I meet tight retail launch dates. I also fight color shifts and weak displays. Offset printing fixes these pains for me and for my clients fast.

Offset printing is a high-volume print method that transfers ink from a plate to a rubber blanket, then to paper or corrugated board. It delivers sharp text, stable Pantone colors, and low unit cost at scale. It fits brand displays, packaging, and catalogs.

I want you to get clear answers fast. I will show you what offset printing means, how it compares, why it works, and when to use it.

What is meant by offset printing?

I see many teams mix up print terms. This causes confusion and wasted time. I will make the meaning simple and practical.

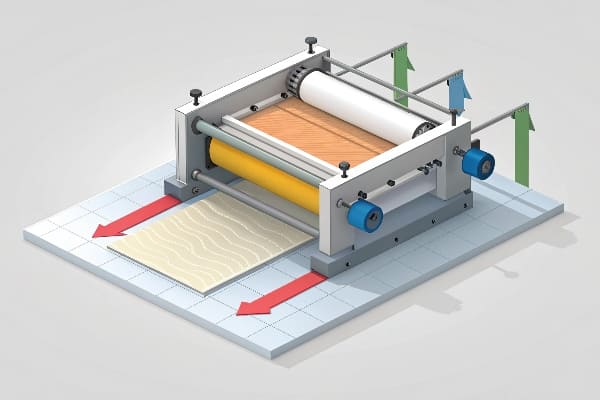

Offset printing uses metal plates to place ink onto a rubber blanket, then onto the substrate. The process keeps plates clean, holds dots stable, and gives consistent color on long runs. It suits paperboard and corrugated displays.

How the process works in plain steps

I use offset presses every week for POP jobs. I keep the steps simple and open.

1. Prepress plates: I output CMYK and spot color plates. I lock in trapping, overprint, and dielines.

2. Ink and water balance: The plate has image areas that accept ink and non-image areas that accept water. The balance keeps non-image parts clean.

3. Blanket transfer: The blanket grips the ink and presses it onto the board. The blanket protects fibers and reduces crush on corrugated flutes.

4. Drying and coating: I add water-based or UV coatings for scuff and gloss. I pick matte if a hunting brand needs low glare.

*5. Cutting and glue: I cut with dies, fold, and glue. I test load and transport before sign-off.

Where offset fits in my display work

I serve FMCG, beauty, and outdoor brands. The displays must look bold and clean. Offset hits this bar on most mid to large runs.

| Need | Why I choose offset | Typical Result |

|---|---|---|

| Sharp logos on trays | Plates hold fine lines | Crisp edges on small type |

| Stable brand colors | Pantone spots run true | Repeat orders match stores |

| Big volume | Setup cost spreads out | Lower unit price after breakeven |

| Corrugated top sheet | Blanket is gentle | Less flute crush, smooth face |

I run jobs for North America and Europe. These markets ask for quality and sustainability. Offset supports water-based inks1, FSC stocks2, and recyclable coatings. I also ship to APAC where growth is fast and timelines are short. Offset meets both speed and cost targets when I plan plates early and lock art fast.

What is the difference between offset printing and normal printing?

I hear "normal printing" in many calls. People often mean digital printing. I compare them in real terms that affect budget and time.

Offset uses plates and suits mid to large runs with lower unit cost and stable color. Digital uses no plates and suits small runs with fast setup and easy versioning. Offset wins on quality and scale; digital wins on speed and flexibility.

Side-by-side for display buyers

I lay out the points that push a team one way or the other. I base this on actual orders, including a hunting launch I ran for a U.S. client with strict shelf dates.

| Factor | Offset | Digital |

|---|---|---|

| Setup | Plates, make-ready time | Minimal setup |

| Unit cost | Low after breakeven | Flat, higher per unit |

| Run size | Best for 500+ units | Best for 1–500 units |

| Color | Strong solids, Pantone spots | Great CMYK, spots simulated |

| Materials | Paperboard, litho-lam corrugated | Most boards, direct-to-corr ok |

| Finishes | AQ, UV, soft-touch, metallic inks | Many coatings, some limits |

| Speed | Slower to start, fast once running | Fast start, steady speed |

| Variable data | Not native | Native and easy |

How I choose for Cardboard Displays

I sell to retail chains in the U.S., Canada, the U.K., and Australia. Buyers want on-time installs at Walmart, Costco, and outdoor dealers. If a client needs 5,000 floor displays3 with strict Pantone4, I go offset. The plates lock color and reduce drift across shifts. If a client needs 120 countertop sets to test two graphics, I go digital. The startup is simple, and the unit price is fine at low volume.

The display market grows in APAC and North America. Cost pressure is strong. Offset helps me hit target prices on repeat orders. Digital helps me win fast pilots. I plan both in one roadmap, so the pilot runs on digital and the rollout shifts to offset with the same artwork and dielines. This plan cuts risk and keeps brand control.

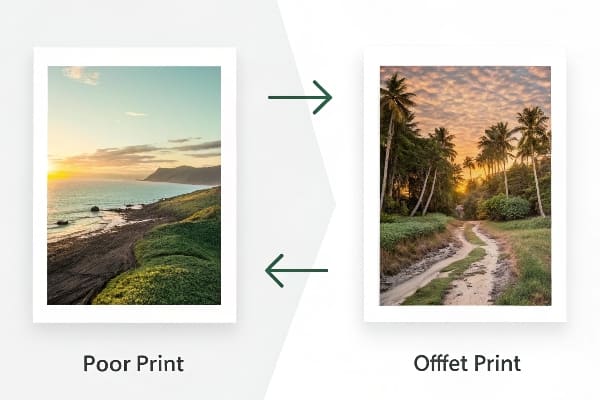

Is offset printing good quality?

Many buyers ask if offset will look premium enough. I judge quality by edges, solids, and repeatability. I also judge by how it survives shipping.

Offset delivers high image sharpness, rich solid areas, smooth gradients, and consistent color over long runs. Coatings add scuff resistance and gloss or matte control. Proper prepress and press checks keep results stable across reorders.

What "quality" means on a store floor

I break quality into clear parts. I test each part in my factory before I ship.

| Quality Aspect | What I look for | Offset Advantage |

|---|---|---|

| Text clarity | 6–8 pt legibility | Plates hold fine dots |

| Solid density | No banding or mottling | Inking units keep coverage even |

| Color match | Delta E within target | Pantone spots and curves |

| Coating | Scratch resistance | AQ/UV tuned to substrate |

| Board integrity | No flute crush | Rubber blanket transfer |

I lead QC on every mass run. I run drawdowns and a first-article check. I use spectro readings to lock CMYK and spot colors. I save standards for reorders. I also run transport tests5 and load tests6 because quality on press is not the same as quality after shipping. I have seen displays pass print checks but fail in transit. I changed flute grades, added edge protectors, and raised pass rates. My U.S. hunting client cares about rugged looks and low glare. I often pick matte AQ with spot gloss only on logos. The shelf looks clean, and the color stays true under store lights. This simple choice turns into fewer returns and faster reorders.

What does offset mean when printing?

Teams often ask what "offset" means beyond the machine. I explain the idea so buyers can plan budgets and files.

"Offset" means the press does not print directly from the plate to the paper. The ink first transfers to a rubber blanket, then to the sheet. This indirect step protects the sheet and stabilizes dots and color.

Practical meaning for cost, files, and timelines

I treat "offset" as a set of rules that shape art, schedules, and checks. I write them down for new buyers and engineers.

| Area | What "offset" changes | My guidance |

|---|---|---|

| Budget | Higher setup, lower unit cost at scale | Group SKUs, aim for breakeven |

| Artwork | Needs trapping, proper overprint, spot plates | Use vector logos and real Pantone |

| Photos | Needs good resolution and TAC control | Keep 300 dpi and safe ink limits |

| Substrates | Likes smooth top sheets and coated board | Use litho-lam for corrugated faces |

| Timelines | Needs plate output and make-ready | Lock art early; book press time |

I work with design teams in the U.S. who do 3D renders and print files. I receive dielines and layered PDFs. I preflight fonts, images, and overprint. I send a printed proof7 or press-OK photos on request. I plan plates once the proof is signed. This path saves time later. It also avoids color disputes. In Europe, buyers push for sustainable inks8 and FSC stock. Offset supports these needs with water-based coatings and recyclable liners. In APAC, growth is fast, and cost targets are tight. Offset hits unit price goals when I combine SKUs on a common form. I share this plan before we quote. This open talk builds trust and keeps launches on schedule.

Conclusion

Offset printing gives me stable color, sharp images, and good cost at scale. I use it for most display rollouts. I use digital for tests and fast changes.

Explore the advantages of water-based inks for sustainable printing practices and their impact on quality. ↩

Learn about FSC stocks and their role in promoting sustainable forestry and responsible sourcing in the printing industry. ↩

Explore this link to understand how large-scale floor displays can enhance visibility and sales in retail environments. ↩

Learn about the significance of strict Pantone in maintaining color consistency and brand integrity in printed materials. ↩

Understanding transport tests can help ensure your products maintain quality during shipping, reducing returns. ↩

Exploring load tests will provide insights into how to assess product durability, ensuring they withstand real-world conditions. ↩

Learn about printed proofs to ensure quality and accuracy in your print projects, preventing costly mistakes. ↩

Explore the advantages of sustainable inks to understand their impact on the environment and how they can enhance your printing projects. ↩