Nothing kills a product launch faster than a display that feels like rough, unfinished sandpaper. If your packaging looks dull or smudges when a customer picks it up, the sale is lost before they even look at the price.

Aqueous coating is a water-based clear varnish applied to printed surfaces during the lithographic printing process to seal wet ink and enhance visual appeal. It dries instantly via hot air to provide scuff resistance and a range of finishes from matte to high-gloss while remaining 100% recyclable.

What does aqueous coating mean?

Think of your cardboard display like a car without wax; the paint might be there, but it lacks depth and protection. Without a proper seal, ink rubs off on customers'hands, which is a disaster for brand reputation.

Aqueous coating means a water-based clear varnish applied to printed surfaces during the lithographic printing process to seal wet ink and enhance visual appeal. It dries instantly via hot air to provide scuff resistance and a range of finishes from matte to high-gloss while remaining 100% recyclable.

The Mechanics of Water-Based Protection

Let's get technical about what happens on my factory floor because understanding the mechanics will save you from a disaster. When we run a job on our Heidelberg Speedmaster litho presses, the paper travels at incredible speeds, sometimes hitting 15,000 sheets per hour. If we just sprayed wet ink on the paper and immediately stacked it, the massive weight of the pile would cause the wet ink to transfer to the back of the sheet sitting above it. We call this "offsetting" or "ghosting," and it absolutely ruins the entire batch. I learned this the hard way years ago with a rush order for a toy brand where we skipped the coating to save pennies. The result was a rejected container because the red ink smeared onto the white parts of the design, and it was a total nightmare to reprint.

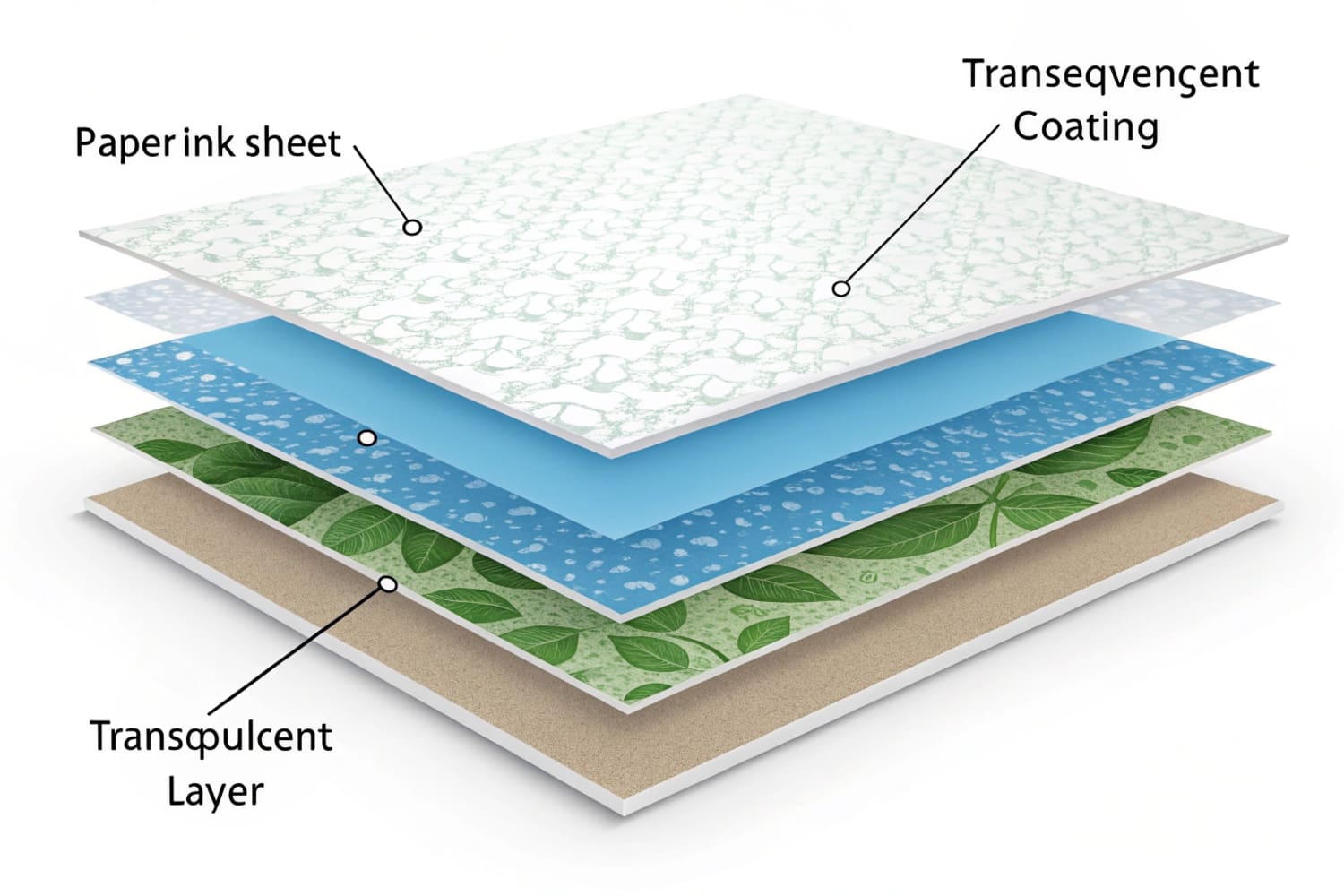

Now, we apply Aqueous (AQ) coating1 inline as a standard operating procedure. This means the coating is applied by the very last unit of the printing press tower. The mixture is roughly 60% to 70% water combined with acrylic polymers. As soon as it hits the paper, the sheet passes under hot air and Infrared (IR) dryers. The water evaporates instantly, leaving a thin, flexible polymer film. This isn't just about adding shine; it is fundamentally about "Rub Resistance2." In the harsh US retail environment, a package might be touched by 50 different people before it is finally purchased. Raw ink wears off under that friction, but AQ coating locks the pigment in, preventing that cheap, worn-out look.

Furthermore, because it is water-based, it is generally non-toxic. For my clients selling baby products or food, we use specific AQ formulations that meet the Baby Safe Ink Standard3, ensuring no heavy metals or toxic solvents leach out if a child mouths the packaging. It also helps mitigate the "Washboard Effect4" on standard B-flute by providing a smoother light reflection surface, though it won't hide the flutes completely like lamination would. We treat AQ coating as the default factory setting for quality assurance. Unless you explicitly ask me to remove it to save a fraction of a penny, which I will advise against, every single litho-printed display leaving my facility gets a protective coat of AQ. It is the cheapest insurance policy for your print quality.

| Feature | Raw Ink (No Coating) | Aqueous (AQ) Coating |

|---|---|---|

| Drying Time | Hours to Days (Oxidation) | Instant (Evaporation) |

| Rub Resistance | Low (Smudges easily) | High (Seals ink) |

| Yellowing | Prone to yellowing over time | Non-yellowing |

| Eco-Profile | Standard | 100% Repulpable/Recyclable |

| Cost | Baseline | Very Low (Standard inclusion) |

I treat AQ coating as the "Standard Factory Setting." Unless you explicitly ask me to remove it to save a fraction of a penny, which I will advise against, every single litho-printed display leaving my facility gets a protective coat of AQ. It is the cheapest insurance policy for your print quality.

What is the difference between aqueous and non aqueous film coating?

Clients often confuse "shiny" with "laminated," but they are chemically opposing worlds. Choosing the wrong one can either cause your display to peel in a hot truck or get rejected by a recycling facility.

The difference between aqueous and non aqueous film coating lies in the application method, where aqueous is a liquid varnish absorbed into paper fibers. In contrast, non-aqueous film coating involves laminating a solid plastic layer, such as polypropylene, onto the surface using adhesive.

Liquid Absorption vs. Plastic Lamination

Here is the messy reality of manufacturing that brochures don't tell you: Cardboard breathes. It expands when the humidity is high and shrinks in dry heat. Aqueous coating5 breathes with the paper because it is a liquid that partially soaks into the fibers, roughly 0.0005 inches (12–18 microns) deep, before drying. This makes it flexible. If you ship a display from humid Shenzhen to dry Las Vegas, the AQ coating flexes naturally with the substrate. It essentially becomes part of the paper, moving as the fibers move, which prevents any structural separation during transit across different climate zones.

Non-aqueous film coating, often called PP Lamination, is a solid sheet of Polypropylene plastic glued to the top of the paper. It looks amazing, offering a super glossy or Anti-Scuff Matte finish that feels like luxury. However, it creates a "bi-material" sandwich that fights against itself. The problem is delamination. I once had a client insist on thick gloss lamination for a pallet display going to a hot distribution center in Arizona. The extreme heat melted the glue slightly, and because the cardboard shrank in the dry air while the plastic film stayed the same size, the film bubbled and peeled off like sunburned skin. It looked absolutely terrible, and the retailer almost rejected the load.

Also, there is the massive issue of the Recycling Mandate6. US retailers like Walmart and Costco are pushing hard for "Mono-Material" packaging to meet sustainability goals. Aqueous coating allows the recycling plant to simply throw the box in the pulper, where the water breaks down the varnish easily, making it Curbside Recyclable7. Film lamination, however, clogs the recycling machinery because the plastic film must be mechanically separated from the paper fibers. Since most facilities don't do this, it often ends up in the landfill. If you need the display to survive a wet floor mop, we might use a special Mop Guard varnish on the bottom, but generally, AQ is the eco-friendly winner.

| Feature | Aqueous Coating (AQ) | Film Lamination8 (PP/PET) |

|---|---|---|

| Structure | Liquid Varnish (Absorbed) | Solid Plastic Sheet (Glued) |

| Recyclability | 100% Repulpable (Easy) | Difficult (Mixed Material) |

| Durability | Moderate (Scuff Resistant) | Extreme (Tear/Water Resistant) |

| Flexibility | High (Moves with paper) | Rigid (Can delaminate) |

| Cost | Low (Integrated process) | High (Separate process) |

If you are selling organic food or targeting Gen Z, do not use Film Lamination. Use Gloss AQ. It gives you 80% of the shine but allows you to print "100% Recyclable" on the box honestly. That marketing claim is worth more than the extra gloss.

What is the difference between PLA and aqueous coating?

Brands often get tricked by "Biodegradable" buzzwords and end up buying expensive materials that actually hurt their recycling scorecard. Just because it comes from corn doesn't mean it belongs in a cardboard baler.

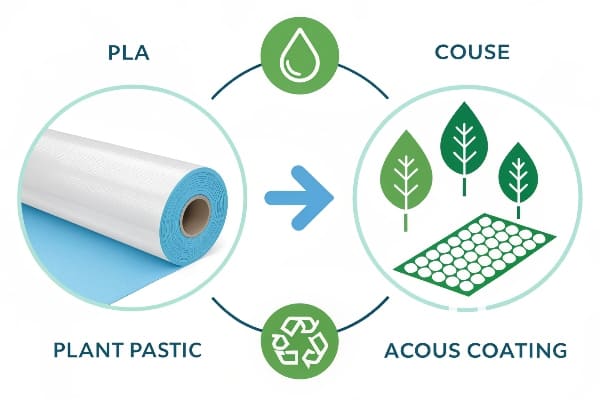

The difference between PLA and aqueous coating centers on end-of-life processing, as PLA is a bioplastic requiring industrial composting to degrade. Conversely, aqueous coating is a water-soluble varnish that dissolves in standard paper recycling pulpers, allowing packaging to be processed without contaminating the stream.

The "Green" Trap: Compostable vs. Recyclable

This is a conversation I have weekly with US buyers who want to be sustainable but get confused by the terminology. They ask if we can use PLA coating so they can market the display as biodegradable. My answer is always a question back: Do you want your customers to compost it or recycle it? PLA, or Polylactic Acid, acts like a plastic. It creates a decent barrier against grease and water, which is great for coffee cups, but in the world of Cardboard Displays, our goal is OCC (Old Corrugated Containers) recycling. This refers to the standard Blue Bin system found at the back of every Walmart and Target.

If you put a PLA-coated display into the standard paper recycling stream, the PLA does not dissolve like AQ does. Instead, it creates "stickies" in the paper pulp, which are gummy residues that ruin the recycled paper batch. PLA only degrades in Industrial Composting9 Facilities that maintain high heat and specific bacteria levels. Most US municipalities do not have these facilities readily available for consumer packaging. Aqueous Coating10, on the other hand, is water-soluble. When the display is pulped, the AQ dissolves harmlessly into the water, leaving the fiber clean for reuse. This ensures that the material actually gets recycled rather than being filtered out as trash at the facility.

Furthermore, we are seeing strict regulations coming from states like California and New York regarding PFAS11, also known as Forever Chemicals. Older grease-resistant coatings often contained PFAS. Modern Aqueous coatings are available in verified PFAS-Free formulas. I now strictly verify that our AQ varnishes are free from fluorinated chemicals to protect my clients from state-level lawsuits, whereas PLA supply chains can sometimes be murkier regarding additives. Unless you are selling a product that leaks grease directly onto the display, sticking to Aqueous Coating aligns with the existing US recycling infrastructure.

| Feature | Aqueous Coating | PLA (Polylactic Acid) Coating12 |

|---|---|---|

| Base Material | Water & Acrylic Polymers | Corn Starch / Sugarcane |

| End of Life | Standard Paper Recycling | Industrial Composting |

| Recycling Stream | Accepted in Blue Bins | Contaminant in Paper Stream |

| Heat Resistance | High | Low (Deforms > 105°F / 40°C) |

| Primary Use | Retail Displays / Folding Cartons | Food Containers / Coffee Cups |

Unless you are selling a product that leaks grease or water directly onto the display, stick to Aqueous Coating. It aligns with the existing US recycling infrastructure (OCC), ensuring your display doesn't become a contaminant.

What is the difference between aqueous and UV coating?

You want your logo to pop off the shelf, but picking the wrong shiny finish can lead to ugly cracks that make your brand look cheap. It comes down to flexibility versus hardness.

The difference between aqueous and UV coating is defined by their curing mechanism and flexibility, with aqueous utilizing hot air to create a breathable, flexible seal. UV coating uses ultraviolet light to cure instantly into an extremely hard, glass-like finish that is prone to cracking when folded.

The "Cracking" Nightmare and Registration Drift13

UV Coating14 is essentially liquid glass. It is cured instantly by high-intensity UV lamps on the press. Visually, it looks spectacular because it provides a wet, deep, and incredibly shiny finish that AQ cannot match. But here is the physical limitation that designers often forget: Cardboard displays need to fold. When you fold a piece of cardboard coated in thick UV, the board bends, but the UV coating is too hard to stretch. It snaps. You get a jagged white crack along the fold line, known in the industry as "crazing." I have had to scrap entire production runs because the designer put heavy UV over a fold line, and the result looked like broken glass on the edges, effectively ruining the premium look the client paid for.

Aqueous Coating15 is softer and chemically distinct. It bends with the fold. It doesn't have the same "wet look" intensity as UV, but it stays intact during assembly. Often, clients want the best of both worlds, so they ask for Spot UV just on the logo. But this introduces another factory headache known as Registration Drift. Since paper stretches during the printing process, if we try to register Spot UV perfectly over a logo on a large corrugated sheet, the shiny spot might miss the logo by 1mm. My fix for this is to use High-Viscosity Screen Printing with a trapping allowance, or simply use a high-gloss AQ coating for the whole box which is cheaper and safer.

Also, consider the Litho-Cracking Phenomenon16 caused by climate differences. If you are shipping to a dry climate like Colorado or Nevada, the paper dries out and becomes brittle. UV coating makes this worse because it seals the surface too tightly. AQ coating helps retain a tiny bit of moisture balance in the fibers, keeping the display's structural integrity intact. I always advise against UV for structural parts; save it for flat header cards that don't need to be folded. It is simply not worth the risk of your display looking damaged before it even holds a product.

| Feature | Aqueous Coating | UV Coating |

|---|---|---|

| Curing Method | Hot Air / IR | Ultraviolet Light |

| Flexibility | High (Good for folds) | Low (Cracks on folds) |

| Gloss Level | 40–80 Gloss Units | 90+ Gloss Units (Wet Look) |

| Chemical Odor | Low / None | Distinct Chemical Smell |

| Cost | Low | Moderate to High |

My advice? Use AQ for the overall protection and sheen. Only use UV if you have a flat, non-folding header card that needs to scream "Luxury." For the structural body, UV is a risk I don't recommend taking.

Conclusion

Understanding these coatings isn't just about aesthetics; it's about making sure your display survives the journey from China to a US retail floor without peeling, cracking, or getting rejected by recyclers.

If you are unsure which finish works for your specific artwork, would you like me to send you a Free Physical White Sample with different coating options so you can feel the difference yourself?

Explore this link to understand how AQ coating enhances print quality and protects against wear. ↩

Learn about Rub Resistance and its importance in maintaining the integrity of printed materials. ↩

Discover the significance of the Baby Safe Ink Standard for ensuring safety in packaging for children. ↩

Find out how the Washboard Effect impacts packaging design and how to mitigate it. ↩

Explore the advantages of Aqueous coating for sustainable packaging solutions and its impact on recyclability. ↩

Understand the Recycling Mandate and how it influences packaging choices for sustainability. ↩

Discover the meaning of Curbside Recyclable and its importance in eco-friendly packaging. ↩

Learn about Film Lamination's durability and potential issues like delamination in packaging. ↩

Find out how Industrial Composting operates and its role in managing biodegradable materials effectively. ↩

Explore this link to understand how Aqueous Coating enhances recycling processes and supports sustainability. ↩

Discover the risks associated with PFAS in packaging and how to choose safer alternatives for your products. ↩

Learn about the environmental implications of PLA Coating and why it may not be the best choice for recycling. ↩

Discover effective strategies to prevent Registration Drift and ensure accurate printing results. ↩

Explore the pros and cons of UV Coating to understand its impact on print quality and durability. ↩

Learn how Aqueous Coating offers flexibility and moisture retention, making it a safer choice for certain applications. ↩

Understand the factors leading to Litho-Cracking and how to mitigate its effects on printed products. ↩