Choosing the right finish for your packaging or display can feel overwhelming when you have a specific brand image to maintain. You might worry that the wrong choice will make your high-quality products look cheap or make important text hard to read under store lights.

Matte lamination is a finishing process where a thin, transparent plastic film with a dull, non-reflective surface is bonded to printed paper or cardboard. It creates a soft, elegant texture that absorbs light rather than reflecting it, providing a sophisticated look while adding a protective layer against moisture and tearing.

Understanding the distinct properties of this finish helps you decide if it aligns with your product's retail environment and brand identity.

Which is better, glossy or matte lamination?

Many brands struggle to decide between high shine and subtle elegance, fearing their product will either look too flashy or too dull.

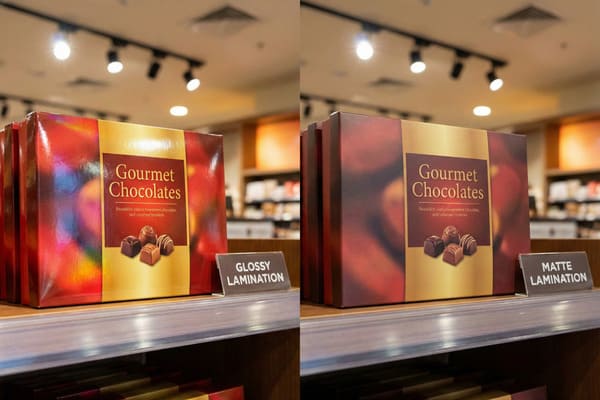

The better option depends entirely on your brand goals and the retail lighting environment. Glossy lamination offers high contrast and vibrant color pop, making it ideal for food and toys, while matte lamination provides a premium, non-glare finish that is better for reading text and conveying luxury.

The Strategic Impact of Visual Contrast and Lighting

Deciding between glossy and matte is not just about personal taste; it is a strategic decision that affects how customers perceive the value of your product in a crowded retail aisle. When we look at the physics of light in a retail setting, such as a Walmart or a specialized hunting store, the overhead fluorescent lighting is harsh. Glossy lamination reflects this light directly back at the shopper. If your display has a lot of instructional text or detailed product specs—which is common for technical items like crossbows or electronics—that glare can make the text unreadable from certain angles.

On the other hand, matte lamination1 diffuses light. It scatters the reflection, ensuring that your branding and messaging remain visible from every angle. This "soft" look is often associated with higher price points and modern luxury. However, there is a trade-off in color intensity. Matte films tend to slightly mute the vibrancy of ink. A bright red on a glossy finish will scream for attention, while that same red under a matte finish will look deep and rich but less aggressive.

From a durability standpoint, both laminates protect the underlying cardboard structure. However, they handle wear and tear differently. Glossy surfaces tend to show fingerprints and oily smudges very easily, which can make a display look messy if it is handled frequently by customers. Matte lamination resists fingerprints much better, but it can be more prone to showing visible scratches or scuffs if a sharp object drags across it during transport. This is why the quality of the film material used during the lamination process is critical to the final lifespan of the unit.

| Feature | Glossy Lamination | Matte Lamination |

|---|---|---|

| Light Reflection2 | High (creates glare) | Low (absorbs light) |

| Color Vibrancy | Enhances contrast and brightness | Mutes colors slightly, adds depth |

| Text Readability3 | Lower due to glare | Excellent, easy to read |

| Fingerprints | Highly visible | Barely visible |

| Scratch Visibility | Hides scratches well | Scratches can be more apparent |

| Perceived Value | Fun, energetic, budget-friendly | Premium, sophisticated, high-end |

I often see clients unsure about how the final colors will turn out on the cardboard. In my factory, I always recommend creating a physical proof before mass production. This allows you to put the sample under lights similar to your target retail store to see if the glare interferes with your design.

What does matte lamination look like?

It is difficult to visualize exactly how a non-reflective surface will appear on a large-scale floor display without holding it in your hands.

Matte lamination looks like a smooth, frosted surface that lacks any shine or sparkle, giving the print a muted and velvety appearance. It creates a "soft-touch" visual effect that flattens the image, making colors appear solid and uniform without the distraction of light bouncing off the surface.

Visual Characteristics and Tactile Experience

When you walk into a store, your eye is naturally drawn to light. However, too much reflection can be a distraction. Matte lamination looks "quiet." It does not shout for attention with sparkle; instead, it draws the consumer in with a sense of quality. The surface looks almost like a very smooth skin or a high-quality satin cloth rather than a piece of plastic. This visual effect is achieved because the surface of the film is not perfectly smooth at a microscopic level. It has a slight texture that breaks up light waves.

For brands that use dark colors—like deep blacks, forest greens, or navy blues—matte lamination4 transforms the look significantly. On a glossy display, black can look like a mirror. On a matte display, black looks like a void; it is incredibly deep and absorbs all attention. This is why many high-end tech and outdoor brands prefer it. It communicates a serious, professional tone.

Furthermore, the "look" is closely tied to the "feel." While we are discussing appearance, the tactile experience5 reinforces the visual one. When a customer brushes their hand against a matte display to pick up a product, the friction is higher than gloss. It feels like paper or fabric, which feels more natural. In the context of cardboard displays, this finish helps hide the corrugation lines (the flutes) that run through the board. Glossy finishes sometimes act like a magnifying glass, highlighting the ridges of the cardboard underneath. Matte finishes tend to mask these imperfections, making the display look like a solid construction rather than a folded box.

| Visual Aspect | Description |

|---|---|

| Surface Texture6 | Smooth, satin-like, non-reflective. |

| Color Depth | Colors appear flatter but richer and more consistent. |

| Imperfections | Hides cardboard fluting ridges better than gloss. |

| Lighting Interaction | Diffuses harsh store lighting; no "hot spots." |

| Brand Perception7 | Modern, natural, organic, luxury. |

I know that descriptions can only go so far. That is why my team provides high-resolution 3D renderings that simulate lighting effects during the design phase. We can adjust the "roughness" in the rendering software to show you exactly how the matte finish will interact with light before we even cut the first piece of cardboard.

What is a matte finish laminate?

You might wonder if the matte effect is just a spray coating or a chemical treatment applied to the paper.

A matte finish laminate is a physical sheet of BOPP (Biaxially Oriented Polypropylene) plastic film that has been treated to have a dull surface. This film is adhered to the printed paper sheet using heat and pressure to create a permanent bond before the paper is mounted onto the corrugated cardboard.

Material Composition and Manufacturing Process

It is important to understand that lamination is not a varnish. Varnish is a liquid coating printed onto the paper. Lamination is a separate material layer. In our industry, the most common material for this is BOPP film8. This material is stretched in two directions during its manufacture, which gives it incredible strength and clarity. For a matte finish, the surface of this film is chemically treated or mechanically roughened to scatter light.

The application process in my factory involves a thermal lamination machine9. We feed the printed paper sheets (which will later be glued to the cardboard) into the laminator. The machine feeds the matte plastic film from a large roll. Heated rollers melt a layer of adhesive on the back of the film and press it firmly onto the paper. The pressure is key here. If the pressure is too low, you get air bubbles (silvering). If the heat is too high, the paper curls.

This plastic layer does more than just look good. It acts as a structural reinforcement. Cardboard displays hold heavy products, and the stress points where the shelves fold can tear. The BOPP film has high tensile strength. It acts like a "skin" that holds the paper fibers together, preventing cracking at the fold lines. This is crucial for displays that need to last for weeks in a retail environment. The thickness of this film usually ranges from 12 to 15 microns. While thin, this layer provides a barrier against humidity, which is the enemy of cardboard.

| Specification | Details |

|---|---|

| Base Material | BOPP (Biaxially Oriented Polypropylene)10 |

| Standard Thickness | 12 microns to 15 microns |

| Application Method | Thermal bonding (Heat + Pressure)11 |

| Tensile Strength | High (prevents cracking at fold lines) |

| Barrier Properties | Water-resistant, oil-resistant |

I have seen suppliers try to cut costs by using inferior, thinner films or water-based varnishes and calling it "lamination." I ensure my production lines only use high-grade thermal films because I know that if the lamination peels at the corners, the whole display looks cheap. I personally check the bond strength on our sample runs to guarantee it will not delaminate during shipping.

Is matte laminate easy to clean?

Retail environments are dusty, and floor displays often get splashed by mopping, leading to concerns about keeping the display looking fresh.

Yes, matte laminate is relatively easy to clean because the plastic film creates a water-resistant barrier that protects the paper beneath. Dust and light dirt can be wiped away with a dry cloth, while sticky residue can be cleaned with a slightly damp cloth without damaging the print.

Maintenance and Longevity in Retail Environments

When a cardboard display sits on a retail floor for three or four months, it goes through a lot. Foot traffic kicks up dust, and cleaning crews often mop the floors around the display bases. Without lamination, a single splash of dirty mop water would ruin a cardboard stand immediately. Matte lamination provides a sealed plastic surface. This means moisture sits on top of the film rather than soaking into the paper fibers.

However, the texture of matte lamination12 presents a unique cleaning challenge13 compared to gloss. Because the surface is micro-textured to diffuse light, it has more "tooth" or grip. This means that while it repels water, it can sometimes hold onto dust or fine powders more stubbornly than a slick glossy surface. A simple dry dusting usually works, but for scuffs or dirt, you need to use a soft, non-abrasive cloth. You should never use harsh chemical cleaners or abrasive scrubbers, as these can polish the matte surface, creating an uneven shiny spot.

Another factor is the "fingerprint issue" mentioned earlier. While matte is great at hiding oils from fingers, if someone touches it with dirty or muddy hands, the dirt can get trapped in the texture. The good news is that because the film is plastic, you can use a damp cloth with a tiny drop of mild soap to wipe it down. This washability is a huge advantage over un-laminated or varnished displays, which cannot be cleaned at all once they are soiled.

| Contaminant | Cleaning Method for Matte Lamination14 | Effectiveness15 |

|---|---|---|

| Dust | Dry microfiber cloth | High |

| Liquid Splashes | Absorbent paper towel (dab, don't rub) | High (if quick) |

| Mud/Dirt | Damp cloth with mild soap | Medium/High |

| Ink/Marker | Isopropyl alcohol (test small area first) | Low/Medium |

| Scuff Marks | Soft white eraser | Medium |

I tell my clients that while we cannot control what happens in the store, we can build the display to survive it. I run resistance tests in my factory where we expose the laminated surfaces to moisture and friction. This ensures that when your display lands in a high-traffic area, it remains professional-looking for the duration of your campaign.

Conclusion

Matte lamination offers a sophisticated, non-glare finish that enhances readability and perceived quality, making it an excellent choice for premium brands. While it may mute colors slightly compared to gloss, its elegant texture and ability to hide fingerprints make it a favorite for high-end retail displays. By understanding the functional and aesthetic differences, you can select the finish that best elevates your product presentation.

Explore the advantages of matte lamination to enhance your retail displays and improve customer perception. ↩

Understanding light reflection can help you choose the right lamination for your project, enhancing its visual appeal. ↩

Exploring this topic will guide you in selecting the best lamination for clear and effective communication in your materials. ↩

Explore the advantages of matte lamination to enhance your product's visual appeal and tactile experience. ↩

Understanding tactile experience can help you design products that resonate better with consumers, improving engagement and sales. ↩

Understanding surface texture can enhance product appeal and user experience. ↩

Exploring brand perception can help businesses align their marketing strategies effectively. ↩

Explore this link to understand the properties and benefits of BOPP film in various applications, enhancing your knowledge of lamination. ↩

Discover the workings of a thermal lamination machine to appreciate its role in producing high-quality laminated products. ↩

Explore the advantages of BOPP in packaging, including its durability and versatility, to enhance your understanding of material choices. ↩

Learn about thermal bonding techniques to improve your manufacturing processes and product quality. ↩

Explore the advantages of matte lamination, including its durability and ease of cleaning, to enhance your retail display strategy. ↩

Learn effective cleaning techniques for matte laminated surfaces to maintain their appearance and longevity in retail environments. ↩

Discover effective techniques to maintain your matte lamination and enhance its longevity. ↩

Learn about the effectiveness of various cleaning methods to choose the best one for your needs. ↩