I know MOQ can block a good idea. I also know budgets are real. I keep this simple so buyers move fast without waste.

Most factories set MOQs between 50–200 units for simple countertop displays and 100–500 units for floor or pallet units; digital printing lets me do 20–50 pilot units, while offset printing needs 300–500+ to hit best unit cost.

I explain ranges with real factory math, not vague talk. I show how print method, size, and finish change MOQ. I include a small story from my shop floor, so you see how I decide when a lower test run makes sense.

What are cardboard displays called?

Many buyers use many names. That creates confusion in quotes. I keep one clear list and map it to retail needs.

Cardboard displays are commonly called POP or POS displays, including floor displays, countertop displays, PDQ trays, pallet displays, dump bins, end caps, and standees.

Terms that matter in real projects

I use simple names because buyers and store teams pick faster when we speak the same language. I split by where the unit sits in store and by how much it holds. I also mark the setup speed1, since labor time can kill a rollout. I learned this the hard way during a nationwide launch for an outdoor brand. The plan looked perfect. The problem was the store team had five minutes, not fifteen. We switched from a multi-shelf tower to a PDQ tray on an existing shelf. The sell-through rose, and the returns dropped. The lesson was clear. Use the right name and the right spot.

Store placement types

| Display name | Where it sits | Typical use | Setup time | Notes |

|---|---|---|---|---|

| Floor display | Aisle or power aisle | New launch, bundles | 10–20 min | Strong branding, higher MOQ |

| Countertop | Checkout or service desk | Impulse items | 2–5 min | Lowest MOQ, fast to pack |

| PDQ tray | Existing shelf | Small items, trial sizes | 2–5 min | Ships pre-packed |

| Pallet display | Warehouse clubs | Large volume | 15–30 min | Ships on pallet, drop-in |

| Dump bin | Open bin on floor | Clearance, mixed SKUs | 5–10 min | Simple print, robust walls |

| End cap | Aisle end | Seasonal push | 15–25 min | Often retailer spec-driven |

| Standee | Entrance or promo zone | Brand story, QR | 5–10 min | Light, add brochure pocket |

I keep these labels in every quote and drawing. That avoids redesign loops and speeds approvals.

What is the HS code for cardboard displays?

Import codes worry many buyers. Wrong codes delay shipments. I set the right HS code before I start printing.

Most paper-based POP displays ship under HS 4819.60 or 4823.90 depending on structure and use; confirm with your customs broker for your product mix and destination.

How I choose the correct HS code

I do not guess HS codes2. I check structure, intended use, and any non-paper parts. I ask if the unit functions as packaging or as a display fixture only. I then share the code and a material breakdown on the PI. This prevents disputes at the border. I had a case with a hunting-gear brand in the United States. The display carried heavy crossbow accessories. We added a thin metal bracket for safety. The broker asked for clarification. I provided a parts list with exact weights. The shipment cleared without reclassification. The key was transparency3.

Practical classification checklist

| Item | Why it matters | What I document |

|---|---|---|

| Primary material | Paperboard vs mixed | GSM, flute, recycle content |

| Function | Packaging vs display | Whether it holds sellable goods in transit |

| Added parts | Metal, acrylic, LEDs | Weight %, purpose, removability |

| Print/finish | Coatings, lamination | Type (water-based, film), recyclability |

| Country rules | Local notes | USMCA/EU rules of origin if relevant |

I also mark cartons with plain English names. This helps warehouse teams and reduces inspections.

What are the three types of cardboard?

People say "cardboard" but mean many things. I break it into three simple groups used in displays.

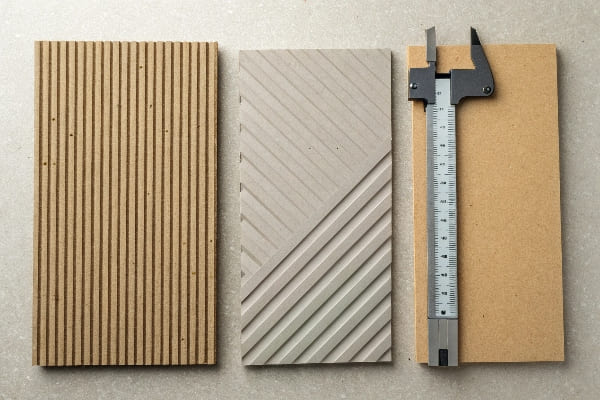

The three common types are corrugated cardboard, paperboard (folding carton), and honeycomb board; each has different strength, print options, and cost, so I match type to load and shelf life.

Picking the right board for your job

I choose board based on weight, time in store, and brand finish. I also look at humidity4, because a damp store kills a weak spec. I once shipped a floor tower to a coastal region. The first batch used E-flute with spot lamination. It looked great but softened after two weeks. We changed to BC double-wall5 with a water-based barrier and widened the base by 20 mm. Returns stopped. The fix was not fancy. It was the right board for the climate.

Comparison table

| Type | Structure | Best for | Pros | Cons |

|---|---|---|---|---|

| Corrugated | Fluted core between liners | Floor towers, pallet units | Strong, many flute choices | Higher MOQ with offset print |

| Paperboard | Solid sheet | Countertops, sleeves | Sharp print, low MOQ | Lower stiffness, add inserts |

| Honeycomb | Hex core, thick | Pallet skirts, risers | Very stiff, light | Bulkier, higher unit cost |

Flute quick guide

| Flute | Thickness (approx.) | Use case | Note |

|---|---|---|---|

| E | 1.5–2 mm | Countertops, trays | Fine print, neat edges |

| B | 3 mm | Shelves, mid-load | Good balance |

| C | 4 mm | Heavier floors | Better crush resistance |

| BC (double) | 6–7 mm | Heavy towers | Strong, fewer lean issues |

I sample early when the display must hold metal tools or outdoor gear. I also run load and drop tests before mass runs.

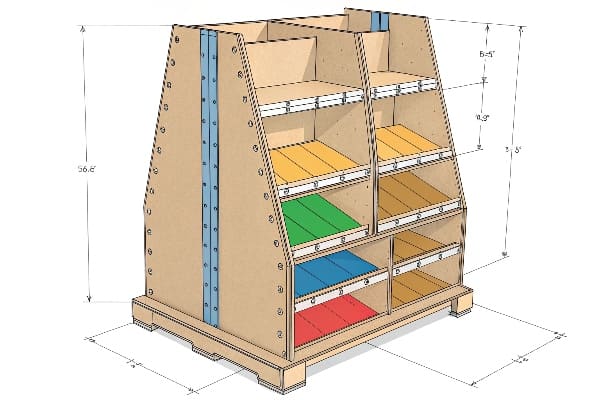

How to make a cardboard display stand up?

Stability sells products. A leaning rack loses trust. I design stand-up strength from the first sketch.

Use the right base width, double-wall or cross braces for tall units, tab-lock joints over glue-only, and test with real product weight; add shrouds or feet if floors are uneven.

My step-by-step method that stops leaning

I start with the product map. I place heavy SKUs6 at the lowest shelf. I keep the center of gravity low. I set the base depth to at least 35–45% of display height for narrow towers. I add a kick plate to resist toe hits. I prefer tab-and-slot joints7 because store teams work fast with no tools. For hunting gear displays, I often add hidden L-braces at shelf corners. These small parts take seconds to fold, but they add days of life in store. I had one tight launch window for a crossbow accessory rack. The client needed 200 units in three weeks. We ran a digital-printed pilot of 25. We found a shelf deflection8 at 8 kg. We adjusted the span and added a bridge. The full run shipped on time and stood straight.

Stability checklist

| Factor | Target | Why |

|---|---|---|

| Base-to-height ratio | ≥ 0.35 for towers | Stops forward tip |

| Material spec | B/C flute or BC | Limits bowing |

| Joint type | Tab-lock + limited glue | Faster, stronger |

| Shelf span | ≤ 400 mm for heavy SKUs | Reduces sag |

| Back panel | One-piece or overlapped seam | Adds stiffness |

| Feet/shims | Include for uneven floors | Field-friendly fix |

Quick test plan

| Test | Load | Duration | Pass criteria |

|---|---|---|---|

| Static load | 1.5× planned weight | 24 hours | No lean >5 mm |

| Drop test | 30–60 cm, flat pack | 3 drops | No tear at tabs |

| Humidity hold | 60–70% RH | 48 hours | Shelf deflection <3 mm |

| Assembly time | 1 person | <8 minutes | No tools needed |

I give teams a one-page setup guide with photos and a QR code for a short video. This saves time and reduces damaged parts.

Conclusion

MOQ depends on print, size, and load. Choose the right board and joints. Plan stability with tests. Small pilot runs prevent risk and speed confident rollouts.

Understanding setup speed can significantly enhance your rollout efficiency and reduce labor costs. ↩

Understanding HS codes is crucial for smooth customs clearance and avoiding disputes at the border. ↩

Exploring the importance of transparency can help you ensure compliance and prevent issues during shipping. ↩

Learn about the impact of humidity on packaging materials to make informed choices for your products. ↩

Explore this link to understand why BC double-wall is ideal for heavy-duty packaging, ensuring durability and reliability. ↩

Understanding heavy SKUs is crucial for effective product placement and display stability. ↩

Explore how tab-and-slot joints enhance assembly speed and strength in retail displays. ↩

Learn about shelf deflection to ensure your displays remain stable and effective. ↩