution. This function manages the entire lifecycle from supplier identification and negotiation to quality control and final logistics compliance.

Many buyers think procurement is just sending a PO and waiting for a container. But in the high-stakes world of retail, real procurement is about managing risk, materials, and timelines before the ink even dries on the contract.

What is procurement in packaging?

Most brands treat packaging buying as an afterthought, but in retail, your display is the only salesperson on the floor. Ignored procurement details kill profit margins faster than bad creative.

Packaging procurement involves the systematic acquisition of packaging materials, including corrugated cardboard, rigid boxes, and flexible films, needed for product protection and marketing. This discipline focuses on balancing cost efficiency, structural integrity, and sustainability standards to ensure the SKU (Stock Keeping Unit) reaches the consumer intact.

The Strategic Anatomy of Sourcing Displays

Procurement in my industry is honestly a messy game of "Beat the Clock" combined with physics. I've seen clients from New York treat it like buying office supplies—they just want a box. But when you are dealing with Walmart's Greenlight program1 or Costco's structural requirements, procurement is really about risk management. The messy reality is that paper is a biological material. It reacts to the environment. I remember a disaster last year where a client sourced displays based purely on price from a generic trader. They didn't account for the "CNY Gap" (Chinese New Year). They placed the order in January, thinking they had time. They didn't. The factory shut down for 4 weeks, the lead time jumps from 15 days to 60 days, and they missed their Spring launch entirely. That's failed procurement.

Real procurement means understanding the "Invisible Costs" like volumetric weight. I often have to tell buyers that their design is 1 inch (2.54 cm) too wide for a standard 40HQ container. If we don't fix it, they ship 20% air, and ocean freight costs destroy their margin. Effective procurement isn't just buying; it's engineering the invoice. It's about demanding Value Engineering2. I often suggest merging two glued parts into one fold to save 30% on labor.

Furthermore, you must fight the "Material Spec" deception. Competitors often quote 20% lower by secretly downgrading to 35# Recycled Liner. It looks fine initially, but recycled fibers are short and break easily. The moment it hits the humid air in a New Orleans store, the "Bursting Strength" fails, and the display cracks. I have to explain that spending 5% more on High-Performance Virgin Kraft3 is the only way to prevent the display from looking "tired" after one week. If your procurement team isn't asking about ECT (Edge Crush Test)4 ratings—specifically 32 ECT versus 44 ECT—or discussing GMA Pallet dimensions of 48×40 inches (122×102 cm), they aren't procuring; they're gambling.

| Feature | Strategic Procurement | Transactional Buying |

|---|---|---|

| Focus | Total Cost of Ownership (TCO) | Unit Price Only |

| Timeline | "Backwards Planning" (60-Day Rule) | "ASAP" Panic Mode |

| Quality | ISTA 3A Drop Testing Standards | "Looks good enough" |

| Material | Specified Virgin Kraft Liner | Generic Recycled Testliner |

| Risk | 2% Free Spare Parts Policy | No Spares / High breakage |

It drives me crazy when buyers focus on saving five cents per unit but lose five thousand dollars in shipping damage. My approach is simple: I act as your technical gatekeeper, ensuring the specs meet the physical reality of a US supply chain before we cut a single sheet.

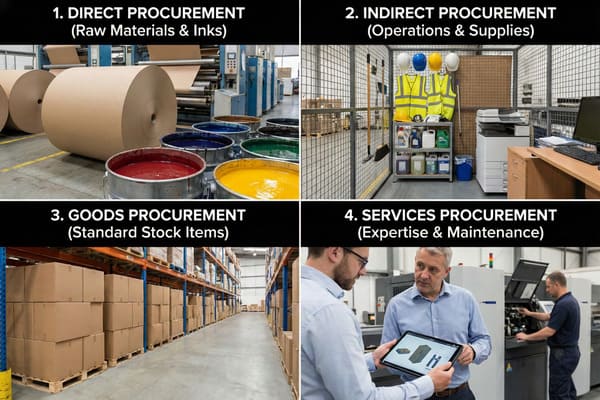

What are the 4 types of procurement?

You need to know which bucket your spending falls into, because sourcing a custom floor display requires a totally different protocol than buying standard shipping tape.

The 4 types of procurement are direct procurement, indirect procurement, services procurement, and goods procurement. Direct procurement involves raw materials for end products, while indirect covers operational supplies. Services procurement sources intangible skills like logistics, and goods procurement focuses on acquiring physical items and software tools for business use.

Navigating the Sourcing Matrix

In the world of Cardboard Displays, we live squarely in Direct Procurement, but it bleeds into Services when we handle Co-packing. Understanding this distinction matters because Direct Procurement requires strict quality control protocols that Indirect procurement doesn't. You can buy office paper (Indirect) from anywhere, but you can't buy a structural component from a random vendor without risking a collapse.

Let's talk about the "Ghost Factory" problem. In Direct Procurement, you need to know exactly who is making your product. I've had clients come to me after getting burned by a "Trading Company" (a form of Indirect sourcing where you don't see the factory). They thought they were buying direct, but when the color came out wrong—standard CMYK instead of the Pantone 877C Silver5 they needed—the middleman had no power to fix it. The result? A "Muddy Color" disappointment that ruined their brand image because the raw cardboard absorbed the metallic ink. We had to fix it by printing a white base layer first, something a trader wouldn't know.

For US buyers, Direct Procurement from China means you need to be "Audit-Ready." You can't just buy a display; you are buying the factory's compliance. Is the facility BSCI audited6? Do they understand Disney's FAMA requirements? If you are procuring "Services" like design, you need to ensure your IP is safe. I use a strict "IP & Privacy Fortress7" protocol with an NDA because I know Western brands are terrified of their designs being leaked to competitors. If your procurement strategy treats a custom POP display the same way you buy staplers (Indirect), you will end up with a pallet of unbranded, flimsy cardboard that collapses under the humidity of a Florida distribution center.

| Procurement Type | Application in Display Industry | Key Risk | My Factory Solution |

|---|---|---|---|

| Direct | Custom Floor & Pallet Displays | Material Fraud (Low ECT) | "Golden Sample" Protocol |

| Indirect | Warehouse Supplies / Tape | Cost Creep | Bulk Sourcing |

| Services | Co-packing & Graphic Design | IP Theft / Leaks | "Zero-Leak" Data Policy |

| Strategic | Long-term Seasonal Contracts | Supply Chain Gaps | "CNY Gap" Inventory Hold |

I treat every order as a strategic partnership, not a one-off purchase. Whether you need a full "Direct" manufacturing run or a "Service" based structural design consultation, I make sure the technical specs protect your bottom line.

What is a procurement package?

If you send a vague email asking for a quote, you will get a vague product. The procurement package is your technical bible that keeps the factory honest.

A procurement package is a comprehensive collection of documents and specifications sent to potential suppliers during the bidding process. It typically includes the RFQ (Request for Quotation), technical drawings, BOM (Bill of Materials), quality standards, and delivery timelines to ensure accurate pricing and manufacturing compliance.

The "Tech Pack" Reality Check

This is where 90% of projects fail. A client sends me a JPG image and says, "Make this." That is not a procurement package; that is a wish list. A real procurement package needs to define the physics of the box. Without it, you are asking for trouble.

I've had to have tough conversations with buyers who didn't specify the material grade. They got a quote from a competitor that was 20% cheaper. Why? Because the competitor switched the material from High-Performance Virgin Kraft8 to Recycled Testliner. It looked the same in the photo, but recycled fibers are short and weak. The moment it hit the humid air in a New Orleans store, the "Bursting Strength" failed, and the display cracked at the fold lines. A proper package must include the Dieline Template9 (which I often have to create for them because their designers don't know ArtiosCAD).

It needs to specify the Print Finish—are we doing standard matte or Anti-Scuff Matte to prevent fingerprints? It must define the Barcode Placement to avoid retailer chargebacks. Walmart requires the UCC-128 label on the long side, not just anywhere. If your package doesn't specify "Grain Direction" (vertical for strength), a lazy factory will print it horizontally to save paper, and your display will buckle. I refuse to quote until we build a "Zero-Frustration" spec sheet together. We even need to define the Overprint Attributes in the prepress stage to ensure no white gaps appear on the edges.

| Component | Why It Matters | The "Harvey" Standard |

|---|---|---|

| Material Spec | Prevents "Soggy Bottoms" | 44 ECT Virgin Kraft (No Recycled Liner) |

| Color Profile | Ensures Brand Consistency | G7 Master Calibration (Grayscale) |

| Structure File | Prevents Assembly Nightmares | Native ArtiosCAD 3D File |

| Testing Spec | Prevents Shipping Damage | ISTA 3A Drop Test Requirement |

I don't just accept your package; I audit it. If I see you asked for a "Hot Stamp" finish but you want to be "100% Recyclable," I'll stop you and suggest Cold Foil instead. I fix the mistakes in the paperwork so you don't pay for them in the warehouse.

What is the simple meaning of procurement?

Strip away the jargon, and procurement is just about connecting a need with a solution without losing money in the process.

The simple meaning of procurement is the strategic process of obtaining goods or services required for business operations. It encompasses identifying needs, sourcing reliable suppliers, negotiating terms, and ensuring the final delivery meets agreed quality and cost expectations, effectively connecting a demand with a supply solution.

It's About ROI, Not Just Buying

Simple doesn't mean easy. To me, the simple meaning of procurement is "Profit Protection." You aren't just buying cardboard; you are buying the Sales Lift10. A well-placed display increases sell-through by 400% compared to the shelf.

But here is the messy part: "Simple" procurement often ignores the "Instruction Manual" Reality Check. I've seen beautiful displays thrown in the trash by Walmart staff because the assembly instructions were a page of dense text. If the stock boy can't build it in 3 minutes, your procurement failed. So, I simplify the result. We use IKEA-style "No-Text" Visual Guides or print a QR code on the box that links to a video. We add a "Red Bag" with spare clips because we know things get lost.

We also have to manage the "Lithium Nightmare." Clients love flashing LEDs in headers to grab attention, but "Simple" procurement means handling the dangerous goods compliance. If you ship a display with lithium batteries as "General Cargo," US Customs will seize the container. I have to source Button Cell batteries with MSDS certification11 and ensure a "Pull-Tab" is installed to prevent fire risks. Furthermore, I handle the HS Code Optimization so you don't get hit with a surprise 25% tariff, and I verify the ISF 10+2 Filing so your container doesn't get stuck in Long Beach. Real procurement makes the complex mess of global manufacturing feel simple to you, ensuring the Safety Factor of 3.5 is met so nothing collapses on a child in the store.

| Aspect | The "Complicated" Way | The "Simple" (Smart) Way |

|---|---|---|

| Assembly | 10-page text manual | QR Code Video Link |

| Design | 20 glued parts | "Smart Simplification" (Folded structure) |

| Logistics | Guessing pallet fit | 48×40 GMA Optimized Footprint |

| Validation | Waiting 10 days for samples | 24-Hour "White Sample" Protocol |

My job is to make the manufacturing process boring for you. You shouldn't have to worry about glue chemistry or grain direction. You just need to know the display will arrive, stand up straight, and sell your product.

Conclusion

Procurement is the backbone of successful retail execution. It's the difference between a display that sells and one that swells. By focusing on technical specs, compliance, and strategic sourcing, you protect your brand.

Would you like me to create a Free Structural 3D Rendering or send you a Physical White Sample to test your product fit?

Explore this link to understand how Walmart's Greenlight program influences procurement strategies and risk management. ↩

Learn about Value Engineering to discover innovative ways to reduce costs while maintaining quality in procurement. ↩

This resource explains the benefits of using High-Performance Virgin Kraft for durability and performance in display sourcing. ↩

Understanding ECT ratings is crucial for ensuring the strength and reliability of packaging materials in procurement. ↩

Explore this link to understand the significance of Pantone colors in branding and printing, ensuring your designs stand out. ↩

Learn about BSCI audits to ensure your suppliers meet ethical and quality standards, protecting your brand's reputation. ↩

Discover how implementing an IP & Privacy Fortress can safeguard your designs and intellectual property from leaks. ↩

Explore the advantages of High-Performance Virgin Kraft for durable packaging solutions that ensure product integrity. ↩

Learn how to create effective Dieline Templates to streamline your packaging design process and avoid costly errors. ↩

Understanding Sales Lift can enhance your procurement strategy, ensuring better ROI and effective display placements. ↩

Exploring MSDS certification helps ensure compliance and safety in your procurement processes, especially with hazardous materials. ↩