Choosing the wrong finish ruins your brand image faster than a typo. Scratches, fading, and "muddy" colors turn premium products into discount items instantly, so getting this right is non-negotiable.

The best coatings for corrugated packaging include UV (Ultraviolet) High-Gloss for visual vibrancy, Aqueous Coating for eco-friendly protection, and PP (Polypropylene) Lamination for maximum durability. These finishes provide essential resistance against scuffing and moisture while enhancing the retail presentation.

There is a massive difference between a coating that looks good on a PDF and one that survives a Walmart aisle. Let's break down the chemistry and the costs.

What are the different types of packaging coatings?

Most buyers think "Shiny means good," but that's a rookie mistake. Lighting, touch, and shipping durability dictate your choice, not just aesthetics.

The different types of packaging coatings include Aqueous Coating (AQ) for quick-drying protection, UV Coating (Ultraviolet) for high-gloss visual appeal, Varnish for budget-friendly sealing, and PP Lamination (Polypropylene) for superior tear resistance and structural durability.

The Structural Anatomy of Surface Finishes

I learned this the hard way. A few years ago, a client wanted a "Midnight Black" luxury cosmetic display. We used a standard matte laminate. By the time the store employees finished stocking the shelves, the black surface was covered in white scratches and oily fingerprints. It looked trashy. That's when I switched to Anti-Scuff Matte PP Lamination1. You can literally drag a coin across it, and it won't leave a mark. It costs about 15% more, but it saves the brand's reputation.

We also have to distinguish between "Inline" and "Offline" processes. Standard varnishes and Aqueous coatings are applied "Inline" on the printing press (like a Heidelberg Speedmaster). It's fast and cheap because it happens while the ink is still drying. However, Lamination is an "Offline" process. We have to take the printed paper, move it to a separate laminating machine, and thermally bond a plastic film to it. This adds 2-3 days to production but creates a physical plastic shield.

For high-volume retail like Costco, we have to talk about moisture. Standard varnish does nothing against a wet mop. That is why I apply a "Mop Guard2" — a heavy-duty, water-resistant coating specifically to the bottom 4 inches (10 cm) of any floor display. Without this, the cardboard wicks up dirty floor water, and the base turns into mush within a week.

Another massive issue is the "Washboard Effect." If you print high-gloss UV directly onto standard B-flute cardboard, the waves of the corrugation show through the reflection. It looks cheap. To fix this, I force a switch to E-Flute3 (Micro-flute) or use a "Litho-Lam" process where we print on a smooth clay-coated sheet first, then glue it to the corrugated. And if you are looking for that velvet feel without the plastic waste, I'm now using Soft Touch Aqueous Coating4. It mimics the feel of soft-touch plastic but remains curbside recyclable.

Lastly, be careful with "Slip." High-Gloss UV is incredibly slippery. If you stack boxes with UV coating on a pallet, they slide off like ice blocks during trucking. I often have to add a "Non-Skid" additive or use "Slip Sheets" between layers to prevent the whole pallet from toppling over in the container.

| Coating Type | Cost Index | Scratch Resistance | Process | Recyclability |

|---|---|---|---|---|

| Aqueous (AQ) | Low ($) | Medium | Inline (Fast) | High (Repulpable) |

| UV High Gloss | Medium ($$) | High | Inline (Fast) | Medium (Chemicals) |

| Standard PP Laminate | High ($$$) | High | Offline (Slow) | Low (Plastic Film) |

| Anti-Scuff Matte Lam | Premium ($$$$) | Extreme | Offline (Slow) | Low (Plastic Film) |

| Soft Touch Aqueous | Medium ($$) | Low | Inline (Fast) | High (Repulpable) |

I always tell clients to spend the extra nickel for anti-scuff film on dark prints. It saves me from reprinting 500 units when store staff abuse them during setup.

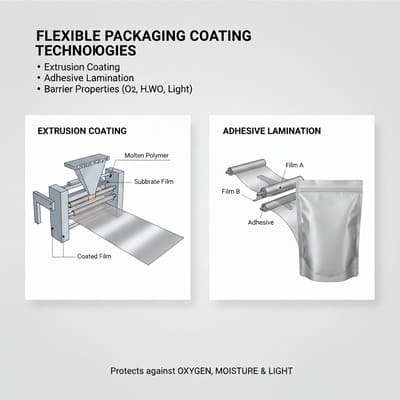

What are the coating technology for flexible packaging?

"Flexible" doesn't just mean plastic bags; it means cardboard that bends without snapping. Cracking ink at the fold line is a nightmare that makes new displays look old.

Coating technologies for flexible packaging utilize elastomeric polymers and water-based varnishes designed to stretch with the substrate. These specialized finishes prevent ink cracking at fold lines (score lines) by maintaining elasticity during the die-cutting and assembly processes.

The Physics of "Score Cracking" and Elasticity

Here is a scenario that drives me crazy: A client approves a proof in humid Shenzhen, but the display ships to a dry distribution center in Las Vegas. The humidity drops, the paper fibers shrink, and pop—the ink cracks right at the fold line, exposing the white paper underneath. We call this "Litho-Cracking," and it usually happens on dark colors or heavy ink coverage.

To fight this, standard coatings aren't enough because they are brittle. When the board folds 180 degrees, a hard UV coating will shatter like glass because it cannot stretch. I now use a specialized "Anti-Crack" Film Lamination or a water-based varnish with high elasticity agents. These coatings act like a rubber band; they stretch with the paper tension instead of breaking. This is particularly vital for "Header Cards" which are often folded tightly during shipping.

Also, we have to talk about the new "PFAS-Free" mandate. Many traditional water-resistant coatings (the ones that make paper cups hold coffee) contain "forever chemicals." With states like California and New York banning these, I've had to overhaul our supply chain to use Verified PFAS-Free water-based coatings5. This is critical for any food/snack display. If you ignore this, you aren't just looking at a bad display; you're looking at a lawsuit.

Another aspect of flexibility is the "Spot UV" registration. Designers love putting shiny Spot UV over logos. But cardboard absorbs moisture and expands/contracts. If we use a rigid plate, the varnish "drifts" off the logo. I use a high-viscosity screen printing method with a 0.5mm "Trapping" allowance. This allows the coating to flex slightly in position, covering the logo perfectly even if the board shifts during the print run.

For metallic finishes, I use Cold Foil6 instead of Hot Stamping on flexible areas. Hot stamping stamps a rigid foil onto the board, which cracks instantly if you fold it. Cold foil is applied as a "wet" process inline with the ink, allowing it to remain flexible. It's the only way to get a gold border on a fold line without it looking like broken glitter.

| Feature | Standard UV Coating | Elastic "Anti-Crack" Varnish | PFAS-Free Barrier Coating | Cold Foil |

|---|---|---|---|---|

| Flexibility | Brittle (Cracks) | High (Stretches) | Medium | High |

| Climate Tolerance | Poor in Dry Heat | Excellent | Good | Good |

| Regulatory Status | Standard | Standard | Mandatory (Food) | Standard |

| Visual Finish | High Gloss | Satin/Matte | Invisible | Metallic |

It is heartbreaking to see a beautiful display ruined by a white crack on the header. I use specific elastic varnishes now for any order going to dry climates like Arizona.

What property does corrugated cardboard have that makes it useful for packaging?

It's not just "paper." It's an engineered sandwich that defies gravity—if you respect the physics of the grain.

The properties of corrugated cardboard that make it useful include its fluted architecture for vertical crush resistance, long-fiber tensile strength for tear prevention, and air-cushioning capabilities that protect products during transit and stacking.

The Engineering of Flute Profiles and Load Bearing

Designers treat cardboard like it's a solid block of wood. It isn't. It has a "grain" (the direction of the flutes). I once saw a competitor's display collapse in a Target store because their designer rotated the grain horizontally on a load-bearing wall to save 5% on scrap paper. The wall buckled immediately.

We rely on ECT (Edge Crush Test)7 ratings to measure this. For a standard floor display, I won't touch anything less than 32 ECT. If it's a pallet display for Costco, we bump that up to 44 ECT or even 48 ECT BC-Flute (Double Wall). This "Double Wall" (mixing B-flute and C-flute) creates a plywood-like strength. Why? Because humidity kills cardboard. In a humid Florida warehouse, cardboard loses 30-40% of its strength. I use a "Safety Factor of 3.58"—meaning if your product weighs 100 lbs (45 kg), I build the display to hold 350 lbs (158 kg).

We also have to distinguish between ECT and BCT (Box Compression Test). ECT measures the raw board strength, but BCT measures the finished box. A box can fail BCT even with high ECT board if the "Flute Pitch9" (number of flutes per foot) is wrong. Tighter flutes (like E-flute) resist crushing flat, while larger flutes (C-flute) offer better vertical stacking strength but are softer.

Another trick is the "Double-Wall Header." Humidity makes single-sheet headers curl like a potato chip. By folding the cardboard over itself to create a double wall, the tension keeps the header rigid and straight. And for shelf visibility, we use the "Chin-Up" angle. By slanting the shelf 15 degrees, we exploit the material's stiffness to present the product directly to the shopper's eye level, not their knees.

Lastly, impact cushioning. The air trapped inside the flutes acts like a microscopic airbag. When a forklift driver drops a pallet, the flutes crush slightly, absorbing the kinetic energy before it hits your glass bottles. Solid plastic or wood doesn't do that; they transfer the shock directly to the product.

| Specification | Flute Height | Flutes Per Foot | Application | Weight Capacity (Est) |

|---|---|---|---|---|

| 32 ECT B-Flute | 1/8" (3mm) | 47 +/- 3 | Floor Displays | 30 lbs (13 kg) / shelf |

| 44 ECT C-Flute | 3/16" (4mm) | 39 +/- 3 | Shipping Cartons | 50 lbs (22 kg) / shelf |

| 48 ECT BC-Flute | 1/4" (6mm) | Combined | Pallet Displays | 2500 lbs (1133 kg) |

| E-Flute | 1/16" (1.5mm) | 90 +/- 4 | Counter Units | Light Cosmetic |

I don't just guess the strength. If you tell me it's for Costco, I automatically upgrade to EB-flute because I know their forklifts take no prisoners.

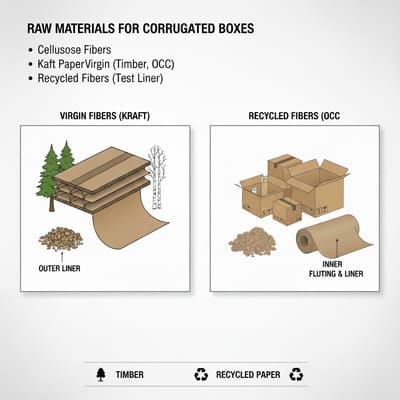

What is the raw material for corrugated boxes?

You think it's just wood pulp? Wrong. The specific mix of virgin vs. recycled soup determines if your box survives the trip.

The raw material for corrugated boxes consists primarily of Kraft linerboard (derived from pine wood pulp) and semi-chemical fluting medium. This combination provides superior tensile strength and moisture resistance compared to recycled Testliner, which utilizes shorter fibers.

Virgin Kraft10 vs. Recycled Testliner: The Cost of Cheap Paper

Here is the dirty secret of the industry: Competitors quote you a price that is 20% lower by swapping Virgin Kraft for Recycled Testliner on the outer layers. It looks the same in the sample room. But recycled fibers are short—they have been chopped up too many times. They lack tensile strength.

When you ship that "cheap" display, the vibration in the truck causes the recycled paper to burst at the corners. For any structural component, I specify High-Grade Virgin Kraft Liner11. The long pine fibers act like rebar in concrete. They resist moisture better, which is crucial for the "Soggy Bottom" effect I mentioned earlier. Recycled paper acts like a sponge; in a humid shipping container, it absorbs water and collapses. Virgin kraft has natural resins that repel moisture.

We also have to talk about "Odor." It sounds weird, but 100% recycled Chinese cardboard sometimes smells like old socks when you open a sealed container that has been baking in the sun for 30 days. This is a disaster for clothing or food brands. Virgin Kraft is odorless. For sensitive clients, I mandate "Odor-Free12" material sourcing.

For the printed surface, we don't print on the brown kraft (unless you want that rustic look, but be warned: silver ink turns grey on brown paper). We use CCNB (Clay Coated News Back). It's a recycled sheet with a white clay coating on top for printing. It's cheaper than SBS (Solid Bleached Sulfate)13, which is pure white through and through. However, if you look closely at cheap CCNB, you might see tiny "speckles" or impurities in the clay. For ultra-premium brands (like Apple or Sephora), I switch to SBS or a high-grade "White Top Kraft" to ensure the white is pure and the colors pop without any background noise.

| Material Grade | Fiber Source | Cost | Moisture Resistance | Smell Risk |

|---|---|---|---|---|

| Virgin Kraft | Pine Pulp | High | Excellent | None |

| Testliner | Recycled Mix | Low | Poor | Medium |

| CCNB | Recycled + Clay | Medium | Medium | Low |

| SBS | Bleached Pulp | Premium | Good | None |

I refuse to use recycled testliner for the outer wall of a pallet display. It saves pennies but costs thousands when the bottom layer crushes under weight.

Conclusion

The coating isn't just a shiny finish; it's the armor that protects your brand from humidity, friction, and dirt. Whether you need Free Structural 3D Rendering to visualize the light reflection or a Physical White Sample to test the durability yourself, getting the specs right early saves you a fortune later. Get a Free Quote from us, and I'll ensure your packaging handles the real world, not just the showroom.

Explore the advantages of Anti-Scuff Matte PP Lamination for luxury displays and how it protects against scratches and fingerprints. ↩

Learn about Mop Guard coating and how it protects displays from moisture damage in high-volume retail environments. ↩

Discover the benefits of E-Flute in packaging, including its impact on print quality and structural integrity. ↩

Find out how Soft Touch Aqueous Coating mimics soft-touch plastic while being curbside recyclable. ↩

Learn about PFAS-Free coatings to ensure compliance with regulations and protect your brand from legal issues. ↩

Find out how Cold Foil printing can provide flexibility and stunning finishes for your projects. ↩

Understanding ECT is crucial for ensuring the strength and durability of cardboard displays. ↩

Exploring this concept helps in grasping how safety margins are calculated in load-bearing designs. ↩

Discover the importance of Flute Pitch in optimizing the performance of cardboard boxes and displays. ↩

Explore the advantages of Virgin Kraft, including its strength and moisture resistance, crucial for quality packaging. ↩

Learn why High-Grade Virgin Kraft Liner is essential for durability and moisture resistance in packaging. ↩

Discover the importance of Odor-Free materials, especially for sensitive products like food and clothing. ↩

Find out why SBS is favored for ultra-premium brands and how it enhances product presentation. ↩