Many buyers need strong packaging. Many also want a premium look. They feel pressure from shelf competition. I show a clear path. I explain tin packaging in simple steps.

Tin packaging is a metal container made from tinplate or tin-free steel with protective lacquer. It gives strong barriers against light, oxygen, moisture, and impact. It suits food, tea, coffee, confectionery, cosmetics, candles, and gifts, and it is widely recyclable.

I share what works in factories and on shelves. I also work with cardboard displays, so I compare how tins and displays play together in retail sets. I keep the advice simple and practical.

What is a tin packaging?

Shoppers judge by touch and shine. Many brands want that feel. Teams still worry about safety and print quality. I explain the core parts and how a tin is built.

Tin packaging is a formed metal container made from coated steel sheets, printed and lacquered, then cut, stamped, curled, and seamed to hold and protect products while delivering a premium look.

How a tin comes to life

A tin starts as a flat sheet. The sheet is steel with a thin tin coat or chrome coat. Printers add ink and varnish. Tooling cuts and forms the panels. Edges curl to remove sharpness. The lid and body join with a seam or a friction fit. Internal lacquer protects food or wax from metal contact. Engineers test seams, drop strength, and corrosion. I run mock loads to copy real retail shocks. I learned this after a holiday tea launch when lids popped in transit. We fixed the curl radius and added an inner plug. The return rate dropped to near zero.

Common materials and features

| Item | What it is | Why it matters |

|---|---|---|

| Tinplate steel | Low-carbon steel with tin coat | Resists rust, good for food |

| Tin-free steel (TFS) | Chrome-coated steel | Harder surface, sharp print |

| Internal lacquer | Epoxy-phenolic or BPA-NI options | Food contact safety |

| External varnish | Gloss, matte, soft-touch | Brand feel and scratch resistance |

| Closures | Slip lid, hinged lid, lever, seamed | Usability and aroma control |

| Forming | Drawn or rolled body | Cost, height limits, and speed |

| Decoration | Offset print, emboss, deboss, foil | Shelf impact and storytelling |

I match tin sizes to cardboard floor or pallet displays. A tight grid avoids wobble in stores. I also lock tin lids with heat-shrink bands when chains ask for tamper signs. This reduces returns and builds trust.

What are the benefits of tin packaging?

Many teams chase premium looks and long shelf life. Budgets still matter. I list the real wins so you can defend the choice in a meeting.

Tin packaging protects against light, oxygen, and moisture, carries high-impact graphics, supports giftable forms, stacks well in displays, resists crush in transit, and is recyclable in mature metal streams.

Value you can measure

Tin protects aroma and flavor for tea, coffee, and spices. It blocks light better than most plastics. It survives long ocean trips and rough DC handling. It keeps shape after minor dents, so the brand face stays flat. Printers hit tight lines and metallic sheens, so logos look sharp under store LEDs. I map these gains against real cost. Tooling adds setup fees, yet repeat runs spread that cost. For holiday sets, tins often drive higher AOV because people gift and keep them. I watch this in North America and Europe where premium seasonal packs1 perform well. In Asia-Pacific, gift culture2 boosts tins even more.

| Benefit | What you see | What you save or gain |

|---|---|---|

| Barrier | Fresher taste, less fade | Fewer returns, longer code life |

| Strength | Less crush and scuff | Lower damage rates |

| Premium look | Emboss and matte-gloss play | Higher price points |

| Reuse | Consumers keep boxes | Extra brand exposure |

| Recyclability | Fits metal streams | Better sustainability claims |

| Stackability | Clean planograms | Faster shelf work |

I pair tins with cardboard PDQ trays for clubs like Costco. The tray carries copies of the lid art. The set looks clean. The load tests pass. The sell-through rises.

Is tin better than plastic?

Teams ask this first. There is no single winner. The right answer depends on product, volume, and brand story. I give a direct view.

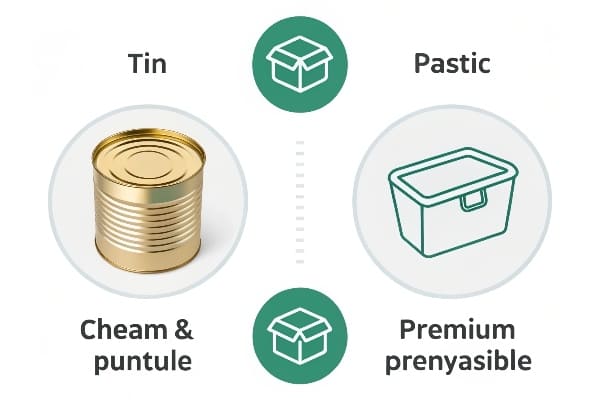

Tin is better when you need premium look, high barrier without multi-layer films, strong shelf impact, and metal recycling claims; plastic is better when weight, see-through display, and very low unit cost matter.

Choose by use case, not by habit

I compare on six points. First, barrier. Tin blocks light and oxygen with one wall. Many plastics need layers or foils. Second, impact. Tin keeps faces flat after minor hits. Third, design. Emboss and deboss add touch. Plastics allow clear windows and organic shapes. Fourth, cost. Plastic molds cost more upfront but run fast at scale. Tin tooling is simpler for rectangles and rounds, yet sheet prices move with metal markets. Fifth, sustainability3. Tin recycles well in many countries. Some plastics recycle too, but streams vary. Sixth, retail. Tin pops on gift shelves and seasonal power aisles. Plastic wins for everyday refills.

| Factor | Tin | Plastic |

|---|---|---|

| Barrier | Excellent without layers | Varies; needs multi-layers for high barrier |

| Look and feel | Premium, tactile emboss | Clear view, fluid shapes |

| Unit weight | Heavier | Lighter |

| Cost at low volume | Competitive | Tooling can be high |

| Cost at very high volume | Good, depends on steel | Often lower per unit |

| Recyclability | Strong in many markets | Mixed by resin and region |

| Retail gift appeal | Very strong | Moderate unless special |

I once ran a tea campaign with a tin for the gift set and a pouch for refills. The mix gave margin and repeat orders. The display used cardboard floors with a gift tower in the center. The set outsold the pouch-only test by a wide margin.

What is a tin pack?

People use this term in meetings with different meanings. I use a clear one, so teams align fast across design, ops, and buying.

A tin pack is a retail-ready bundle where the primary container is a printed tin, often combined with an insert, a label or belly band, and a display-ready outer carton.

What sits inside a full tin pack

A tin pack is more than a can. It is a system. The tin is the hero. An inner fitment4 holds the product. Foam or paper keeps it stable. A band or label carries legal copy and seals the lid without glue. A barcode sits on the belly band or on a base label. The outer carton arrives shelf-ready. For clubs and big box stores, I place 6 to 12 tins into a PDQ tray5. The tray fits a pallet pattern. It passes drop tests and clamp tests. The art repeats on the tray skirt, so the set looks unified.

| Component | Role | Notes |

|---|---|---|

| Printed tin | Primary container | Emboss logo, matte or gloss |

| Inner fitment | Hold product | Paperboard, pulp, or EVA |

| Seal | Belly band or shrink | Tamper-evident, easy open |

| Base label | UPC and claims | Batch and date code space |

| PDQ tray | Shelf-ready unit | Fits club or grocery shelf |

| Master carton | Transport | Edge crush strength targets |

I set checkpoints to avoid surprises. I lock metal gauge. I approve lacquer type. I run color drawdowns on metal, not paper. I print a few sheets and cut them into mock tins. I test lids for air gap and friction. I stack tins in the real PDQ and shake the set for one minute. When I follow these steps, I hit launch dates and avoid costly rework.

Conclusion

Tin packaging gives strong protection, premium shelf appeal, and solid recycling stories. I pair tins with smart cardboard displays to win speed, safety, and sell-through.

Explore this link to understand how premium seasonal packs can enhance your product's appeal and sales. ↩

Discover insights on how gift culture impacts consumer behavior and packaging strategies. ↩

Explore the importance of sustainability in packaging to understand how it impacts the environment and consumer choices. ↩

Understanding the role of inner fitments can enhance your packaging design, ensuring product stability and safety. ↩

Exploring PDQ trays can help optimize your product display strategies, making your items more appealing on store shelves. ↩