Are you worried that a cheap display might collapse under your product's weight? Choosing the right material is the only way to prevent in-store disasters and protect your brand image.

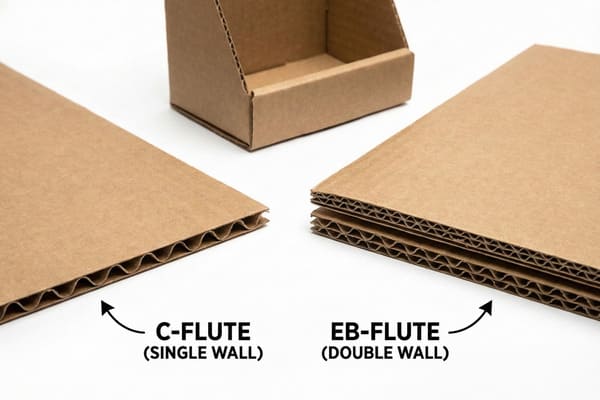

We use high-strength corrugated fiberboard, reinforced with fluted sheets and sturdy liners. Depending on the load, we select specific grades like B-flute for standard items or double-wall EB-flute for heavy merchandise, ensuring durability and sustainability.

Understanding the specific composition of these materials helps you make better decisions for your retail strategy. It ensures your products arrive safely and look professional.

What materials are used in making board displays?

Many brands face the nightmare of displays that buckle before the promotion even starts. The secret to longevity lies in selecting the correct board grade for your specific weight requirements.

Corrugated fiberboard is the primary material, consisting of a wavy fluted layer sandwiched between flat linerboards. Common grades include single-wall (C-flute) for standard weight and double-wall (EB-flute) for heavy-duty items like beverages or tools.

The Structural Anatomy of Corrugated Strength

The strength of your display comes down to the engineering of the corrugated board1. It is not just a single piece of thick paper. It is a sandwich structure. You have two flat outer layers called liners and a wavy middle layer called the medium or flute. The arch shape of the flute is what gives the board its ability to resist bending and crushing pressure.

For heavy products, like hunting gear or large beverage bottles, a standard single wall board is often not enough. We see many failures where factories use a generic C-flute for heavy loads. This leads to the display leaning or collapsing after a few days in a humid store. To fix this, we often recommend a double-wall structure2, such as EB-flute. This combines two layers of fluting to create a dense, rigid wall that acts almost like wood.

Another critical factor is the paper grade used for the liners. There is "Test Liner," which contains more recycled content, and "Kraft Liner3," which is made from virgin pulp. Kraft liner is much stronger and more resistant to moisture. Since many of our clients ship goods across the ocean from China to the US, moisture resistance is vital. A display made with high-quality Kraft liner will not turn soft when it hits a humid warehouse in Florida. We also have to consider retailer compliance. Big chains like Costco have strict Edge Crush Test (ECT) standards4. If the material does not pass these lab tests, your product might get rejected at the distribution center.

| Flute Profile | Thickness (Approx.) | Stacking Strength | Print Surface Quality | Best Use Case |

|---|---|---|---|---|

| E-Flute5 | 1.6 mm | Low | Excellent | Counter displays, small boxes |

| B-Flute6 | 3.2 mm | Medium | Good | Standard floor displays |

| C-Flute | 4.0 mm | Medium-High | Fair | Shipping cartons, simple displays |

| EB-Flute7 | 4.8 mm | Very High | Good | Heavy products, pallet displays |

| BC-Flute | 7.0 mm | Extremely High | Fair | Industrial parts, bulk bins |

I ensure we test every batch of material before production starts. My team conducts load-bearing tests in our factory to guarantee the structure holds your specific product weight without buckling.

What are display boxes made of?

If your packaging looks dull or tears easily, customers will walk right past it. The material of the display box must balance visual appeal with the toughness needed for retail environments.

Display boxes utilize lightweight yet rigid paperboard or micro-flute corrugated board such as E-flute or F-flute. These materials offer a smooth surface for high-quality lithographic or digital printing while providing sufficient structural integrity for countertop placement.

Balancing Print Quality with Structural Integrity

When we talk about display boxes, specifically PDQ (Pretty Darn Quick) trays or countertop units, the surface material is just as important as the core. The most common material we use for the "skin" of the display is CCNB8, which stands for Clay Coated News Back. This is a type of recycled board that has a white clay coating on one side. This coating creates a smooth, bright surface that allows for high-resolution printing.

However, print quality often suffers if the underlying corrugated board is too rough. If the flutes are too large, you get a "washboard" effect where the lines of the corrugation show through the print. This looks cheap and ruins the branding. To solve this, we use micro-flutes like E-flute or even F-flute. These have very tight waves, providing a flat surface that makes the artwork pop.

For clients who are very strict about brand colors, like my customers in the outdoor industry, material consistency is key. Different batches of paper absorbs ink differently. A logo printed on a recycled liner looks duller than on a virgin white liner. We also use lamination9. This is a thin plastic film (glossy or matte) applied over the printed paper. It protects the ink from scratching during transport and adds a premium feel. Lamination also adds a layer of water resistance. If a customer spills coffee on the counter next to your display box, the liquid won't immediately soak in and ruin the unit.

| Material Type | Surface Characteristics10 | Cost Level | Print Vibrancy11 |

|---|---|---|---|

| CCNB (Clay Coated) | Smooth, white, coated | Low-Medium | High |

| SBS (Solid Bleached) | Premium white, very smooth | High | Very High |

| Kraft (Natural) | Brown, fibrous, uncoated | Low | Low (Rustic look) |

| K-Fold (White Top) | White, uncoated, matte | Medium | Medium |

We solve color inconsistency by providing physical proofs before mass production. I have my team run a full digital sample so you can check the color accuracy on the actual material we intend to use.

What are display materials?

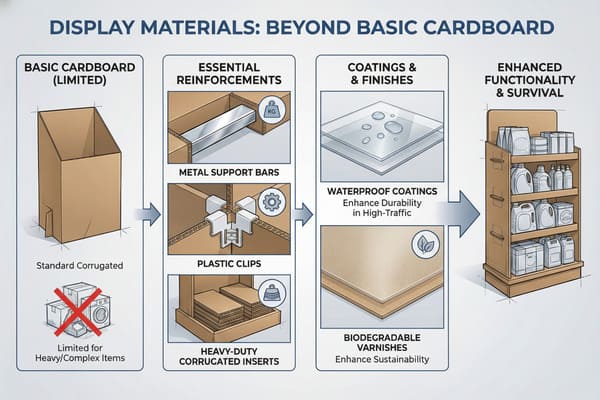

Using only paper for heavy or complex items can limit your design options. Sometimes, additional components are required to enhance functionality and ensure the display survives the retail floor.

Beyond basic cardboard, display materials include essential reinforcements like metal support bars, plastic clips, and heavy-duty corrugated inserts. Waterproof coatings and biodegradable varnishes are also applied to enhance durability and sustainability in high-traffic retail environments.

Reinforcements and Eco-Friendly Additions

A cardboard display is often more than just paper. When we design for heavy items, like power tools, bottled drinks, or hunting equipment, cardboard alone might sag over time. In these cases, we integrate other materials into the design invisible to the shopper. Metal bars are the most common reinforcement. We place these metal tubes under the shelves. They transfer the weight to the vertical walls of the display, allowing a paper shelf to hold 50 pounds or more without bending.

Plastic components were standard for years, such as shelf clips or hooks for hanging blister packs. However, the industry is shifting. Many of my clients now ask for 100% plastic-free displays12 to meet sustainability goals. We are replacing plastic clips with clever paper engineering, using folded corrugated ledges that lock into place. For products that hang, we now use high-density pressed paper hooks13 instead of plastic ones. They are surprisingly strong and fully recyclable.

Another "material" that is often overlooked is the coating. Floor displays face abuse. Mops hit the bottom; shopping carts bump the sides. We apply a varnish or an aqueous coating14 to the printed surface. This is not just for shine; it seals the paper fibers. For the bottom tray that sits on the floor, we sometimes add a clear polypropylene tape or a water-resistant mop guard. This prevents the bottom of the display from soaking up water like a sponge during store cleaning. Using the right adhesive is also part of the material science. We use vegetable-based glues15 that are strong but do not contaminate the recycling stream.

| Component | Function | Material Source | Sustainability |

|---|---|---|---|

| Support Bars | Increases shelf load capacity | Steel/Iron | Recyclable (separately)16 |

| Shelf Clips | Holds shelves in place | Plastic or Corrugated | Plastic is hard to recycle17 |

| Hang Hooks | Displays blister packs | Plastic or Pressed Paper | Paper versions are best |

| Mop Guard | Protects base from water | PVC Tape or Varnish | Necessary for durability |

We prioritize smart engineering over plastic usage. I can provide 3D renderings showing exactly where we place metal bars for strength, ensuring your display is both robust and eco-friendly.

What material is used for cardboard?

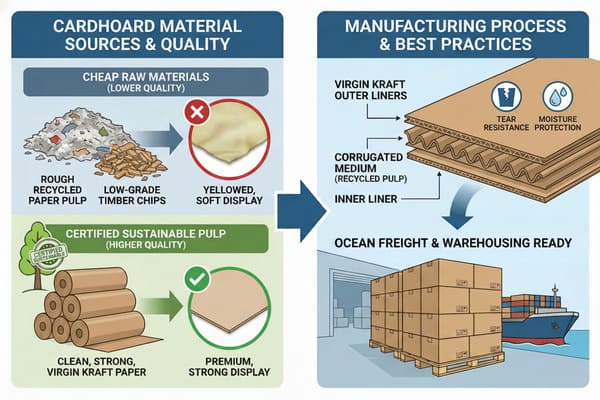

Cheap raw materials can result in displays that look yellowed or feel soft. Knowing the source of the pulp helps you verify the quality and ethical standards of your packaging.

Cardboard is manufactured from cellulose fibers derived from timber or recycled paper pulp. The highest quality displays use virgin Kraft paper for the outer liners to ensure maximum tear resistance and moisture protection during ocean freight and warehousing.

Raw Pulp Sources and Supply Chain Impact

The foundational material for all cardboard is cellulose fiber, but not all fiber is created equal. The performance of your display starts at the paper mill. There are two main sources: virgin pulp (from trees) and recycled pulp18 (from old boxes and newspapers). Virgin pulp, often called Kraft, has long, strong fibers. These fibers interlock tightly, creating a paper that is resistant to tearing and naturally repels some moisture. Recycled pulp has shorter fibers because they have been processed multiple times. This makes the paper softer and more absorbent.

For the structural walls of a display, we prefer to use at least one layer of virgin Kraft liner19, especially for the outer side. If we use 100% recycled material for everything, the display acts like a sponge. During the 30-day ocean shipment from China to the US, the salt air and humidity can weaken a fully recycled display by 30% to 40% before it even arrives. By the time it reaches the store, it looks tired.

There is also the issue of certification. Clients often worry about fake certificates regarding sustainable forestry. We only source from mills that hold valid FSC (Forest Stewardship Council) certifications20. This ensures that the virgin pulp comes from responsibly managed forests. While recycled paper21 is cheaper and good for the planet, it must be used strategically—usually in the fluting (the middle wave) rather than the outer liner—to maintain strength. We balance cost and performance by mixing these materials: Kraft on the outside for strength and looks, and high-quality recycled medium on the inside for sustainability.

| Paper Grade | Fiber Source | Strength | Moisture Resistance | Cost |

|---|---|---|---|---|

| Virgin Kraft22 | 100% New Wood Pulp | Excellent | High | High |

| Test Liner | Mix of Virgin & Recycled | Good | Medium | Medium |

| Recycled Medium23 | 100% Recycled Waste | Low | Low | Low |

| Semi-Chemical | Hardwood Pulp treated | Very High | High | High |

I personally verify our raw material suppliers to prevent quality fade. We check the paper grammage and certifications to ensure you get the strength and sustainability you paid for.

Conclusion

Choosing the right materials for your cardboard displays affects everything from shipping safety to sales performance. By understanding the difference between flute types and paper grades, you can build a display that protects your product and promotes your brand effectively.

Understanding corrugated board is essential for optimizing packaging solutions and ensuring product safety. ↩

Exploring double-wall structures can enhance your knowledge of durable packaging options for heavy products. ↩

Explore the advantages of Kraft Liner for packaging, especially its strength and moisture resistance, crucial for shipping goods. ↩

Understanding ECT standards is essential for ensuring your packaging meets retailer requirements and avoids product rejection. ↩

Discover the unique benefits of E-Flute for counter displays and small boxes, enhancing your packaging strategy. ↩

Learn how B-Flute can optimize standard floor displays, making your products stand out effectively. ↩

Explore this link to understand the unique benefits of EB-Flute for heavy products and pallet displays. ↩

Understanding CCNB is crucial for optimizing print quality and structural integrity in display boxes. ↩

Exploring lamination benefits can enhance your knowledge of protecting printed materials and improving their longevity. ↩

Exploring surface characteristics will enhance your knowledge of how they impact print results. ↩

Understanding print vibrancy can help you choose the right material for your printing needs. ↩

Explore this link to understand how 100% plastic-free displays can enhance sustainability and meet modern eco-friendly standards. ↩

Discover the strength and recyclability of high-density pressed paper hooks, a great alternative to plastic in display design. ↩

Explore this link to understand how aqueous coating enhances durability and protects printed surfaces. ↩

Discover the benefits of vegetable-based glues, including their eco-friendliness and strength, which are crucial for sustainable practices. ↩

Understanding recyclable materials helps in making eco-friendly choices and improving recycling practices. ↩

Exploring the challenges of plastic recycling can inform better waste management and sustainable practices. ↩

Learn about recycled pulp's properties and its impact on packaging performance by visiting this resource. ↩

Explore this link to understand how virgin Kraft liner enhances display strength and moisture resistance. ↩

Understanding FSC certifications helps ensure you're sourcing from responsible forestry practices, promoting sustainability. ↩

Exploring the benefits of recycled paper can enhance your knowledge of sustainable practices and cost-effective solutions. ↩

Explore the advantages of Virgin Kraft paper, known for its excellent strength and high moisture resistance, ideal for various applications. ↩

Learn about Recycled Medium paper, its uses, and how it contributes to sustainability in the paper industry. ↩