I need display boxes fast. Retail buyers want samples, and my launch date is close. I want clean prints, strong board, and fair prices. I pick dependable sources now.

Buy display boxes from B2B cardboard display manufacturers for custom work, local packaging suppliers for quick stock sizes, big craft chains for small runs, and online marketplaces for variety; confirm MOQ, lead time, certifications, proofs, and shipping before you pay.

I buy most custom units direct from factories in Shenzhen, because I get structure design, 3D renderings, free modifications, strength tests, and tight timelines under one roof. Demand grows, and sustainability matters more. Floor POP units still lead growth. I plan supply with these trends in mind.

What are display boxes called?

Many people use different names. I hear buyers ask for PDQ, SRP, CDUs, trays, dump bins, floor stands, and endcap units. The core idea stays the same. The box holds, presents, and sells products.

Display boxes are often called PDQ displays, SRP (shelf-ready packaging), CDUs (counter display units), countertop displays, floor displays, dump bins, trays, pallet displays, or endcap stands, depending on size, placement, and function.

Terms, uses, and materials

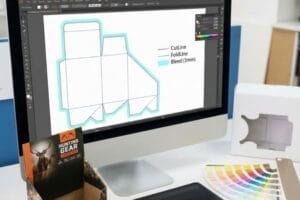

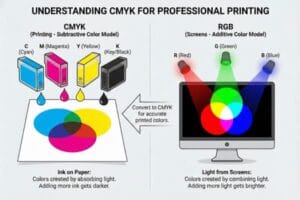

I match terms to the retail spot first, then to structure. This keeps briefs clear and quotes clean. When I talk with buyers, I show a simple map of names to placements and materials. That avoids rework and protects the schedule. It also helps my team choose the right flute, coating, and print method. In fast launches, I like digital print1 for short runs and quick changes. In big runs, I switch to flexo or offset2. I keep die lines simple, so assembly is easy on the store floor. I avoid rare terms in spec sheets. This reduces confusion between design, quoting, and production.

| Term (Common) | Placement | Typical Material | When I Use It |

|---|---|---|---|

| PDQ / CDU | Counter or checkout | Paperboard or E/B-flute | Impulse buys and small packs |

| SRP (Shelf-Ready3) | Existing shelf | Corrugated tray + perforated cover | Fast replenishment and tidy facings |

| Floor Display4 | Aisle or promotional zone | Double-wall corrugated | New launch, high visibility |

| Dump Bin | Open top floor unit | Heavy corrugated | Bulk or mixed SKUs |

| Pallet Display | Warehouse club floor | Pallet + corrugated shroud | Warehouse clubs and quick setup |

| Endcap Standee | Gondola end | Corrugated + header | Seasonal or hero SKU push |

What is another name for a display box?

My customers use simple words. They say tray, shipper, carton display, pop-up stand, or retail display. The best name is the one your team shares and understands.

Another name for a display box is PDQ, SRP, CDU, countertop display, tray display, shipper display, retail display, or POP display; the preferred term changes by region and by retailer.

Regional wording and briefing tips

I work with teams in the United States, Canada, the United Kingdom, and Australia. They use different words for the same idea. I keep a short glossary in every brief. I add a mockup and a 3D rendering, so no one relies only on words. I also list payload, target dwell time, and planogram slot. Clear language saves weeks. In one launch, I cut three revision loops just by switching “CDU5” to “PDQ counter tray6” on the spec. The printer picked the right board on the first try. Color stayed consistent, and the ship date held. Consistency beats clever language.

| Region | Common Name | Notes |

|---|---|---|

| United States | PDQ, Countertop Display7, Shipper | “PDQ” = Pretty Darn Quick, fast to set |

| United Kingdom | CDU, SRP, FSDU (Free-Standing Display Unit8) | “FSDU” equals floor display |

| Australia | CDU, SRP, Shipper | Similar to UK usage |

| Canada | PDQ, Counter Unit, Tray Display | Bilingual artwork is common |

I also plan for market growth9. Asia-Pacific capacity helps with speed and price. North America stays stable and mature. Europe asks for greener inks and coatings10. I align terms and specs with each region’s habits to avoid delays.

What’s the difference between a shadow box and a display case?

People mix these two. A shadow box is a deep frame. A display case is a full enclosure. The choice depends on size, security, and handling.

A shadow box is a deep frame with a backing for wall mounting; a display case is a fully enclosed cabinet or box, often glass or acrylic, for 360-degree viewing and better protection.

Use cases, protection, and retail fit

I use shadow boxes11 for light, flat items like medals, small tools, and sample kits. They are easy to hang behind a cash desk. They do not block sound or dust well. I use display cases12 when the product is premium, breakable, or regulated. They lock. They support lighting. They allow full views. For heavy gear, like a crossbow, I often pair a cardboard floor display with a small locking acrylic case on a shelf for the hero unit. The floor unit holds inventory. The case shows the feature piece and keeps hands safe. I write the choice into the brief, with weight limits and store rules. This prevents store-level rejections.

| Feature | Shadow Box13 | Display Case14 |

|---|---|---|

| Protection | Low to moderate | High (dust, touch, theft) |

| Viewing | Front only | Multi-side or 360-degree |

| Material | Wood, MDF, paperboard window | Glass or acrylic, metal frames |

| Mounting | Wall | Counter, floor, wall, pedestal |

| Best For | Awards, samples, flat sets | Premium SKUs, fragile items |

| Cost | Lower | Higher |

What is a glass display case called?

Buyers use a few names. Shops say glass showcase or glass cabinet. Museums say vitrine. The word does not matter. Fit, safety, and lighting matter more.

A glass display case is commonly called a glass showcase or vitrine; other names include glass cabinet, museum case, retail glass case, and glass counter display.

Types, materials, and buying checklist

I choose the term “glass showcase15” when I brief retail projects. I list tempered glass16, lock type, hinge type, shelf load, and cable routing for lights. I decide early if I need glass or if optically clear acrylic is better. Acrylic weighs less and ships safer. Glass resists scratching and feels premium. For roadshows, I use knock-down acrylic cases on a corrugated pedestal. For permanent stores, I buy framed glass vitrines with leveling feet. I add a cardboard backer or header panel above to deliver brand story without heavy hardware. This hybrid saves cost and speeds rollout in chains like warehouse clubs.

| Type | Best For | Pros | Cons |

|---|---|---|---|

| Glass Showcase (Framed)17 | Permanent retail | Premium feel, secure, durable | Heavy, higher cost |

| Vitrine (Museum-grade) | Galleries, luxury | Conservation glass, sealed | Very high cost, long lead |

| Glass Counter Case | Point-of-sale | Built-in storage, easy access | Limited height for tall items |

| Acrylic Case (Knock-down)18 | Roadshows, pop-ups | Light, ships flat, fast setup | Scratches easier, lower security |

Before I place an order, I verify certifications. I ask for FSC19 on board, RoHS/REACH20 on inks, and lab test data on load. I get color targets and a press proof. I run a transport test. I do this because I lost a peak season once. A shipment arrived with weak inserts and crushed corners. Now I never skip the checklist. My factory team runs load tests, drop tests, and fits trays to the master carton. I keep changes free until the sample is right. This protects repeat orders, which drive my margins.

Conclusion

You can buy display boxes from factories, local suppliers, craft chains, or marketplaces. Pick the right term, confirm specs, and test samples. Clear briefs and simple language keep launches on time.

Explore the benefits of digital print for packaging, especially for short runs and quick changes, to enhance your production efficiency. ↩

Learn when to choose flexo or offset printing for large runs, ensuring optimal quality and cost-effectiveness in your projects. ↩

Explore the advantages of Shelf-Ready packaging to enhance your product visibility and streamline restocking. ↩

Learn design tips for Floor Displays that attract customers and boost sales in retail environments. ↩

Understanding the term CDU can help clarify product specifications and improve communication across teams. ↩

Exploring the concept of a PDQ counter tray can enhance your knowledge of retail displays and improve your project outcomes. ↩

Explore this link to understand the significance of Countertop Displays in enhancing product visibility and sales. ↩

Discover the advantages of Free-Standing Display Units in retail settings to maximize space and attract customers. ↩

Exploring this resource will provide insights into effective strategies for market growth tailored to various regions. ↩

This link will help you understand the environmental advantages and innovations in greener inks and coatings. ↩

Explore this link to understand how shadow boxes can enhance your display strategy and protect your items effectively. ↩

Discover the advantages of display cases in showcasing premium items and ensuring their safety. ↩

Learn how to craft a Shadow Box to beautifully display your cherished memories and collectibles. ↩

Explore the advantages of Display Cases for showcasing valuable items securely and attractively. ↩

Explore this link to understand how glass showcases enhance product visibility and security in retail environments. ↩

Learn about tempered glass’s durability and safety features, making it ideal for retail displays. ↩

Explore this link to understand how a Glass Showcase can enhance your retail space with its premium feel and durability. ↩

Discover why an Acrylic Case is ideal for roadshows, offering lightweight design and easy setup for your display needs. ↩

Understanding FSC certification can help ensure sustainable practices in your supply chain, enhancing your brand’s credibility. ↩

Exploring RoHS and REACH regulations will inform you about compliance and safety standards, crucial for your product’s marketability. ↩