Choosing the right finish for your custom POP displays matters. It impacts durability, color vibrancy, and how customers perceive your brand in retail environments like Walmart or local pro shops.

Lamination protects your cardboard displays and enhances visual appeal. The right choice depends on your lighting environment, budget, and desired aesthetic. Glossy offers high vibrancy and protection, while matte provides a sophisticated, non-reflective finish ideal for bright retail spaces and premium branding.

Let's break down the options so you can pick the perfect finish for your next retail campaign.

How do I know if brow lamination is right for me?

Don't let the terminology confuse you. When we talk about lamination for your retail displays, we are basically asking if your cardboard stands need extra protection and a specific style upgrade.

Lamination is right for you if your displays face high traffic, moisture, or long shelf lives. If you need your colors to pop or require a premium feel to match high-end products like crossbows, adding a laminate film is essential for structural integrity and aesthetics.

The Structural and Aesthetic Impact of Film Lamination

When determining if lamination1 is necessary for your corrugated displays, you must look beyond just the visual aspect and consider the physical environment of the retail store. A raw cardboard display, printed directly without a protective film, is susceptible to moisture, dust, and abrasion. In North American retail environments, floor displays often encounter cleaning equipment and wet mops. Without lamination, the bottom of your display can soak up water, causing the structural integrity2 of the B-flute or EB-flute corrugated board to fail. This leads to the dreaded "leaning tower" effect, where displays collapse under the weight of heavy products like hunting gear or beverages.

From a technical standpoint, lamination adds a layer of polypropylene (PP) or polyethylene (PE) film over the printed paper sheet before it is mounted to the corrugated board. This film acts as a tension barrier. When we crease and fold the cardboard to build your stand, raw paper often cracks at the fold lines, revealing the white paper fiber underneath. Lamination prevents this cracking, keeping the graphics seamless. For high-ticket items, perception is reality. If the display looks cheap and damaged, the customer assumes the product is also low quality. If you are shipping displays fully assembled (pre-packed) across the country, lamination also provides essential scuff resistance against the vibrations of the truck, ensuring the branding arrives pristine.

| Feature | Non-Laminated (Varnish Only) | Film Laminated (Gloss/Matte) |

|---|---|---|

| Moisture Resistance3 | Low (Absorbs water easily) | High (Water-resistant barrier) |

| Fold Line Quality | Prone to ink cracking | Smooth, no white cracks |

| Scuff Resistance4 | Low | High |

| Cost | Lower | Moderate to High |

| Recommended Use | Short-term (2 weeks), Bin Displays | Long-term (3+ months), Floor Displays |

I always advise clients like you to laminate floor displays. It prevents the "mop water" damage at the bottom. My factory uses eco-friendly glues so you don't fail compliance checks, ensuring your hunting gear looks rugged yet premium on the shelf.

Which lamination is better, glossy or matte?

This is the most common question I get from brands. The answer comes down to your specific store lighting, your artwork design, and the brand image you want to project.

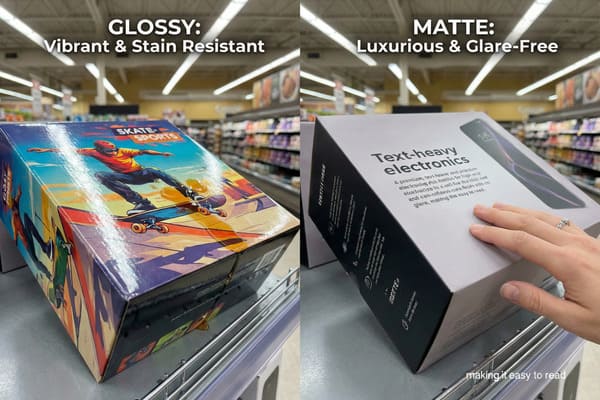

Glossy lamination makes colors vibrant and resists stains, making it great for action-oriented brands. Matte lamination absorbs light, eliminates glare, and offers a luxurious texture, which is often preferred for high-ticket items or text-heavy designs under harsh supermarket lighting.

Analyzing Visual Performance in Retail Environments

Choosing between glossy and matte is not just about personal preference; it is a strategic decision based on retail physics5. Glossy lamination is the industry workhorse. It enhances color saturation, making blacks deeper and reds more intense. It reflects light, which catches the eye from a distance. However, this reflection is a double-edged sword. In stores with aggressive overhead fluorescent lighting, like Costco or intense sporting goods aisles, glossy displays can suffer from severe glare. If the glare hits the text area, the customer cannot read your key selling points or scan your QR code.

Matte lamination6, on the other hand, diffuses light. It creates a "soft" look that screams luxury and sophistication. For technical products where reading specifications on the box is crucial, matte is superior because it remains legible from any angle. However, matte can slightly desaturate colors, making them look a bit more muted compared to the digital file. There is also a tactile difference. Matte feels smooth and expensive, while gloss feels like plastic. We also have to consider the "scratch factor." Glossy tends to show micro-scratches from handling more than matte does, but matte can sometimes show oily fingerprints if not treated with a specialized scuff-resistant coating. When we print your high-resolution hunting imagery, a glossy finish7 might make the scene look like a photo, while a matte finish might make it look like a high-end art print.

| Characteristic | Glossy Lamination | Matte Lamination |

|---|---|---|

| Light Interaction8 | Reflects light (High Glare) | Absorbs light (No Glare) |

| Color Impact | Increases contrast and saturation | Slightly softens/mutes colors |

| Readability9 | Can be difficult under bright lights | Excellent readability |

| Tactile Feel | Smooth, slick | Velvety, soft |

| Fingerprint Visibility | Visible | Less visible (if scuff-resistant) |

I find that for outdoor brands, matte often signals higher quality. However, if your artwork has deep blacks and bright reds, glossy might be better. We can send you a physical proof of both from my Shenzhen facility so you can see the difference under your own office lights.

Who is not a good candidate for brow lamination?

Sometimes, adding a standard plastic lamination film isn't the best fit for your project, especially regarding sustainability goals or budget constraints.

Brands with strict plastic-free mandates or extremely tight budgets may not be good candidates for traditional plastic film lamination. If you require 100% curbside recyclability without separation, water-based varnish or aqueous coatings are better alternatives that offer moderate protection without the use of plastic films.

Sustainable Alternatives and Budget Considerations

While film lamination offers the best physical protection, it introduces a layer of plastic (usually PP) to the paper. While this is accepted in many recycling streams, strict "plastic-free" mandates from certain European or eco-conscious North American retailers might flag it. If your brand story relies heavily on 100% biodegradability, you might not be a candidate for film lamination. In this case, we look at Aqueous (AQ) Varnish10 or UV coatings11. These are liquid coatings applied during the printing process. They dry to form a protective shell.

They are significantly cheaper than film lamination because they skip a production step (the laminating machine). However, they do not offer the same structural reinforcement. A varnish-coated display is more likely to crack at fold lines and has lower moisture resistance. If your product is lightweight and the display is a "one-and-done" promotion (like a Quick Display or PDQ) that only needs to last two weeks, film lamination is overkill. You are paying for durability you do not need. But for heavy items like compound bows or large floor stands that must endure three months of shopping carts hitting them, skipping lamination is a risk. We have to balance your "Green" goals with the reality of supply chain survival.

| Factor | Film Lamination | AQ / UV Varnish |

|---|---|---|

| Material Composition | Paper + Plastic Film | Liquid Coating (Plastic-free options) |

| Recyclability | Requires separation in some regions | 100% Curbside Recyclable12 |

| Durability13 | High (Structural support) | Low to Medium (Surface only) |

| Cost Efficiency | Higher Cost | Lower Cost |

| Best Application | Heavy items, Long-term use | Short promos, Light items |

I know you care about cost and quality. If you are running a short two-week promo, skip the expensive lamination and let me use a high-gloss varnish. It saves you money and keeps the environmentalists happy, while still giving your boxes a decent shine.

Does eyebrow lamination look good on everyone?

In the world of packaging, "everyone" means every design style. We need to ensure the finish matches your specific artwork to avoid visual disasters.

Lamination looks good on almost every display, but the specific type must align with your graphic design. Busy, high-contrast artwork benefits from gloss to enhance details, while minimalist, pastel, or text-heavy designs look significantly better with matte finishes to ensure readability and elegance.

Matching Graphic Design to Surface Treatments

The interaction between ink, paper, and lamination is complex. Not every design looks good with every finish. For example, if your design uses large areas of solid black or dark blue, glossy lamination14 will highlight every minor imperfection in the cardboard surface beneath. The "fluting" (the wavy inner layer of the cardboard) might show through as faint lines, disrupting the solid color. Matte lamination hides these surface imperfections much better, creating a flat, uniform appearance.

On the flip side, if your design involves metallic effects or high-contrast photography (like a hunter in the woods at dawn), matte lamination15 might flatten the image too much, making it look dull or muddy. Gloss helps separate the foreground from the background. We also need to consider gradients. Sometimes, a heavy matte laminate can cause "banding" in subtle gradients if the print quality isn't calibrated perfectly. For your specific industry, camouflage patterns are unique. Realism is key. A high-gloss camo pattern looks artificial because leaves and bark aren't naturally shiny. A matte finish on camouflage mimics the natural texture of the woods, making the imagery more authentic to your customer base. It creates an emotional connection that "plastic-looking" gloss destroys.

| Design Element | Recommended Finish | Why? |

|---|---|---|

| Large Solid Dark Colors16 | Matte | Hides substrate texture and imperfections. |

| High Contrast Photos17 | Glossy | Increases depth and vibrancy. |

| Text-Heavy Info | Matte | Improves readability by reducing glare. |

| Camouflage / Natural | Matte | Mimics natural textures, increases realism. |

| Neon / Bright Pop | Glossy | Maximizes the impact of bright inks. |

I have seen great designs ruined by the wrong finish. For your hunting gear, I suggest a matte finish to prevent glare on the camouflage patterns. My design team checks every file before production to ensure the lamination won't distort your brand colors.

Conclusion

Selecting the right lamination balances protection, style, and budget. Whether you choose glossy for vibrancy or matte for elegance, the right finish ensures your displays succeed in the retail jungle.

Explore the advantages of lamination to enhance the durability and aesthetics of your retail displays. ↩

Learn how lamination can maintain the structural integrity of displays, preventing damage and ensuring longevity. ↩

Understanding moisture resistance can help you choose the right materials for durability and longevity. ↩

Exploring scuff resistance will guide you in selecting materials that maintain their appearance over time. ↩

Understanding retail physics can help you optimize your product displays for better customer engagement and sales. ↩

Explore the advantages of matte lamination to understand its impact on print quality and aesthetics. ↩

Learn how a glossy finish can enhance or detract from the visual appeal of your printed materials. ↩

Understanding light interaction helps in choosing the right lamination for your project. ↩

Explore how different lamination types can enhance or hinder readability in printed materials. ↩

Explore the advantages of Aqueous Varnish for eco-friendly printing solutions and cost savings. ↩

Learn how UV coatings can improve the longevity and quality of your printed materials. ↩

Understanding curbside recyclability can help you make eco-friendly choices and improve your recycling habits. ↩

Exploring durability factors can guide you in selecting the right finish for your projects, ensuring longevity and quality. ↩

Discover how glossy lamination can elevate your designs and learn about its effects on color and texture. ↩

Explore the advantages of matte lamination to enhance your designs and understand its impact on visual quality. ↩

Explore how matte finishes can enhance the appearance of dark colors by hiding imperfections. ↩

Discover how glossy finishes can elevate the vibrancy and depth of high contrast images. ↩