Are you wondering why some displays collapse in a week while others last months? It usually comes down to the invisible material specs your supplier chose to save pennies.

Materials used for your custom cardboard counter displays include CCNB (Clay Coated News Back) for cost-effective printing surfaces and corrugated fiberboard for structural integrity. Manufacturers also utilize SBS (Solid Bleached Sulfate) for premium brightness and recycled testliners for internal dividers to balance durability with budget constraints.

The Hidden Science of Linerboard Grades

Most buyers think "cardboard is cardboard." That is a dangerous assumption. The reality on my factory floor is that we deal with two completely different animals: Virgin Kraft and Recycled Testliner1. This is where the price wars happen, and unfortunately, where brands often get burned. I learned this the hard way years ago. A client left me for a competitor who quoted 15% less. Three weeks after their launch, they called me in a panic because their displays were "bursting" at the fold lines in humid distribution centers. The competitor had used Recycled Testliner (often 35# grade) instead of Virgin Kraft Liner2 (44# High-Performance).

Recycled fibers are short and brittle; they snap when folded tightly. Virgin fibers are long and interlock like a strong net, providing high tensile strength and moisture resistance. We also have to talk about the "ECT" (Edge Crush Test) rating. For a standard counter display, I won't touch anything below 32 ECT (5.6 kN/m)3. If we are shipping heavy liquids or batteries, we upgrade to 44 ECT (7.7 kN/m). Many factories will secretly swap 32 ECT for 26 ECT to save margin. You can't see the difference with your eyes, but the moment you stack a 50 lb (22.7 kg) load on it, the 26 ECT board buckles. It's messy, but verifying these material specs is the only way to ensure your brand doesn't end up on the floor. We even have to manage the adhesive; standard glue fails in hot trucks, so we switched to heat-resistant bonding agents4 to stop delamination.

| Linerboard Type | Fiber Source | Moisture Resistance | Cost Index | Best Use Case |

|---|---|---|---|---|

| Virgin Kraft (KL) | Pine pulp (Long fibers) | High | $$$ | Structural walls, humid environments (Florida/SE Asia) |

| Testliner (TL) | Recycled paper (Short fibers) | Low | $$ | Internal dividers, short-term promotions |

| CCNB | Recycled newsprint | Low | $ | The printable surface layer (mounted to corrugate) |

| SBS | Bleached chemical pulp | Medium | $$$$ | Luxury cosmetics, high-end electronics headers |

If you are unsure what your current supplier is using, send me a sample. I can tear a strip off and tell you immediately if it's Kraft or Testliner based on how the fibers break. I can even film the tear test for you.

What materials are best for presentation boards?

Grainy images and "wavy" surfaces make premium products look cheap. The right material choice determines whether your print looks like a photograph or a blurry mistake.

Materials best for presentation boards are E-flute corrugated board and litho-laminated paper, which prevent the washboard effect. These micro-flute profiles provide a rigid, smooth surface ideal for high-fidelity offset printing, ensuring photographic quality without the ripples found in standard packaging.

Eliminating the "Washboard Effect"

The biggest enemy of a beautiful presentation board is something we call the "Washboard Effect." This happens when you print on standard B-Flute5 cardboard. B-Flute has large waves (about 1/8 inch or 3mm thick). When the printing press applies pressure, the liner paper sinks into the valleys between the waves. The result? Your model's face on the display looks like it has stripes. It drove me crazy early in my career because clients blamed the ink, but it was purely a material structure issue. To fix this, specifically for high-end cosmetic or tech clients, I enforce a strict material switch to E-Flute6 or F-Flute. These are "Micro-flutes." They have such a tight wave pattern—about 1/16 inch (1.6mm) thick—that the surface remains perfectly flat. It provides a rigid, smooth canvas that accepts Lithographic (Offset) Lamination beautifully.

However, material isn't just about the paper; it's about the finish. We often use Clay Coated News Back (CCNB) as the top sheet for lamination. But here is the messy reality: standard CCNB is gray on the back. If your presentation board is double-sided, or if the customer sees the back, that gray looks dirty. In those cases, I have to fight the client's budget and insist on SBS (Solid Bleached Sulfate). It costs more, but it is pure white through and through. I also insist on G7 Master color calibration for the print material. We use a spectrophotometer to ensure the material absorbs ink predictably. If the paper is too porous (like raw Kraft), your "Coca-Cola Red" turns into a muddy brick color. Using the right specific material grade prevents this color shift. It's a constant battle between cost and aesthetics, but for presentation boards, aesthetics must win.

| Flute Profile | Thickness (Approx) | Flutes per Foot | Smoothness | Recommended For |

|---|---|---|---|---|

| A-Flute | 3/16" (4.8mm) | 33 | Poor | Shipping boxes (Cushioning) |

| B-Flute | 1/8" (3.2mm) | 47 | Fair | Standard floor displays, Club store pallets |

| E-Flute | 1/16" (1.6mm) | 90 | Excellent | Counter displays, Cosmetic PDQs |

| F-Flute | 1/32" (0.8mm) | 125 | Superior | Luxury packaging, Gift boxes |

I always tell clients: Do not let your designer pick the flute size based on a PDF. Let me pick it based on the print capability. I can send you a side-by-side video comparing a B-Flute print vs. an E-Flute print so you see the difference.

What are display boxes made of?

It looks like a simple box, but inside, it is a complex sandwich of engineering designed to fight gravity and humidity.

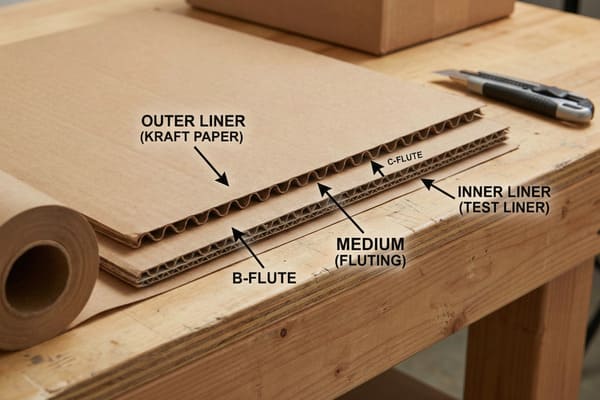

Display boxes are made of corrugated fiberboard, which consists of a fluted medium sandwiched between two linerboards. This sandwich structure utilizes grain direction engineering and starch-based adhesives to maximize stacking strength and resist humidity in retail environments.

Structural Physics and The Grain Direction7

When we ask "what is it made of," we aren't just talking about the ingredients; we are talking about the architecture. A display box is made of three distinct layers: the Outer Liner (printable), the Medium (the wavy flute), and the Inner Liner. But the secret sauce is the Grain Direction. I've seen perfectly good materials fail because a designer rotated the grain the wrong way. Corrugated board is like wood; it is incredibly strong vertically (along the grain) but weak horizontally. If we orient the grain horizontally on a load-bearing wall, the box will bulge and collapse under its own weight within days. We call this "creep." For display boxes that need to sit on a counter for 3 months, I have to ensure the structural components use Vertical Grain Orientation8 to maximize the BCT (Box Compression Test) value.

Another critical component is the Adhesive. We use corn-starch-based glues, but we add water-resistant additives. Why? Because of the "Soggy Bottom" effect. Retail floors get mopped. If the display box is made of standard starch glue and uncoated paper, it wicks up dirty mop water like a sponge. The bottom 2 inches (5 cm) turn to mush, and the box tips over. To combat this, I often specify a material addition: a Poly-coated or Varnish-sealed footer. It's a messy reality of retail that we have to engineer against. Also, regarding sustainability, we use materials that are 100% repulpable. We avoid "wet strength" wax coatings because they contaminate recycling streams. We use water-based alternatives so the box is fully "Curbside Recyclable9" in the US.

| Component | Material | Function | Critical Spec |

|---|---|---|---|

| Medium | Recycled Fluting | Provides cushioning & stacking strength | Vertical Grain Direction |

| Adhesive | Starch + Resin | Bonds the layers | Heat/Moisture Resistant |

| Outer Liner | Coated Duplex | Provides print surface | Smoothness (Parker Print Surf) |

| Coating | Water-based Varnish | Protects ink & repels water | Abrasion Resistance |

It sounds technical, but getting the grain direction and glue right is the difference between a display that sells and one that smells like moldy water. I can show you the compression test video where we crush these boxes to see exactly when they fail.

What are cardboard displays called?

Using the wrong terminology can lead to expensive manufacturing errors and retailer rejection.

Cardboard displays are called POP (Point of Purchase) displays or POSM (Point of Sales Material) units. Specific types include PDQ (Pretty Darn Quick) trays for counters and FSDU (Free Standing Display Unit) structures for floor aisles, defined by their retail placement.

Decoding the Industry Alphabet Soup

In this industry, "Cardboard Display" is too vague. If you tell me you need a "Display," and I quote you a PDQ, but you actually wanted a Pallet Skirt, we are going to have a very bad day. The terminology dictates the material specs and the retailer compliance rules. For example, a PDQ (Pretty Darn Quick) or SRP (Shelf Ready Packaging) usually refers to a small tray sitting on a shelf or counter. It needs to be E-Flute or B-Flute. But if you ask for a "Half Pallet" or "Quarter Pallet", that is a totally different beast. Those are heavy-duty logistics units that must fit the standard US GMA Pallet size of 48×40 inches (122×102 cm). I once had a client call everything a "Standee." In the US, a Standee is a flat cutout of a movie character. They actually needed an FSDU10 (Free Standing Display Unit) with shelves to hold 50 lbs (22.7 kg) of product. If I had built them a "Standee," it would have collapsed instantly.

Furthermore, retailers like Walmart and Costco have their own languages. Costco demands "Club Store" packaging, which implies virtually indestructible, shop-through structural designs that can support 2,500 lbs (1,134 kg) of dynamic load. Walmart focuses on "RPCS11" (Reusable Plastic Container) compatibility or specific corrugated footprints. We maintain an internal database of these "Retailer Dialects" to ensure that when you say "Display," we build exactly what the store manager expects to receive. Misunderstanding these terms creates compliance fines. For example, if a "Sidekick" display (Power Wing) doesn't have the correct metal bracket for a standard US Lozier gondola shelf, it gets rejected by the store manager.

| Acronym | Full Name | Typical Location | Key Characteristic |

|---|---|---|---|

| POP | Point of Purchase | Anywhere in store | General term for all displays |

| PDQ | Pretty Darn Quick | Counter / Shelf | Pre-packed, tray style |

| FSDU | Free Standing Display Unit | Aisle Floor | Standalone, multiple shelves |

| Endcap | End of Aisle Display | End of Gondola | High traffic, strict dimensions |

| Sidekick | Power Wing | Hanging on side | Requires specific metal brackets |

Miscommunication here is the number one cause of project delays. I usually ask clients to send a photo of a similar display in a store, just to be 100% sure we are speaking the same language.

Conclusion

Choosing the right materials isn't just about cost; it's about survival in the retail jungle. Whether it's resisting the mop water on the floor or surviving a drop test in a 40HQ container, the specs matter. Would you like me to send you a Free Structural 3D Rendering or a physical White Sample so you can test the durability yourself?

Explore this link to understand the properties and uses of Recycled Testliner in packaging. ↩

Discover why Virgin Kraft Liner is preferred for high-performance packaging solutions. ↩

Learn about the importance of ECT ratings in ensuring packaging strength and durability. ↩

Find out how heat-resistant bonding agents enhance the performance of packaging materials. ↩

Explore this link to understand the characteristics and applications of B-Flute cardboard, crucial for avoiding the Washboard Effect. ↩

Learn about E-Flute's advantages for high-quality presentations and how it can enhance your display's appearance. ↩

Understanding grain direction is crucial for material strength and durability, especially in construction and design. ↩

Exploring this will reveal how grain orientation maximizes strength and stability in packaging design. ↩

Discover the best sustainable practices for recycling packaging materials effectively. ↩

Exploring FSDUs will provide insights into effective display solutions that maximize product visibility and sales. ↩

Discover the benefits of RPCS for efficient product handling and compliance in retail environments. ↩