I meet “die” every day on our shop floor. Many readers meet it only in product specs. Let me make it simple and useful.

A die is a precision tool or shape-forming device that cuts, forms, or stamps raw material into a defined geometry; in packaging and cardboard displays, a die usually means a steel-rule pattern that punches and creases board to make flat parts that fold into final structures.

I run a cardboard display factory. I see how one small die decision changes cost, lead time, and strength. Keep reading if you want clear choices and fewer surprises.

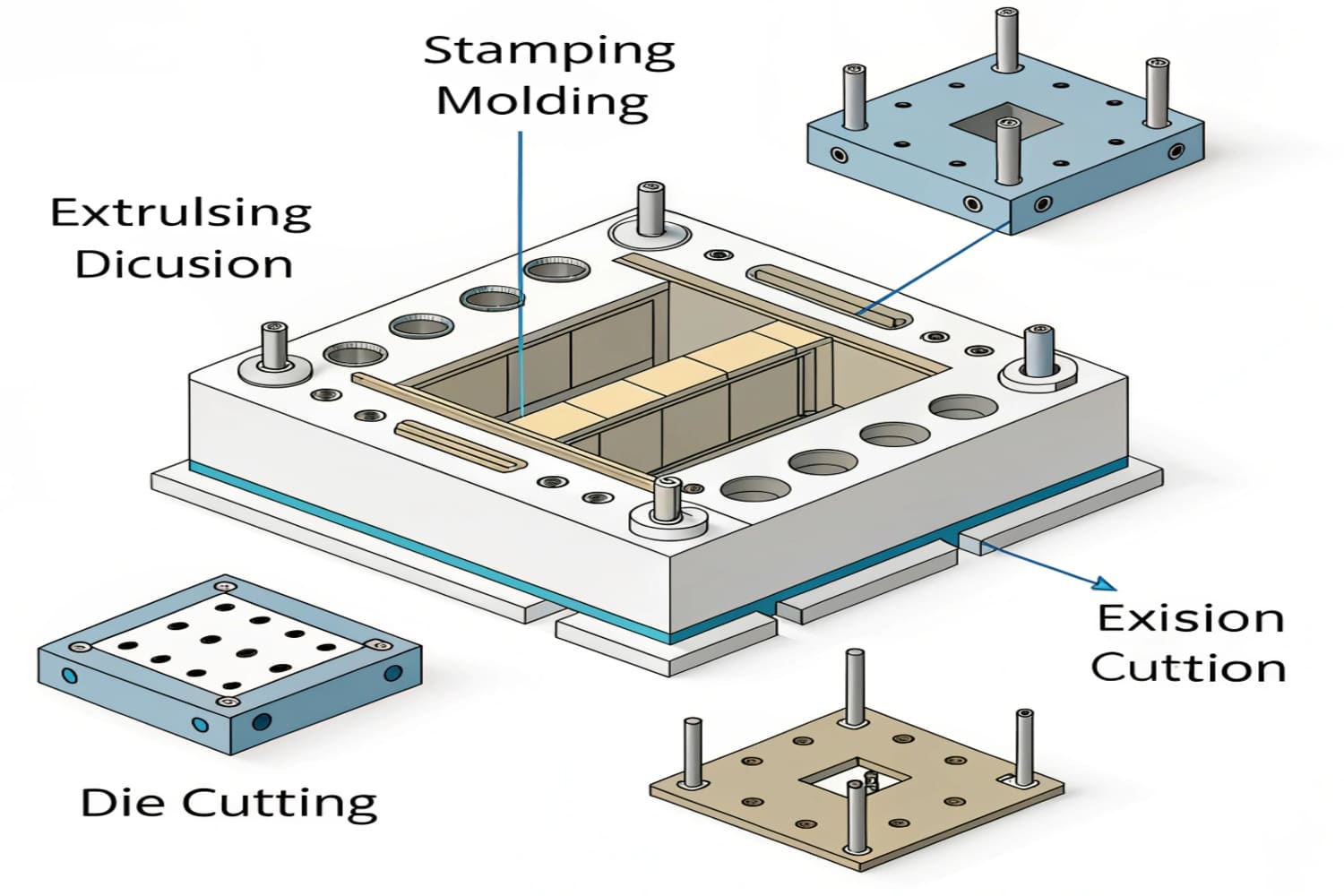

What is a die in manufacturing?

I started with metalworking textbooks. I later learned on the floor that real dies must survive operators, deadlines, and dust. The best definition is practical, not poetic.

In manufacturing, a die is a hard tool that shapes material by cutting, bending, drawing, embossing, or coining; it transfers a cavity or edge geometry to sheet, strip, or web using force from a press or converting machine.

Why this matters for displays

A cardboard display looks simple. It is not. The die defines every panel, tab, and lock. If my die is off by 0.5 mm, a shelf leans, a slot tears, or a load test fails. I use steel-rule dies1 for corrugated and paperboard, and I use rotary or flatbed formats depending on run size and board caliper. I keep rules at 23.8 mm height for E-flute and 23.5 mm for thicker board when I need cleaner nicks. I specify nicking patterns to hold pieces in the sheet for fast stripping. I set crease channel widths to match liner strength, so fold lines do not crack. When a client pushes a flash launch, I rely on digital knife tables2 for prototypes, then lock steel-rule after sign-off. A good die speeds make-ready. A great die reduces waste, improves color-to-cut register, and makes assembly easy for store staff.

| Die Type | Typical Use | Material | Pros | Cons |

|---|---|---|---|---|

| Steel-rule (flatbed) | Corrugated displays | SRK + plywood base | Fast build, low cost | Lower precision vs CNC milled |

| Rotary die | High volume, thin board | Paperboard web | High speed | Die cost higher |

| Progressive metal die | Metal parts | Steel | Tight tolerance | Not for paper |

| Digital knife | Prototyping | Any sheet | No tooling wait | Slow per piece |

Is a die a cube?

I hear this a lot from buyers who picture dice from a game. A die in factories rarely looks like that.

No. In manufacturing, a “die” is not a cube; it is a tool or pattern of any shape that forms or cuts material, often flat or ring-shaped, built for a specific process.

Scope, components, and tolerance3

A die is more than metal strips. The bill of materials matters. I specify rule height, bevel, hardness, and bend radii. I define crease matrix size to match board thickness and flute. I add make-ready notes for patching and underlay. I include registration holes for repeat orders, because our profit model depends on reorders with minimal change. I record the die number in our ERP so the same tool supports future variants. I also tag safe-edge zones for digital printing bleed. My team logs tolerance as ±0.3 mm for cut-to-print4 on flatbed runs and tighter on rotary. We test with transport simulation when displays hold heavy gear, like crossbows. We run ISTA-style stacking and vibration checks on samples. This avoids slumped shelves and color drift after shipping. When we say “send the die file,” we mean the 1:1 CAD with cut/crease layers, bridges, and grain. That file becomes the contract between design, die-maker, and press.

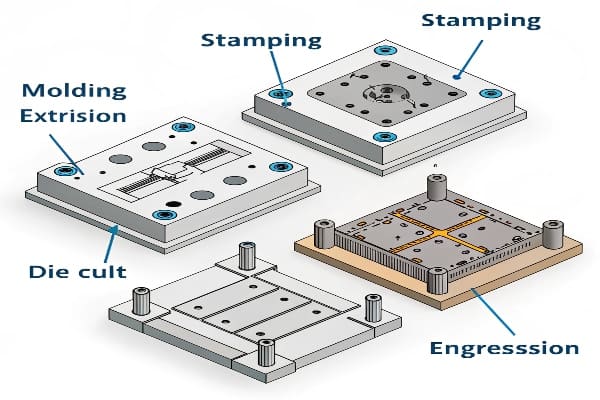

| Term | What it is | Looks like | Where I use it |

|---|---|---|---|

| Steel-rule die | Plywood board + rules | Flat panel | Corrugated POP |

| Rotary die | Cylindrical tool | Drum | High-speed paperboard |

| Embossing die | Matched metal set | Plates/blocks | Logos, textures |

| Punch & die set | Male/female pair | Rings, blocks | Holes, cutouts |

What is called a die?

Language changes with industry. I keep my team strict on terms, because terms become specs, and specs become invoices.

We call it a “die” when the tool has a defined cutting or forming profile that, under pressure, gives the workpiece a repeatable shape; in packaging, the die includes cutting rules, creasing rules, and ejector rubber.

Scope, components, and tolerance

A die is more than metal strips. The bill of materials matters. I specify rule height, bevel, hardness, and bend radii. I define crease matrix size to match board thickness and flute. I add make-ready notes for patching and underlay. I include registration holes for repeat orders, because our profit model depends on reorders with minimal change. I record the die number in our ERP so the same tool supports future variants. I also tag safe-edge zones for digital printing bleed. My team logs tolerance as ±0.3 mm for cut-to-print on flatbed runs and tighter on rotary. We test with transport simulation when displays hold heavy gear, like crossbows. We run ISTA-style stacking and vibration checks on samples. This avoids slumped shelves and color drift after shipping. When we say “send the die file,” we mean the 1:1 CAD with cut/crease layers, bridges, and grain. That file becomes the contract between design, die-maker, and press.

| Component | Function | Spec I check | Why it matters |

|---|---|---|---|

| Cutting rule | Separates parts | Height, bevel | Clean edge, less dust |

| Creasing rule | Creates fold lines | Width, matrix | Crack-free folds |

| Ejector rubber | Pushes waste | Durometer, layout | Fast stripping |

| Nicking | Holds parts in sheet | Count, spacing | Prevents fly-outs |

| Make-ready | Pressure tuning | Underlay map | Even cut/crease |

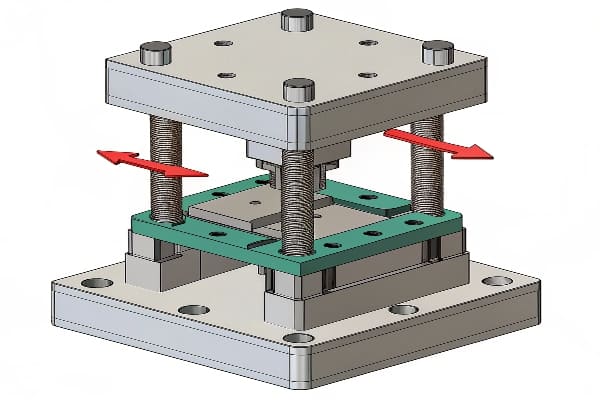

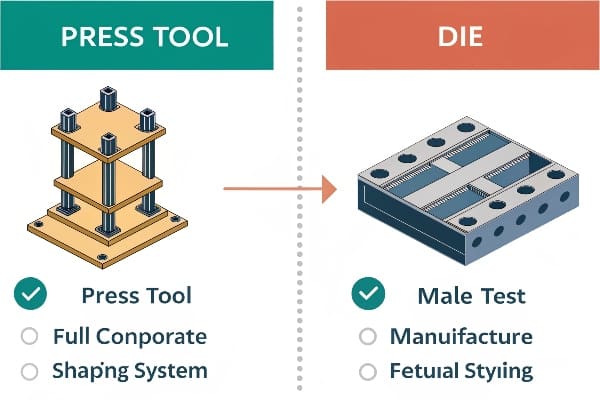

What is the difference between a press tool and a die?

People mix these words. I keep it simple for new buyers and engineers on their first packaging launch.

A die is the shaped tool that cuts or forms material; a press tool is the complete tooling setup in the press, which includes the die plus holders, plates, guides, and make-ready that apply the force.

System vs. part, and why buyers should care

A die is the profile. A press tool5 is the system that makes the profile work at speed. In cardboard converting, my die goes into a chase with clamps, bolts, and register blocks. The press tool includes the stripping frame, blanking set, pin units, and the make-ready sheets that tune pressure. When a client asks why two suppliers quote different prices, I often find one price includes only the die board6. The other includes the full press tooling and a blanking set for faster throughput. This explains serious lead-time gaps. I also look at consistency. A strong press tool cuts waste and reduces color-to-cut variation, which keeps reorders smooth. For a hunting brand with strict deadlines, I chose to invest in a full press tool, not just the die board. We cut make-ready time by half, met the launch window, and avoided overtime freight. That saved more money than the extra tooling cost.

| Aspect | Die | Press Tool |

|---|---|---|

| Definition | Profile that cuts/forms | Assembly that holds and actuates the die |

| Includes | Rules, matrix, rubber | Die, chase, plates, guides, frames |

| Cost | Lower | Higher |

| Lead time | Short | Longer |

| When I choose | Prototypes, small runs | Launches, repeat orders, high speed |

Conclusion

A die defines shape. A press tool delivers speed and repeatability. I use both to cut cost, hit dates, and keep displays strong.

Explore the benefits of steel-rule dies to understand how they enhance efficiency and precision in cardboard display production. ↩

Learn how digital knife tables streamline the prototyping process, reducing wait times and increasing flexibility in design. ↩

Understanding tolerance is crucial for ensuring precision in die cutting, which directly impacts product quality and production efficiency. ↩

Exploring the concept of cut-to-print will enhance your knowledge of flatbed runs and their significance in achieving accurate and high-quality outputs. ↩

Understanding press tools is crucial for optimizing production efficiency and reducing costs in manufacturing. ↩

Exploring die boards helps buyers make informed decisions about tooling options and their impact on production. ↩