Confusing these two materials is the fastest way to destroy a product launch. One is a simple sheet meant for cereal boxes; the other is an engineered structure designed to survive global shipping logistics.

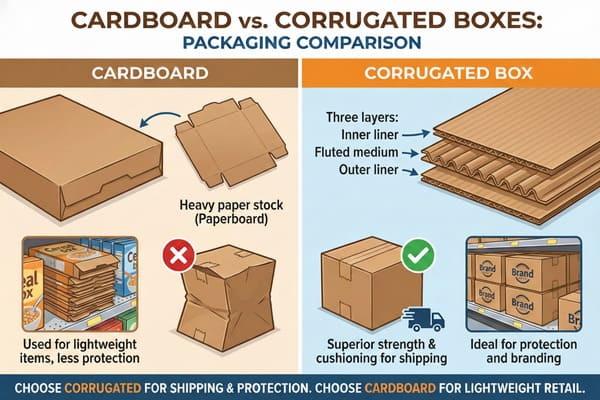

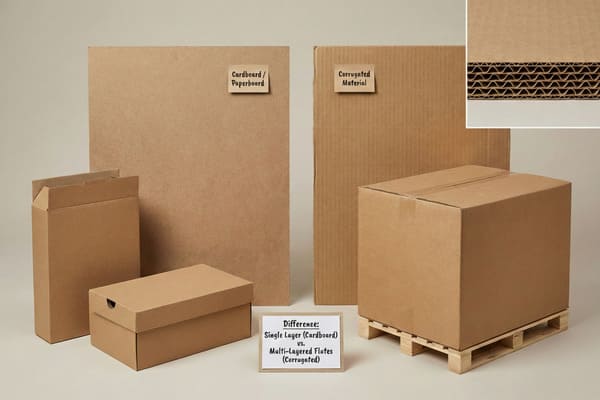

The difference between cardboard and corrugated boxes is their structural composition and load-bearing capacity. Cardboard is a single-layer, heavy-duty paper stock used for lightweight consumer packaging, whereas corrugated boxes are constructed from three layers—an inner liner, an outer liner, and a fluted medium—engineered to provide crush resistance and stacking strength.

Let's break down the engineering physics that separate a flimsy carton from a shipping vessel capable of handling 50 lbs (23 kg) without buckling.

What's the difference between corrugated and cardboard?

Most buyers use these terms interchangeably, but on the factory floor, this confusion leads to catastrophic structural failures during transport.

The difference between corrugated and cardboard is that cardboard is a single-ply heavy paper stock, whereas corrugated board is a multi-layered structure containing a fluted medium. This fluting acts as a series of arches, providing significant rigidity and insulation, which allows corrugated material to support heavy vertical loads that would crush standard cardboard.

The Structural Anatomy of Paper Engineering

I deal with this terminology mix-up every single week. A client sends a design file asking for "cardboard" for a floor display, but what they really need is high-grade corrugated board. Here is the messy reality: "Cardboard," often referred to in the industry as Folding Carton, Chipboard, or CCNB (Clay Coated News Back), is essentially just thick paper. It has zero structural memory1. If you bend it, it creases permanently. It relies entirely on the product inside—like a bag of cereal or a tube of toothpaste—to hold its shape. If you stack five empty cardboard boxes, the bottom one will crumple immediately.

Corrugated board2, on the other hand, is an engineered sandwich. It relies on the architectural principle of the "arch." The inner medium—the wavy fluted part—is the secret weapon. In my factory, we strictly orient this grain direction vertically to maximize stacking strength. I learned this the hard way years ago. A designer oriented the grain horizontally on a load-bearing wall to save material costs. It looked fine on the sample table, but once it hit a humid truck in Florida, the entire pallet collapsed like an accordion. That mistake cost me a reprint of 500 units.

Furthermore, the quality of the paper liner matters just as much as the structure. Many competitors use "Recycled Testliner3" for the outer layers to undercut prices. But recycled fibers are short and brittle. They break easily under stress, leading to ugly cracking at the fold lines, especially in dry climates like Nevada. That is why I often insist on using High-Grade Virgin Kraft Liner4 for structural components. The long fibers in Virgin Kraft provide superior tensile strength, preventing the box from bursting open when dropped. It might cost 5% more, but it stops your display from looking "tired" and cracked before a customer even touches it.

| Feature | Cardboard (Folding Carton/CCNB) | Corrugated Board (Containerboard) |

|---|---|---|

| Structure | Single layer, solid pulp | 3+ Layers (Liner – Flute – Liner) |

| Primary Strength | Tensile (Surface only) | Compressive (Stacking strength) |

| Thickness | 0.010" – 0.030" (0.25mm – 0.8mm) | 0.062" – 0.250" (1.5mm – 6mm) |

| Common Use | Cereal boxes, cosmetic cartons | Shipping boxes, Floor Displays, POP |

| Moisture Resistance | Low (Warping common) | Moderate to High (with additives) |

When we run a production batch, I personally check the fold lines. If I see "bursting" or white cracks on the edges, I know the paper grade is too low or the humidity in the plant is off. I tell my clients: spending a few pennies more on the right liner prevents your premium brand from looking like a budget knock-off.

What is the difference between corrugated and non corrugated boxes?

Choosing the wrong box type destroys brand perception instantly. Non-corrugated screams "cheap disposable," while corrugated says "durable and premium," provided you use the right finish.

The difference between corrugated and non corrugated boxes is their intended application and structural integrity. Non-corrugated boxes, such as folding cartons, are lightweight and primarily used for shelf presentation of individual retail items, while corrugated boxes are designed for secondary packaging, offering shock absorption and the durability needed for shipping and handling.

Strategic Application in Retail Environments

From a marketing perspective, the choice between these two defines how the shopper interacts with your product. Non-corrugated boxes, usually made from SBS (Solid Bleached Sulfate) or Chipboard, offer a smoother, magazine-like printing surface. This is perfect for high-resolution graphics on small, lightweight items like cosmetics or iPhone cases. However, they are physically weak. They cannot support their own weight if you try to build a freestanding display out of them. They are strictly "primary packaging."

Corrugated boxes used to be considered ugly—brown, rough, and industrial. But that has changed dramatically. The big trend I am seeing now is the "Premium Look5" on corrugated. We use a material called E-Flute6 or Micro-Flute. The waves are so tight and small that you can hardly see them. This eliminates the dreaded "Washboard Effect"—where the corrugated waves show through the ink, making a human face on a poster look like it was printed on a radiator. By using E-Flute, we get the structural rigidity of a shipping box with the print quality of a luxury perfume carton.

I had a client who insisted on using standard non-corrugated card stock for a Countertop Display (PDQ) because they wanted it to look "sleek" and save money. I warned them about the "Tipping Point7" physics. As soon as customers bought the first few items from the front, the center of gravity shifted backward. Because the card stock was too flimsy to hold a counter-weight, the whole display tipped over backward. We had to rush a reprint using E-Flute corrugated with a weighted false bottom to fix it. The lesson? You can't cheat physics with card stock. Also, for brands looking for sustainability, we are seeing a push for "Mono-Material8" designs. Using corrugated for both the insert and the outer box means the customer can toss the whole thing in the recycling bin without separating plastic trays.

| Feature | Non-Corrugated (Carton) | Corrugated (E-Flute/B-Flute) |

|---|---|---|

| Print Quality | Excellent (Photo-realistic) | Good to Excellent (with Litho-Lam) |

| Stackability | Poor (Requires shelving) | Excellent (Self-supporting) |

| Cushioning | None | High (Shock absorption) |

| Best For | Primary Product Packaging | Secondary Packaging & Displays |

I often have to be the bad guy in design meetings. Designers love thin card stock because it is easy to fold into complex origami shapes. I have to remind them that once that display hits a Walmart shelf, it is going to get hit by shopping carts and mopped by janitors. Corrugated takes the hit; card stock crumbles.

What is a corrugated box?

It is not just a box; it is an engineered shipping vessel. If you don't understand the specific rating stamped on the bottom, your shipment will likely get rejected by the Distribution Center (DC).

A corrugated box is a shipping container engineered from multi-layered paperboard designed to withstand stacking pressure. These boxes feature specific strength ratings, such as ECT (Edge Crush Test) values, ensuring they meet logistics standards. The fluted geometry distributes weight, preventing collapse under heavy vertical loads during supply chain operations.

Technical Specifications and Logistics Compliance

When we talk about a "corrugated box" in the US market, we are really talking about compliance and survival. Every box has a stamp on the bottom, usually the BMC (Box Manufacturer's Certificate). If you ship to Walmart or Costco, they don't care about your pretty graphics; they care about the ECT rating. ECT stands for Edge Crush Test9. It measures exactly how much weight a single linear inch of the cardboard can support vertically before it crumples.

Competitors play a dirty game here called the "Material Spec Deception10." They quote you a price for a 32 ECT box (standard strength) but secretly use a lower grade liner with recycled fibers that only tests at 26 ECT. It looks the same to the naked eye. But give it three days in a humid warehouse or a sea container, and it absorbs moisture. The strength drops by 40%, and the bottom box in the stack collapses, crushing your product. This is why I treat the paper grade as a non-negotiable contract spec.

We solve this by strictly adhering to the "Grain Direction11" rule. The flutes must run vertically. I once saw a batch from another factory where they rotated the grain to save scrap paper during cutting. It saved them 4% in material cost, but the boxes had zero vertical strength. They arrived at the port crushed. For my clients, especially those shipping to the US, we use High-Performance Kraft liners12 to guarantee we hit the 32 ECT or 44 ECT targets. We also integrate "Mop Guards"—water-resistant coatings on the bottom—because we know store employees mop floors with dirty water that destroys standard corrugated bases. If you don't account for the "mop factor," your box is just a sponge waiting to fail.

| Grade (US Standard) | Structure | Max Load per Carton (Approx) | Recommended Use |

|---|---|---|---|

| 32 ECT | Single Wall (C-Flute) | up to 40 lbs (18 kg) | Standard Shipping |

| 44 ECT | Single Wall (C-Flute) | up to 65 lbs (29 kg) | Heavy Retail Items |

| 48 BC | Double Wall (B+C Flute) | up to 100 lbs (45 kg) | Pallet Displays / Heavy Tools |

| 51 ECT | Double Wall | up to 120 lbs (54 kg) | Industrial Parts |

I openly invite my clients to send my production samples to third-party labs for blind testing. I quote based on Guaranteed US Performance Specs, not just the cheapest paper I can find that day. It is the only way to sleep at night knowing the shipment won't implode.

Is corrugated cardboard stronger than regular cardboard?

Yes, but strength is relative. Using the wrong "strong" box leads to wasted freight costs and "shipping air," while under-engineering leads to lawsuits and recalls.

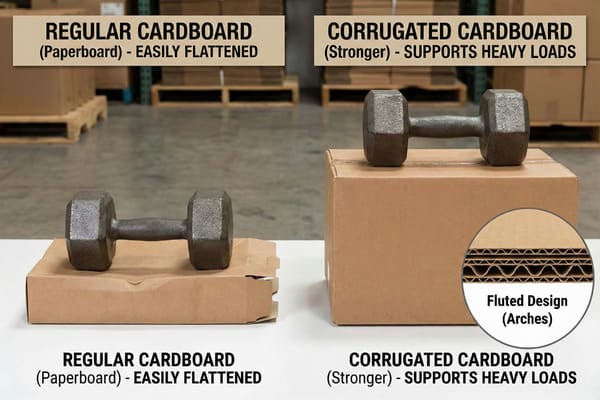

Yes, corrugated cardboard is significantly stronger than regular cardboard due to its fluted internal medium. This structural design offers superior BCT (Box Compression Test) ratings, allowing it to support heavy stacking loads during transport. Regular cardboard lacks this reinforcement and will buckle under even minimal vertical pressure.

Load Bearing Physics and Safety Factors

The answer is a definitive yes, but here is the nuance: Corrugated is only stronger if we engineer it for the specific environment. In the US, liability is a massive concern. If a Pallet Display collapses and hurts a child in a store, the lawsuit is massive. Standard testing just for "holding product weight" isn't enough. We have to account for real-world chaos.

We use a "Safety Factor of 3.513." This drives some clients crazy because they think I'm over-engineering and wasting material. But here is the physics: Cardboard loses 30-40% of its strength in humid environments. A box that holds 100 lbs (45 kg) in my dry factory in China might only hold 60 lbs (27 kg) in a humid Florida distribution center. By designing the box to withstand 350 lbs (158 kg) before failure (Safety Factor 3.5), I guarantee that even after "Humidity Fatigue" sets in, the structure remains rock solid.

We also have to pass the ISTA 3A Testing Standards14. This includes dropping the packaged unit from 30 inches (76 cm) and vibrating it to simulate a truck driving over potholes. Regular cardboard would disintegrate instantly under this stress. For Club Stores like Costco, the requirements are even crazier—they demand the display supports 2,500 lbs (1,133 kg) of dynamic load because they stack full pallets on top of each other. To achieve this, we insert internal "H-Dividers" or steel support bars into the corrugated structure. It's engineering, not just packaging. If you just guess the strength, you will fail the audit.

| Feature | Regular Cardboard | Corrugated (Engineered) |

|---|---|---|

| Safety Factor | 1.0 (No margin) | 3.0 – 5.0 (Heavy Duty) |

| Humidity Impact | Warps immediately | Retains 60-70% strength (if treated) |

| Drop Test (ISTA) | Fails | Passes (with buffer zones) |

| Max Stack Height | N/A (Cannot stack) | Up to 100" (254 cm) double-stacked |

I often explain to buyers that we are fighting "Humidity Fatigue" and logistics abuse. By over-engineering the corrugated structure to a 3.5x safety factor, we ensure that your brand stands tall while the competitor's display is leaning over in the aisle.

Conclusion

The difference between cardboard and corrugated isn't just terminology; it's the difference between a product that sells and a product that gets thrown in the trash compactor. Whether you need a sleek counter display or an industrial-strength pallet, getting the material specs wrong is an expensive mistake you don't want to make.

If you are unsure if your current design will survive the journey to Walmart or Costco, let's test it. I can provide a Free Structural 3D Rendering to visualize the strength, or ship you a Physical White Sample so you can crush-test it yourself before committing to a full order.

Discover the concept of structural memory and its significance in material selection for packaging. ↩

Learn why corrugated board is essential for structural integrity and stacking strength in packaging solutions. ↩

Understand the implications of using Recycled Testliner in packaging and its impact on durability. ↩

Explore the advantages of using High-Grade Virgin Kraft Liner for superior strength and durability in packaging. ↩

Discover strategies to elevate your packaging design to a premium level, attracting more customers. ↩

Explore the advantages of E-Flute in packaging for better print quality and structural integrity. ↩

Understanding the Tipping Point can help you design more effective retail displays that won't tip over. ↩

Learn how Mono-Material designs enhance sustainability and simplify recycling for consumers. ↩

Understanding the Edge Crush Test is crucial for ensuring your packaging meets industry standards and protects your products. ↩

Learn about Material Spec Deception to ensure you choose reliable packaging that truly meets your needs. ↩

Discover how Grain Direction affects the strength of your boxes and why it's vital for shipping success. ↩

Explore the advantages of High-Performance Kraft liners for durable and reliable packaging solutions. ↩

Understanding the Safety Factor of 3.5 is crucial for ensuring structural integrity in various environments, especially in packaging. ↩

Exploring ISTA 3A Testing Standards will provide insights into rigorous testing methods that ensure product safety during transport. ↩