I have seen products fail because the first impression was weak. That moment on the shelf is short. A smart package can save the sale. I know the pressure.

The main purpose of packaging and boxes is to protect the product, present the brand, give information, and streamline logistics, all while shaping the customer’s first emotional response.

Many readers stop after they hear “protection.” They miss the money left in branding, data, and shipping. Stay with me and we will open every layer of value.

What are the main purposes of packaging?

Every launch faces damage, mixed messages, and wasted freight space. These pain points cut profit.

Packaging keeps the item safe, sells the story fast, provides clear facts, and lowers handling cost.

Four Core Goals

A simple framework helps my factory team design displays that earn repeat orders.

| Goal | What it Solves | Real-World Case |

|---|---|---|

| Protection1 | Shocks, moisture, dust | Crossbow limbs stay aligned after ocean transit |

| Promotion2 | Shelf attraction, impulse buy | Bright hunting scene graphics draw shoppers |

| Information | Laws, care, specs | QR code links to safety video |

| Efficiency3 | Stack, store, ship | Flat-pack design saves 20% warehouse space |

Why Each Goal Matters

I once watched a retailer reject an entire pallet of displays because corners were crushed. Protection is not just foam; it is trust. Promotion feeds that trust by confirming the brand promise in seconds. Information cuts buyer doubt, which raises conversion. Efficiency glues the supply chain. When boxes slot neatly, forklifts move faster, fuel costs drop, and deadlines hold. A missed launch window means lost hunting season sales. Good packaging pays for itself long before the cashier scans the barcode. In my plant, we run transport tests that mimic three weeks on rough highways. If a sample fails, we redesign joints, not just add tape. That mindset keeps long-term clients like Barnett Outdoors returning.

What is the purpose of a box?

Products live rough lives from factory to front door. Edges chip, labels peel, and rain finds gaps.

A box encloses the product in a rigid shell that resists impact, organizes units, and carries brand signals outward.

Box as Silent Salesperson

A box is more than folded board. It speaks without words.

| Feature | Customer Benefit | Supply Chain Benefit |

|---|---|---|

| Structural walls | Item arrives unbroken | Pallets stack tall without crush |

| Printed panels | Spot product from aisle | Fast SKU picking in warehouse |

| Barcodes & NFC | Quick checkout | Track inventory in real time |

Case Study From My Line

When we built a corrugated carrier for a new broadhead set, the buyer feared blade rattle. We created double-wall end caps4 that lock each tray. Drop tests at 1.2 m on all corners showed zero movement. We printed a hunting scene that matches online ads. Store staff said they could restock by color code alone, cutting shelf time in half. Profit rose because returns fell and display labor dropped. A box, done right, became a quiet assistant that works every hour.

What is the primary purpose of packing?

Even the best product fails if it cannot cross borders intact.

Packing unites protective materials and placement methods to stop shock, damp, theft, and miscount during transit.

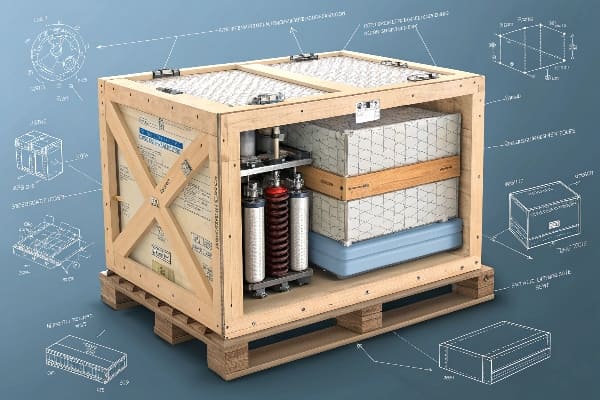

Layers Work Together

I pack displays like armor: skin, muscle, bone.

| Layer | Material | Task |

|---|---|---|

| Inner | Foam, paper wrap | Cushion delicate faces |

| Middle | Honeycomb board | Absorb heavy hits |

| Outer | Master carton | Resist puncture |

Small Tweaks, Big Savings

We switched from loose bubble wrap to die-cut inserts5 for a client’s compound bow risers. The snug fit trimmed fill time by 30 %. Freight bills fell because void space6 shrank. Customs officers opened one box, saw neat rows, and waved the lot through. No extra inspections saved days. Good packing is not guesswork; it is measured in fewer claims and faster cash flow.

What is general purpose packaging?

Market lines blur when one solution must serve many products. I meet buyers who need “one box for all.”

General purpose packaging offers a standardized, cost-effective container that fits multiple items with minor inserts or print changes.

When to Choose Versatility

Standardizing works when product sizes sit in a narrow band.

| Scenario | Advantage | Caution |

|---|---|---|

| Seasonal kits | Bulk order lowers price | May waste space for small items |

| New launches | Speeds time to shelf | Generic look can weaken brand |

| E-commerce mix | Simplifies warehouse | Risk of overpacking fragile goods |

Balancing Flexibility and Identity

At Popdisplay, I keep shelves of blank die-cut cartons ready. By sliding in a printed sleeve7, we turn a plain box into a brand billboard overnight. This method saved a sporting-goods client who changed artwork days before shipping. They avoided airfreight charges by updating only the sleeve, not the carton cut. Yet I warn against chasing one-size-fits-all blindly. If inserts do not align, breakage costs outweigh the savings. I run a simple formula: if internal void exceeds 15 %, custom fits8 win. General purpose must never mean generic experience. My rule is clear print, snug interior, and quick assembly. When these align, the same box can carry crossbow bolts today and fishing reels tomorrow without compromise.

Conclusion

Great packaging shields, sells, informs, and moves products with less waste, turning a box from mere container into silent profit engine.

Explore this link to understand how effective packaging protection can enhance trust and reduce product damage during transit. ↩

Discover insights on how packaging promotion can attract shoppers and boost impulse buys, essential for retail success. ↩

Learn how efficient packaging design can streamline operations, reduce costs, and improve overall supply chain performance. ↩

Explore how double-wall end caps enhance product protection and improve supply chain efficiency. ↩

Explore how die-cut inserts can enhance packaging efficiency and reduce costs, making them a smart choice for businesses. ↩

Understanding void space can help optimize packaging, leading to cost savings and improved shipping efficiency. ↩

Explore how printed sleeves can enhance branding and flexibility in packaging, making your products stand out. ↩

Learn why custom fits can prevent damage and improve product presentation, ensuring a better customer experience. ↩