You spend months developing a product, perfecting the packaging, and building a brand image. But if your retail display arrives with a "red" that looks more like a washed-out "orange," all that hard work loses its impact immediately.

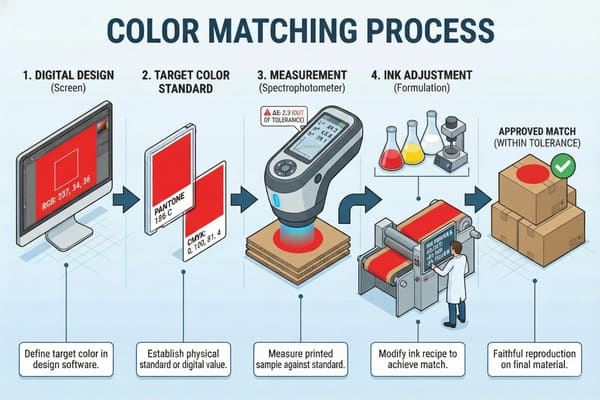

The color matching process is the systematic method of ensuring that a specific color produced in one medium, such as a digital design file on a computer screen, is faithfully reproduced in another medium, like ink on corrugated cardboard. It involves defining target color standards, measuring values with spectrophotometers, and adjusting ink formulations to achieve a visual match within a strict tolerance level.

Color consistency is the backbone of brand recognition in retail environments. When a customer walks into a store, they scan for familiar colors before they even read text.

What is the process of color matching?

Have you ever printed a photo at home and realized the colors looked nothing like they did on your phone screen? In professional packaging, we cannot afford those surprises because they kill consumer trust.

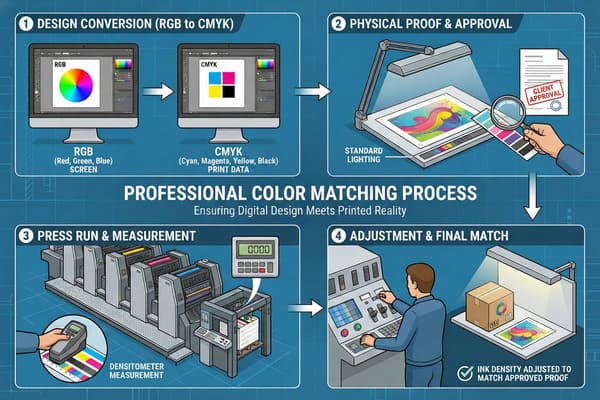

The professional process begins with converting digital RGB design files into CMYK printing data, followed by generating a physical proof for client approval. Printers then use densitometers to measure color bars during the press run, adjusting ink density levels to match the approved proof under standardized lighting conditions.

The Technical Workflow of Color Reproduction

Achieving the perfect color on cardboard displays is far more complex than just hitting "print." The journey starts with the artwork. Most designers work in RGB (Red, Green, Blue) because that is how monitors display light. However, printing presses use CMYK (Cyan, Magenta, Yellow, Black)1 ink. The first critical step is this conversion. If you just let software do it automatically, your vibrant blues might turn muddy. We have to manually adjust these profiles.

Once the file is ready, we move to the proofing stage. This is where many suppliers fail. They might send you a digital PDF proof, which is useless for color accuracy because every monitor is calibrated differently. A physical "wet proof" or a high-end digital contract proof is necessary. In my factory, we look at how the ink interacts with the paper. Corrugated cardboard is absorbent. If we put too much ink down, the dot gain increases, making images look darker or "muddy." If we use too little, the color looks weak.

We also have to consider the "whiteness" of the paper. We usually print on CCNB (Clay Coated News Back) paper for displays. This paper has a specific white point. If the paper is slightly yellow, it will shift every single color in your artwork toward yellow. We use a spectrophotometer2 to measure the spectral data of the color, not just what our eyes see. This device gives us a "fingerprint" of the color. During the mass production run, my press operators pull a sheet every few hundred copies to measure against this fingerprint. If the data drifts, they adjust the ink keys on the press immediately.

| Stage | Action Taken | Goal |

|---|---|---|

| Pre-Press | Convert RGB to CMYK3 | Ensure color gamut fits print capabilities. |

| Proofing | Generate GMG/Epson Proof | Create a physical reference target. |

| Make-Ready | Adjust Press Ink Keys | Align mechanical press output to the proof. |

| Production | Spectrophotometer Checks4 | Maintain consistency throughout the run. |

I know that waiting for a physical sample can feel like a delay, but I insist on it. We provide prototypes with free modifications until you are happy because I would rather lose time in the sample phase than ship you 1,000 displays that do not match your brand.

What is the color matching system?

Communicating color using words like "sky blue" or "leaf green" is impossible because everyone imagines something different. We need a universal language that does not rely on guesswork.

A color matching system is a standardized method of identifying and communicating colors, with the Pantone Matching System (PMS) being the global standard for printing. It uses a numbered index of specific ink formulas to ensure that a brand's specific shade remains consistent across different manufacturers and materials.

Navigating Pantone5 vs. CMYK6 in Packaging

In the world of cardboard displays, we operate with two main systems: Spot Color (Pantone/PMS) and Process Color (CMYK). Understanding the difference is vital for your budget and your branding. CMYK is like a painter mixing four primary colors to create an image. It is efficient and great for photographs. However, CMYK has a limited range. It struggles to produce very bright oranges, neon greens, or specific corporate deep blues.

This is where the Pantone system comes in. A Pantone color is a pre-mixed ink. It is not created by combining four colors on the press; it is mixed in a bucket before it even enters the machine. This guarantees 100% accuracy. For big brands like yours, your logo must be a specific Pantone color. If we print your logo in CMYK, small variations in the cyan or magenta plates can slightly shift the hue from one production run to the next. With a Pantone spot color, that variance is virtually eliminated.

However, adding Pantone colors adds cost. A standard printing press has four units for C-M-Y-K. If you want two specific Pantone colors for your branding, we need a six-color press. This requires more printing plates and more setup time. Furthermore, the material affects the system. Pantone has "C" (Coated) and "U" (Uncoated) codes. Since we print on coated paper for high-quality displays, you must select the "C" codes. If you pick a "U" code from your brand book, the final result on the glossy display will look completely different because the ink sits on top of the coating rather than sinking in.

| Feature | CMYK (Process)7 | Pantone (Spot)8 |

|---|---|---|

| Composition | Mix of 4 colors | Pre-mixed single ink |

| Accuracy | Good for images | Perfect for logos |

| Cost | Standard / Lower | Higher (requires extra plates) |

| Best For | Photos, gradients | Brand logos, solid backgrounds |

I always advise my clients to use a hybrid approach to save money while maintaining quality. We print your product images in CMYK to keep costs down, but we print your main logo header using one specific Pantone plate to ensure that critical brand recognition is perfect.

What is the 70 20 10 rule for colors?

Color matching is technical, but applying color is psychological. You can have perfect printing, but if the design balance is wrong, the customer will walk right past the display.

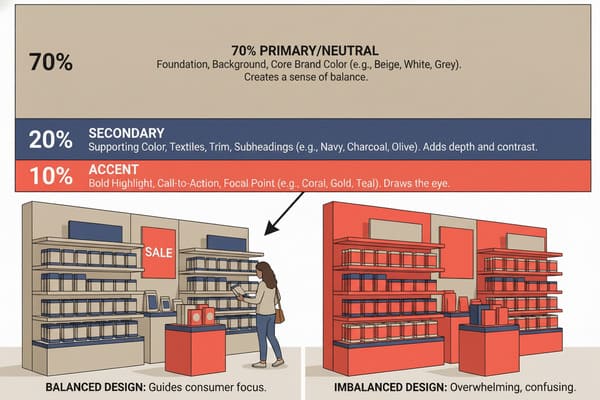

The 70-20-10 rule is a timeless design principle stating that 70% of the visual space should be a neutral or primary brand color, 20% should be a secondary supporting color, and 10% should be a bold accent color used to highlight the most important action or price.

Applying Ratio Psychology to Retail Displays

When we design a structure for a floor display, we are not just making a box; we are directing the consumer's eye. The retail environment is visually chaotic. If a display is covered in a rainbow of equal-strength colors, the human brain ignores it as "noise." The 70-20-10 rule9 helps us cut through that noise.

The 70% usually applies to the body of the display. This is your primary brand color or a neutral background (like white or black) that allows the products to stand out. It sets the mood but does not scream for attention. For example, in the hunting industry, this might be a camouflage pattern or a dark forest green. It creates the context.

The 20% is for the information hierarchy. This includes your sub-headlines, product benefit lists, or secondary graphics. It supports the main theme but provides contrast. Finally, the 10% is the most critical part: the Call to Action (CTA)10. This is where we put the price tag, the "New Arrival" burst, or the "Buy Now" text. We use a highly contrasting color here—like a bright yellow on a black background or a red on white. Because this color is used so sparingly, the eye is magnetically drawn to it. If you make the whole display bright red, the red "Sale" sign becomes invisible. By limiting the accent color to 10%, we force the customer to look exactly where we want them to look.

| Ratio | Purpose | Application in Display |

|---|---|---|

| 70% | Foundation11 | Base structure color, background patterns. |

| 20% | Information12 | Text, secondary graphics, product images. |

| 10% | Action | Prices, "New" badges, QR codes. |

We use this rule in my design department for every 3D rendering we present. I often see clients try to make the logo 50% of the design, but I gently guide them back to this rule to ensure the display actually sells the product, rather than just showing a logo.

What is the rule for color matching?

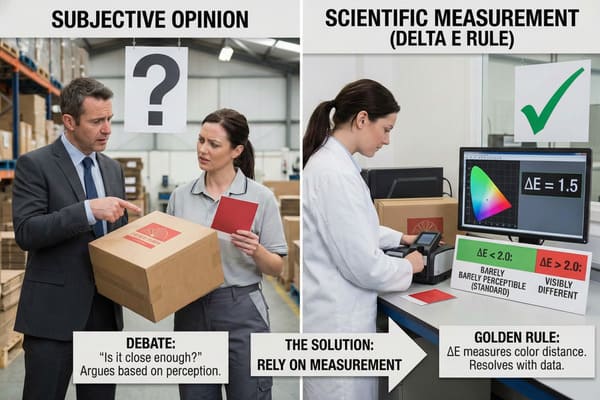

There is often a debate between a factory and a client about whether a color is "close enough." To avoid arguments, we rely on scientific measurement rather than subjective opinion.

The golden rule for color matching relies on Delta E (ΔE), a metric that measures the distance between two colors in a 3D color space. A ΔE of less than 2.0 is generally considered the standard for high-quality printing, as the difference is barely perceptible to the human eye.

Understanding Delta E13 and Lighting Standards

The biggest source of frustration in this industry is a phenomenon called "Metamerism14." This happens when your display looks perfect in my factory office but looks completely wrong under the fluorescent lights of a Walmart aisle. This occurs because different light sources have different spectral power distributions. A color that matches under natural daylight (D50) might separate under cool store lighting (TL84).

To follow the rule of color matching, we must agree on the light source first. The international standard for the graphic arts industry is D50 (5000 Kelvin). We use light booths that simulate this exact condition. When we measure the Delta E, we are calculating the mathematical difference between your approved proof and the sheet coming off the press.

• If the Delta E is under 1.0, it is a perfect match; even experts cannot tell the difference.

• If it is between 1.0 and 2.0, it is excellent and standard for high-end packaging.

• If it goes above 3.0, the human eye starts to see a real difference.

However, corrugated cardboard is a challenging substrate. It has "fluting" (the wavy inner layer) which can cause washboarding, creating shadows that affect color perception. We also have to account for the varnish. A glossy UV coating will darken the ink colors significantly compared to the raw print. Therefore, the rule is not just matching the ink, but matching the finished product after coating.

| Delta E Value | Perception | Suitability |

|---|---|---|

| < 1.0 | Invisible difference | High-end Art / Luxury15 |

| 1.0 – 2.0 | Slight difference | Standard for Displays16 |

| 2.0 – 3.0 | Noticeable | Acceptable for some transit boxes |

| > 3.0 | Obvious difference | Rejected |

I have equipped my production lines with advanced color management systems to keep Delta E low. We test the strength of the box, but we also test the strength of the color fidelity, ensuring your brand looks premium even in a harsh retail environment.

Conclusion

The color matching process is the bridge between your digital brand vision and the physical reality of the retail shelf. It requires a mix of precise technology, standardized systems like Pantone, and smart design psychology. By understanding these elements, we ensure your displays not only hold your product securely but also capture customer attention instantly.

Understanding CMYK is crucial for anyone involved in printing, as it directly impacts color accuracy and quality. ↩

Exploring how a spectrophotometer functions can enhance your knowledge of color accuracy in printing and design. ↩

Understanding CMYK is crucial for achieving accurate color reproduction in print, ensuring your designs look as intended. ↩

Exploring this topic reveals how precision tools enhance color consistency, vital for professional printing results. ↩

Explore the Pantone system to understand its importance in achieving color accuracy for branding and packaging. ↩

Learn about the CMYK model to grasp its efficiency in printing and its limitations compared to Pantone. ↩

Understanding CMYK is essential for anyone involved in graphic design or printing, as it affects color accuracy. ↩

Exploring Pantone will help you grasp how to achieve precise color matching for branding and design. ↩

Understanding the 70-20-10 rule can enhance your retail display strategies, making them more effective in capturing consumer attention. ↩

Exploring effective CTA strategies can significantly boost your sales by guiding customers towards making a purchase. ↩

Understanding the Foundation's role can enhance your design's effectiveness and visual appeal. ↩

Exploring the impact of Information color ratios can improve your design strategy and user engagement. ↩

Understanding Delta E is crucial for achieving accurate color reproduction in printing and design, ensuring your products look their best. ↩

Exploring Metamerism helps you grasp the challenges of color matching under different lighting, essential for quality control in production. ↩

Exploring color accuracy standards for high-end art ensures that you appreciate and maintain the quality of luxury items. ↩

Understanding the standard for displays can help you choose the right monitor for accurate color representation. ↩