Walking into a busy retail store, you only have seconds to grab a customer's attention. If your cardboard display looks dull or cheap, your product gets ignored. The finish you choose for your packaging makes the difference between a sale and a missed opportunity.

Gloss lamination is a finishing process where a thin plastic film is bonded to the surface of cardstock or cardboard. This coating reflects light, creating a shiny, vibrant appearance that enhances color saturation and protects the material from moisture, scratches, and dust. It is widely used in retail displays to make graphics pop.

Many brands struggle to decide if this shiny finish is right for their specific product line. Let's break down exactly how it works and compare it to other options to help you make the best choice for your retail rollout.

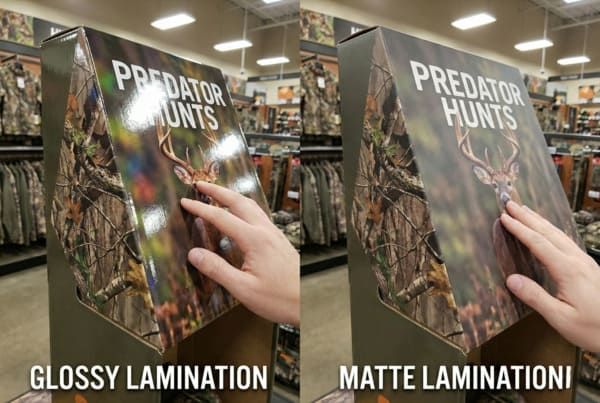

Which is better, glossy or matte lamination?

You have designed a killer graphic for your hunting gear display. Now, you face a common dilemma: do you want it to shine brightly or look understated and elegant?

The choice depends entirely on your brand goals and retail environment. Gloss lamination is better for high-contrast graphics and attracting attention in dim stores, as it enhances color vibrancy. Matte lamination is better for luxury items and text-heavy designs, as it offers a non-glare, sophisticated, and soft-touch surface.

Visual Impact and Durability Analysis

When we compare these two finishes, we must look beyond just personal preference. We need to analyze how they perform in the harsh environment of a retail chain like Walmart or Costco. Gloss lamination1 is the workhorse of the display industry. Technically, it reflects light in a specular direction, which means it has a high shine. This reflection increases the perceived contrast of the printed image. Blacks look deeper, and reds look more intense. If you are selling outdoor gear or action-oriented products, this vibrancy grabs the eye from down the aisle.

However, durability is a massive factor for products that ship from Shenzhen to the US. Gloss lamination is naturally more resistant to moisture and dust. If a floor mop hits the bottom of your display, gloss wipes clean. Matte lamination2, while beautiful, has a "soft" texture that can be prone to scuffing. During transport, vibrations in the container can cause matte surfaces to rub against each other, leaving shiny marks or scratches. To prevent this with matte, we often have to add an expensive anti-scratch coating. Gloss hides these minor transport abrasions much better because the high reflectivity masks surface imperfections. Furthermore, under the intense fluorescent lighting of big-box stores, gloss can create glare that makes text hard to read. If your display has a lot of instructional text, the glare from gloss might be a hindrance, whereas matte absorbs that light and improves readability.

| Feature | Gloss Lamination | Matte Lamination |

|---|---|---|

| Light Reflection3 | High (Shiny/Glare) | Low (Dull/Non-glare) |

| Color Appearance4 | Vibrant, High Contrast | Muted, Sophisticated |

| Scratch Visibility | Low (Hides marks well) | High (Shows scuffs easily) |

| Protection | High moisture resistance | Moderate (Can retain stains) |

| Cost | Lower | Higher (10-20% more) |

I always advise my clients to test their prototypes under actual store lighting. At PopDisplay, we provide physical proofs with both finishes so you can see the color shift before mass production. We also run scuff tests to ensure the laminate holds up during transport.

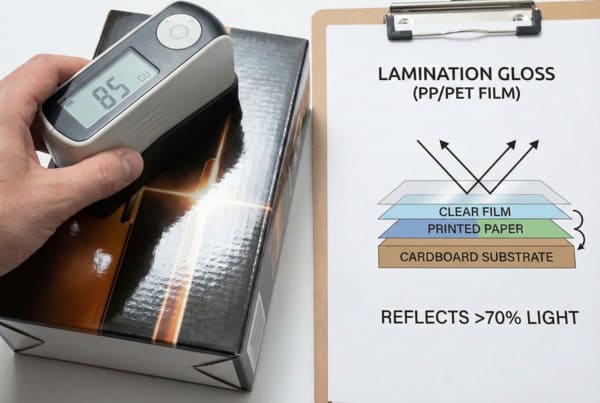

What is lamination gloss?

Understanding the technical side of printing helps you spot quality issues before they happen. It is not just about making things shiny; it is about protection and structure.

Lamination gloss refers to the specific measurement of light reflectivity on the surface of the laminate film. High-gloss films typically reflect over 70% of light, creating a glass-like finish. It is achieved by applying a clear polypropylene (PP) or polyester (PET) layer over the printed paper using heat and pressure.

Technical Specifications and Material Composition

To understand what you are buying, you need to know what happens on the factory floor. Lamination gloss is not a spray; it is a physical film. In the cardboard display industry, we primarily use a process called "wet lamination" or "thermal lamination." For high-volume orders, we use Polypropylene (PP) film5. It is flexible, clear, and bonds well to the clay-coated back (CCB) paper that we eventually mount onto the corrugated cardboard. The "gloss" level is measured in Gloss Units (GU). A standard high-gloss film for a retail display usually measures between 70 and 90 GU when measured at a 60-degree angle.

One critical issue buyers face is delamination6, where the film peels off the paper. This often happens if the "surface energy" (dyne level) of the printed paper is too low, or if the glue temperature during application was inconsistent. If you see bubbles or peeling on your samples, it means the bond failed. Another factor is the thickness of the film, typically measured in microns. For floor displays, we usually use 25 to 30-micron films. Thinner films save money but may curl or crack at the fold lines when the display is assembled. Thicker films provide better structural support but cost more. The gloss film also acts as a barrier. It prevents the paper from cracking when we die-cut the complex shapes of your display. Without this laminate, the raw paper fibers would break at every fold, making the display look worn out before it even hits the shop floor.

| Material Type | Clarity | Flexibility | Cost | Common Use |

|---|---|---|---|---|

| Polypropylene (PP)7 | High | Excellent | Low | Standard Retail Displays |

| Polyester (PET)8 | Very High | Rigid | Medium | rigid Boxes/High-end |

| Acetate | Medium | Good | High | Biodegradable options |

At my factory, we monitor the temperature rollers strictly to prevent peeling. I use high-grade PP film that balances flexibility with shine, ensuring your displays don't crack when folded during assembly.

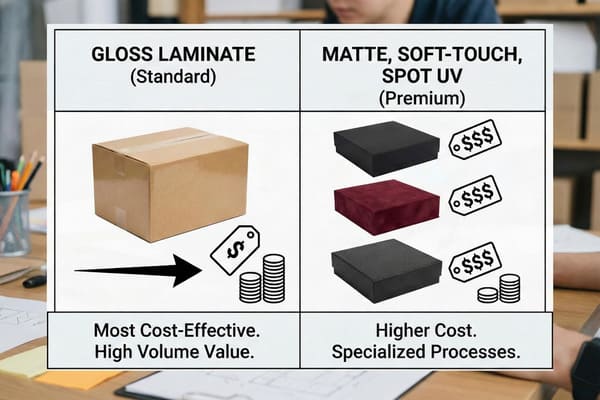

Is gloss laminate more expensive?

Budget is always a factor when launching a new product across the US and Canada. You need to know if adding a premium shine will eat into your profit margins.

Generally, gloss laminate is the most cost-effective finishing option available. It is standard in the industry and typically costs less than matte lamination, soft-touch coatings, or spot UV treatments. Because it is produced in higher volumes and requires less specialized handling than matte films, it offers excellent value for budget-conscious campaigns.

Cost Breakdown and ROI Calculation

When we look at the cost structure of manufacturing a cardboard display, the finish is a small but significant percentage. Gloss lamination is the industry standard baseline. Because film manufacturers produce glossy PP film in massive quantities, the raw material cost is significantly lower than matte or specialty films. Matte films require an additional chemical treatment or mechanical texturing during their manufacturing process to scatter light, which drives up the price.

From a production standpoint, running gloss lamination9 is also faster. Matte films can be more sensitive to heat and pressure variations, requiring slower machine speeds to ensure a perfect finish without "silvering" (tiny air bubbles trapped under the film). Slower machine speeds mean higher labor and electricity costs for the factory, which we have to pass on to the buyer. Additionally, gloss lamination has a lower reject rate. Scratches on matte film during the production process are very visible, leading to more wasted sheets. Gloss hides these minor imperfections, resulting in a higher yield. For a large order of 5,000 floor displays, choosing gloss over matte could save you thousands of dollars. However, you must weigh this against the Return on Investment (ROI)10. If your competitor uses a premium soft-touch matte and you use a standard gloss, your product might look cheaper in comparison. But strictly speaking of manufacturing costs, gloss is the winner for economy.

| Finish Type | Relative Cost Index | Production Speed | Scratch Reject Rate |

|---|---|---|---|

| Gloss Lamination11 | 1.0 (Baseline) | Fast | Low |

| Matte Lamination12 | 1.15 – 1.25 | Medium | High |

| Soft Touch | 1.50 – 1.80 | Slow | Very High |

| Varnish (No Lam) | 0.80 | Very Fast | N/A (Low protection) |

I know that keeping unit costs down is vital for your resale margins. We optimize our film purchasing to keep gloss lamination prices low without sacrificing the bond strength. I provide transparent quotes so you can see exactly where your money goes.

What is a gloss lamination sticker?

Sometimes you do not need a full display; you just need to update existing branding or add a promotional badge. Stickers are the quick fix for these situations.

A gloss lamination sticker is an adhesive label topped with a clear, shiny plastic layer. This layer protects the ink from fading, water, and oils while making the colors appear sharper. They are commonly used for branding updates, correcting information on existing packaging, or adding promotional "New" badges to retail displays.

Application and Adhesive Performance

In the world of retail displays, stickers serve a strategic purpose. We often call them "patches" or "overlays." A gloss lamination sticker consists of three layers: the backing paper, the printed vinyl or paper substrate, and the top gloss laminate layer. The gloss laminate13 here is crucial for outdoor or high-traffic performance. For a brand like yours that deals with hunting gear, products might be displayed in semi-outdoor environments or hardware stores where humidity varies. A plain paper sticker would absorb moisture, wrinkle, and peel off. The gloss laminate acts as a shield, making the sticker waterproof and UV resistant.

This is vital for "correction" stickers. Let's say you printed 10,000 boxes but realized the barcode is wrong. Reprinting the boxes is a financial disaster. A high-opacity gloss sticker can cover the error seamlessly. The gloss finish matches the gloss of the box, making the fix invisible to the consumer. The adhesive strength is also a major technical detail. For cardboard displays, which have a fibrous and uneven surface, we need a "permanent" rubber-based adhesive rather than a water-based acrylic one. The rubber flows better into the corrugated fibers. If the adhesive is too weak, the sticker edges will lift (flagging) after a few weeks in a dry retail store. The gloss laminate adds tension to the sticker, so the adhesive must be strong enough to counteract that tension and keep the sticker flat.

| Sticker Component | Function | Critical Factor for Displays |

|---|---|---|

| Top Coat | Gloss Laminate | UV & Moisture Protection14 |

| Face Stock | Vinyl or Paper | Opacity (must cover errors) |

| Adhesive | Permanent Glue | High Tack for uneven cardboard15 |

| Liner | Release Paper | Ease of peeling for assembly |

We often use these for clients who need last-minute changes to their artwork. I ensure the adhesive is strong enough to stick to corrugated board without lifting, even in humid warehouse conditions.

Conclusion

Gloss lamination is a powerful tool for creating durable, high-impact retail displays that fit a tight budget. It protects your branding and ensures your colors shine in crowded stores. I can help you decide if this finish matches your specific product goals.

Explore the advantages of Gloss lamination for retail displays, including its durability and visual appeal, crucial for attracting customers. ↩

Discover how Matte lamination enhances product displays by improving readability and aesthetics, making it a popular choice for certain products. ↩

Understanding light reflection can help you choose the right lamination for your project. ↩

Exploring color appearance differences can guide you in selecting the best finish for your design. ↩

Explore the advantages of Polypropylene (PP) film to understand its role in enhancing packaging durability and clarity. ↩

Learn about delamination causes to ensure your products maintain quality and avoid costly failures. ↩

Explore the advantages of Polypropylene (PP) in retail displays, including its cost-effectiveness and durability. ↩

Learn why Polyester (PET) is favored for high-end packaging due to its clarity and rigidity. ↩

Explore the advantages of gloss lamination to understand its cost-effectiveness and production efficiency in manufacturing. ↩

Learn how to effectively calculate ROI to make informed decisions about manufacturing investments and cost management. ↩

Explore the advantages of Gloss Lamination to enhance your printing projects with a professional finish. ↩

Discover how Matte Lamination can provide a unique aesthetic and durability for your printed materials. ↩

Understanding gloss laminate can enhance your sticker's durability and effectiveness in various environments. ↩

Explore this link to learn effective techniques for protecting your stickers from UV damage and moisture. ↩

Discover why High Tack adhesives are crucial for ensuring stickers adhere properly to uneven surfaces. ↩