Retail shelves are crowded, and your packaging blends in. You need a way to make your brand pop without breaking the bank or complicating the design process.

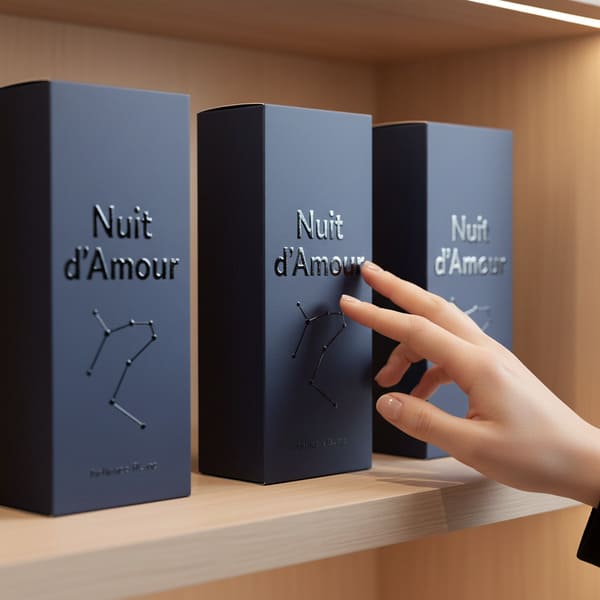

Spot UV printing applies a glossy, clear polymer coating to specific areas of a design rather than the whole surface. This technique creates a striking contrast between matte and shiny textures, instantly drawing the eye to logos or key details while adding a premium tactile feel to cardboard displays.

Many brands struggle to find the right finish that balances cost and impact, so let's look at how this technique changes the game.

What is the difference between UV and spot UV?

Many clients get confused by coating terminology. Choosing the wrong one can result in a shiny mess rather than a sophisticated look.

UV coating covers the entire printed surface with a protective gloss or matte layer, offering overall durability. In contrast, spot UV is applied only to specific areas, like a logo or text, to create a deliberate visual contrast and texture difference against the background.

The Mechanics of Flood vs. Targeted Coating

When we talk about standard "UV" in the printing industry, we are usually referring to flood UV coating1. This is a very common finish used in mass production for cardboard displays. The process involves flooding the entire printed sheet with a liquid varnish that is instantly cured using ultraviolet light. The main purpose of flood UV is protection. It seals the ink and prevents the corrugated board from scratching, scuffing, or fading during the long shipping process from China to the US. It gives the whole box a uniform sheen, which is functional but can sometimes look generic.

Spot UV2 is a completely different approach because it is a design element rather than just a protective shield. Instead of coating the whole sheet, we use a specific screen or plate to apply the varnish only to the areas you want to highlight. This requires high precision. If the registration is off by even a millimeter, the gloss will not align with your printed logo, and the effect will be ruined. Spot UV works best when applied over a matte lamination. The contrast between the non-reflective matte background and the high-gloss spot UV is what creates the visual "pop." Without that matte base, the spot UV gets lost. While flood UV is cheaper because it runs fast and covers everything, spot UV adds significant value by creating depth and a premium feel that standard gloss cannot achieve.

| Feature | Flood UV (Standard) | Spot UV |

|---|---|---|

| Coverage Area3 | 100% of the surface | Specific, targeted areas only |

| Primary Purpose4 | Protection and durability | Aesthetic contrast and branding |

| Base Requirement | Can go directly on paper | Best over Matte Lamination |

| Cost Impact | Low (Standard inclusion) | Moderate (Requires extra plate/setup) |

| Visual Effect | Uniform Gloss or Matte | High Contrast (Shiny vs. Dull) |

I always tell my clients that Spot UV is useless without a matte background to support it. At PopDisplay, my team checks your artwork files manually to ensure the registration marks align perfectly. We use precision equipment to make sure the gloss lands exactly on your logo, not two millimeters to the left, ensuring your brand looks flawless.

What is the use of spot UV?

A great design on a computer screen often looks flat when printed. You risk losing consumer attention if the physical box feels cheap.

Spot UV is used to create visual hierarchy and tactile engagement on packaging. By highlighting specific elements like brand names or product features, it guides the consumer's eye directly to the selling points. It also adds a luxury feel that encourages customers to touch the display.

Strategic Visual Hierarchy and Branding

The primary use of spot UV5 is to direct consumer attention. In a retail environment like Walmart or a specialized hunting shop, a customer scans shelves very quickly. This is often called the "three-second rule." You have three seconds to grab their attention. If your packaging is flat and one-dimensional, the eye slides right past it. Spot UV breaks that visual monotony. By adding a high-gloss finish to your main logo or a key product image, you catch the overhead store lighting. That reflection acts like a beacon. It tells the customer's brain that this specific part of the box is important.

Beyond just visuals, spot UV is used to create a tactile experience. Retail psychology tells us that if a customer picks up a product, the likelihood of purchase increases significantly. When a customer runs their hand over a cardboard display and feels the smooth, raised texture of the spot UV against the soft touch of a matte background, it signals quality. It makes the product feel expensive. This is why you see it used heavily in electronics and high-end cosmetics. For outdoor gear, it can be used to highlight the rugged texture of a product image or the sharp lines of a crossbow. It is not just decoration; it is a tool to increase the perceived value of the item inside the box. However, it must be used sparingly. If you spot UV everything, you highlight nothing. The goal is to create focus, not clutter.

| Benefit | Description | Impact on Sales |

|---|---|---|

| Visual Contrast6 | Separates elements from the background | High (Grabs attention) |

| Tactile Feel | Adds a smooth texture change | Medium (Encourages handling) |

| Perceived Value7 | Looks like a premium product | High (Justifies price) |

| Durability | Resists fingerprints on dark colors | Medium (Keeps display clean) |

I see many designs that try to spot UV everything, which creates a mess and defeats the purpose. My design team helps you select just the key focal points to highlight. We run test prints to ensure the varnish does not bleed into small text, guaranteeing that your Barnett Outdoors logo looks sharp and professional.

What is the difference between spot UV and raised UV?

You might want a 3D effect but do not know which technique to ask for. Using the wrong term can lead to disappointing results.

Spot UV applies a thin, flat layer of gloss that sits flush with the paper surface for a sleek look. Raised UV, also known as high-build UV, applies a much thicker layer of polymer, creating a noticeable three-dimensional texture that you can clearly feel with your fingertips.

Dimensionality and Tactile Impact

The difference here really comes down to the height of the varnish and the method of application. Traditional spot UV8 is relatively flat. It might have a thickness of around 10 to 20 microns. You can see it, and you can feel a change in friction, but it does not have a "bump." It is sleek and subtle. Raised UV9, often referred to as High-Build UV or sometimes by the brand name Scodix, is much thicker. We can build this up to 50 or even 100 microns high. This creates a true 3D effect that mimics embossing. You can run your finger over it and feel a distinct ridge. It is very impressive visually because it looks wet and heavy.

However, there is a trade-off in durability and physics. Cardboard displays are meant to hold weight and often flex during shipping or assembly. Raised UV relies on a thick layer of cured polymer. If the cardboard bends too much, that thick layer can crack or peel off because it is not as flexible as the paper beneath it. Traditional spot UV is thinner and moves better with the fiber of the paper. For a rigid setup box that sits on a shelf, raised UV is fantastic. But for a large floor display that needs to be folded and assembled by store staff, raised UV can be risky on fold lines. It also costs more because it consumes significantly more varnish and requires slower curing times to ensure the thick layer hardens completely without bubbling.

| Characteristic | Traditional Spot UV10 | Raised UV (High Build)11 |

|---|---|---|

| Thickness | 10-20 Microns (Flat) | 50-100 Microns (3D) |

| Tactile Effect | Smooth change | Distinct ridge/bump |

| Flexibility | High (Good for folding) | Low (Prone to cracking) |

| Cost | Moderate | High |

| Best Application | Logos, text, patterns | Water droplets, bold textures |

I often advise against heavy raised UV on structural fold lines because it will almost certainly crack during assembly. My factory performs bending tests on all coated samples. If you want that 3D look, I will adjust the structure to keep those areas flat so the coating stays intact during shipping.

What is the difference between spot UV and blind UV?

Subtlety can be a powerful design tool, but it is easy to miss the mark. Understanding these nuances helps you create a sophisticated background.

Spot UV places a glossy coating directly over a printed image or text to enhance its color and visibility. Blind UV applies the same glossy coating over a solid dark background or unprinted area, creating a "ghosted" or watermark effect that is only visible when light hits it at an angle.

Subtlety vs. Direct Enhancement

"Blind" in the printing world means there is no ink printed in the shape of the effect. When we do standard Spot UV, we are usually registering the gloss on top of a printed logo. For example, we print a red Barnett logo and then put gloss on top of that red ink to make it shine. Blind UV12 is different. We take a solid black or solid dark blue background, and we apply the clear gloss in the shape of a pattern or text, but there is no specific ink color underneath that shape. It is essentially gloss-on-matte.

The result is a very sophisticated, "ghosted" look. It is not visible from every angle. You have to tilt the box to see the pattern reveal itself. This is excellent for adding texture without making the design look busy. Imagine a hunting display with a solid black header. We could use Blind UV to put a camouflage pattern or animal tracks on that black background. It would look solid black from a distance, but as the customer walks by, the light hits the gloss, and the pattern appears. This conveys a high level of luxury and attention to detail. From a production standpoint, Blind UV is slightly easier regarding registration because we do not have to match an ink edge perfectly, but cleanliness is critical. Any dust trapped under the Blind UV becomes very visible because the background is usually uniform.

| Feature | Spot UV (Registered)13 | Blind UV14 |

|---|---|---|

| Underlying Layer | Printed Ink/Image | Solid Color or Unprinted |

| Visibility | High Contrast, always visible | Subtle, angle-dependent |

| Design Intent | Highlight specific info | Add texture/background depth |

| Registration Needs | Critical (Must match print) | Less Critical |

| Vibe | Bold, Shouty | Stealth, Premium |

I love using blind UV for background textures because it adds depth without distracting from the main product. My production line uses dust-free drying tunnels to ensure the blind coating remains crystal clear. We can create a subtle, high-end look for your packaging that competitors cannot easily copy.

Conclusion

Spot UV transforms standard cardboard into premium retail fixtures. It drives sales through contrast and touch. Contact me to start your custom sample today.

Explore this link to understand how flood UV coating enhances protection and aesthetics in printed materials. ↩

Discover the unique benefits of Spot UV and how it adds value and depth to printed designs. ↩

Understanding the coverage area helps in choosing the right UV coating for your project. ↩

Exploring the primary purposes can guide you in selecting the best UV coating for your specific needs. ↩

Explore this link to understand how spot UV enhances packaging and attracts consumer attention effectively. ↩

Understanding visual contrast can enhance your product's appeal and effectiveness in attracting customers. ↩

Exploring perceived value can help you justify pricing strategies and improve sales. ↩

Learn about Traditional spot UV's characteristics and how it differs from Raised UV, helping you make informed printing choices. ↩

Explore the advantages of Raised UV printing to understand its unique visual and tactile effects, enhancing your design projects. ↩

Learn about Traditional Spot UV printing to understand its applications and benefits for enhancing visual appeal. ↩

Explore the advantages of Raised UV printing for creating stunning textures and effects in your designs. ↩

Explore this link to understand how Blind UV printing enhances design sophistication and luxury in packaging. ↩

Explore this link to understand how Spot UV enhances print quality and design impact. ↩

Discover the subtle elegance of Blind UV printing and how it adds depth to your designs. ↩