I often see great products hurt by weak packaging. Teams rush, printers guess, and costs rise. I fix this with clear dielines. I use them to align design, structure, and production.

A dieline is a precise 2D blueprint that shows where packaging will be cut, creased, perforated, glued, and printed; it aligns designers, engineers, and printers so artwork fits the final 3D shape with safe margins and error-free production.

When you know what a dieline is, the next questions come fast. I answer the common ones here, with simple steps you can use today.

What is a dieline in packaging?

Many teams call everything a "template." I do not. I keep the word "dieline" for production. This helps buyers, printers, and my shop speak the same language.

A packaging dieline is the flat technical outline of a box or display that defines cut paths, fold scores, bleed, safety, glue areas, and orientation so design and manufacturing match exactly.

What a complete dieline1 must include

A dieline is not a sketch. It is a contract between design and print. I put each instruction on its own layer. I lock units and origin. I add notes that even a 3 a.m. shift can follow.

| Element | Layer name | Line style | Purpose | Typical color |

|---|---|---|---|---|

| Knife/Die cut | CUT | Solid | Final edge of the piece | Red |

| Crease/Score | SCORE | Dashed | Fold locations | Blue |

| Perforation | PERF | Dot–dash | Tear or bend lines | Green |

| Bleed2 | BLEED | Outline/frame | Extra ink beyond trim (usually 3–5 mm) | Magenta |

| Safety/Live area | SAFE | Outline/frame | Keep text/logos inside to avoid trimming | Cyan |

| Glue/No-print zones | GLUE / NO-PRINT | Solid fill | Adhesive panels or areas without ink | Yellow |

| Registration & notes | REG / NOTES | Symbols/Text | Printer marks, grain direction, assembly | Black |

I add panel names, arrows for "TOP/FRONT," and a 1:1 scale note. For corrugated, I mark flute direction, ECT/BF, and tuck or lock style. This avoids crushed edges and skewed artwork. In our PopDisplay factory, these basics cut remake rates and keep schedules tight for retail launches.

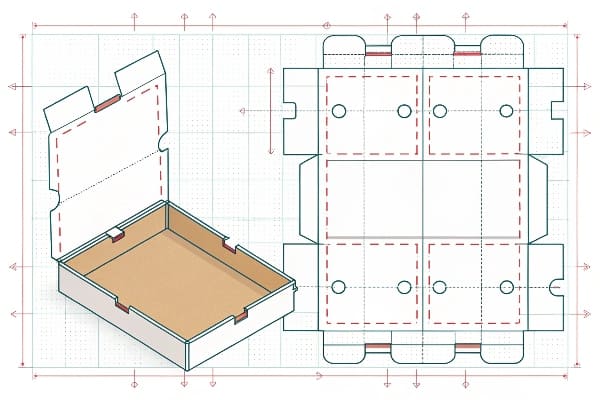

How to make dieline for packaging?

I see teams jump into artwork before structure. That causes rework. I start with the product, the shelf space, and the shipping carton. Then I build the dieline around real size.

Start with product dimensions and retail rules, choose board grade, draft the net in vector at 1:1, add cut/score layers, set bleed and safety, label panels, and validate with a physical sample.

A simple, reliable workflow I use

I keep tools simple. I use Adobe Illustrator3 or ArtiosCAD for nets. I set units to millimeters. I lock the origin at bottom-left. I create swatches for CUT, SCORE, and PERF as spot colors. I build the net with exact math. I mirror tuck flaps and dust flaps. I set bleed to 3 mm for paperboard and 5 mm for corrugated. I keep safety at 4–6 mm4. I place glue tabs where load paths are low.

| Step | Goal | Tip from the floor |

|---|---|---|

| Measure product + fit | Prevent crush and rattle | Add 2–3 mm clearance for paperboard; 4–6 mm for corrugated |

| Pick material | Balance strength and print quality | For displays, record flute (E/B/C) and grain direction |

| Draft net | True geometry | Use rectangles + offsets; avoid freehand curves on knife lines |

| Add folds/cuts/perfs | Clear manufacturing signals | Keep each on a separate locked layer with spot colors |

| Set bleed and safety | Clean edges and readable text | Extend background into bleed; keep logos inside safety |

| Label panels | Remove guesswork | Name FRONT, BACK, LEFT, RIGHT, TOP; add assembly arrows |

| Preflight | Catch errors early | Outline fonts, embed images, convert spot instructions to 100% tints |

| Prototype and test | Validate strength and fit | I cut a white sample, do load and drop tests, then approve for print |

I run quick tests: edge crush, shelf fit, and ship-in-own-container if needed. For B2B buyers with deadlines, this order saves days. At PopDisplay, we share the dieline and a 3D render within one working day after the net is stable. That keeps artwork moving while we test.

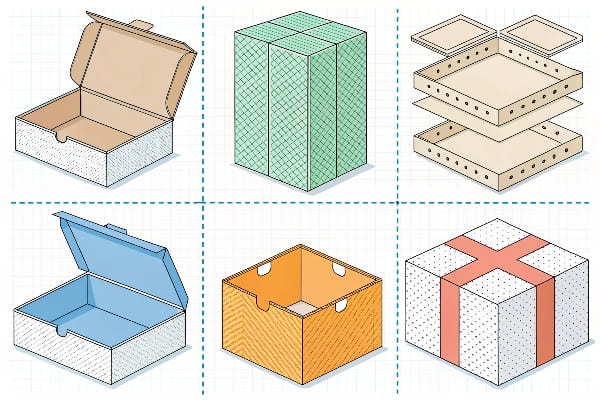

What are the different types of dielines?

Not all dielines are boxes. Retail uses many forms. I choose the form based on visibility, budget, and speed. The wrong choice adds cost and weakens sell-through.

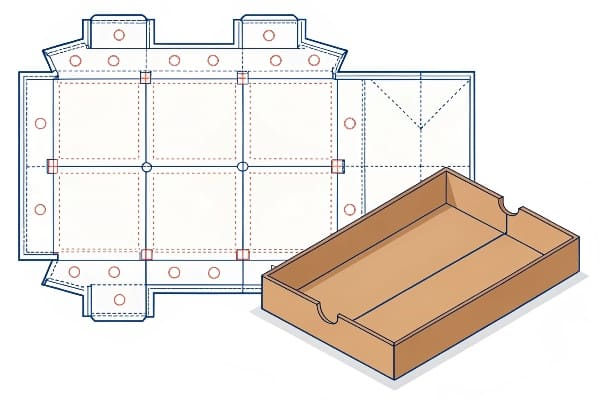

Common dieline types include folding cartons, corrugated mailers, trays, sleeves, PDQ inners, pallet skirts, floor displays, and inserts; each uses unique cuts, scores, and load paths to fit product and retail rules.

Picking the right dieline for the job

I sort by structure and retail goal. If a brand needs speed at checkout, I propose a PDQ tray that drops into a shelf. If the goal is big impact in an aisle, I move to a floor display with modular shelves. For eCommerce, I prefer mailers with dust flaps and tear strips. For gift sets, I add sleeves and windows. I check retailer specs for pallet heights and overhang rules. I also check the master carton count to hit logistics targets.

| Type | When I use it | Notes that save time |

|---|---|---|

| Folding carton | Light items, high print quality | Paperboard, tight tolerances, small bleed |

| Corrugated mailer | Shipping + unboxing | E/B flute, tear strip, double side locks |

| PDQ tray / shelf ready5 | Fast shelf load, impulse buys | Hand holes, perforated front, price zone |

| Floor display (FSDU)6 | Aisle impact, multi-SKU | Modular shelves, header, base skid |

| Pallet display | Club stores, bulk sell | 1/2 or full pallet, skirt wrap, corner posts |

| Sleeve/Wrap | Gift sets, seasonal refresh | Friction fit, window options |

| Insert/Fitting | Protect and present | Finger holes, nesting to reduce waste |

When I work with hunting gear like crossbows, I design inserts that lock limbs and cams. I mark "NO-PRINT" under glue pads. I make a reinforced base for heavy SKUs. That keeps displays stable in busy stores and reduces returns.

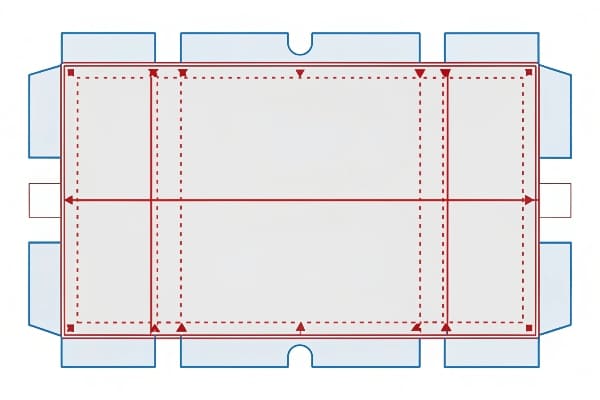

What does a dieline look like?

People expect a pretty picture. A true dieline is minimal. It communicates by lines and layers. The artwork sits on top, not inside the instructions.

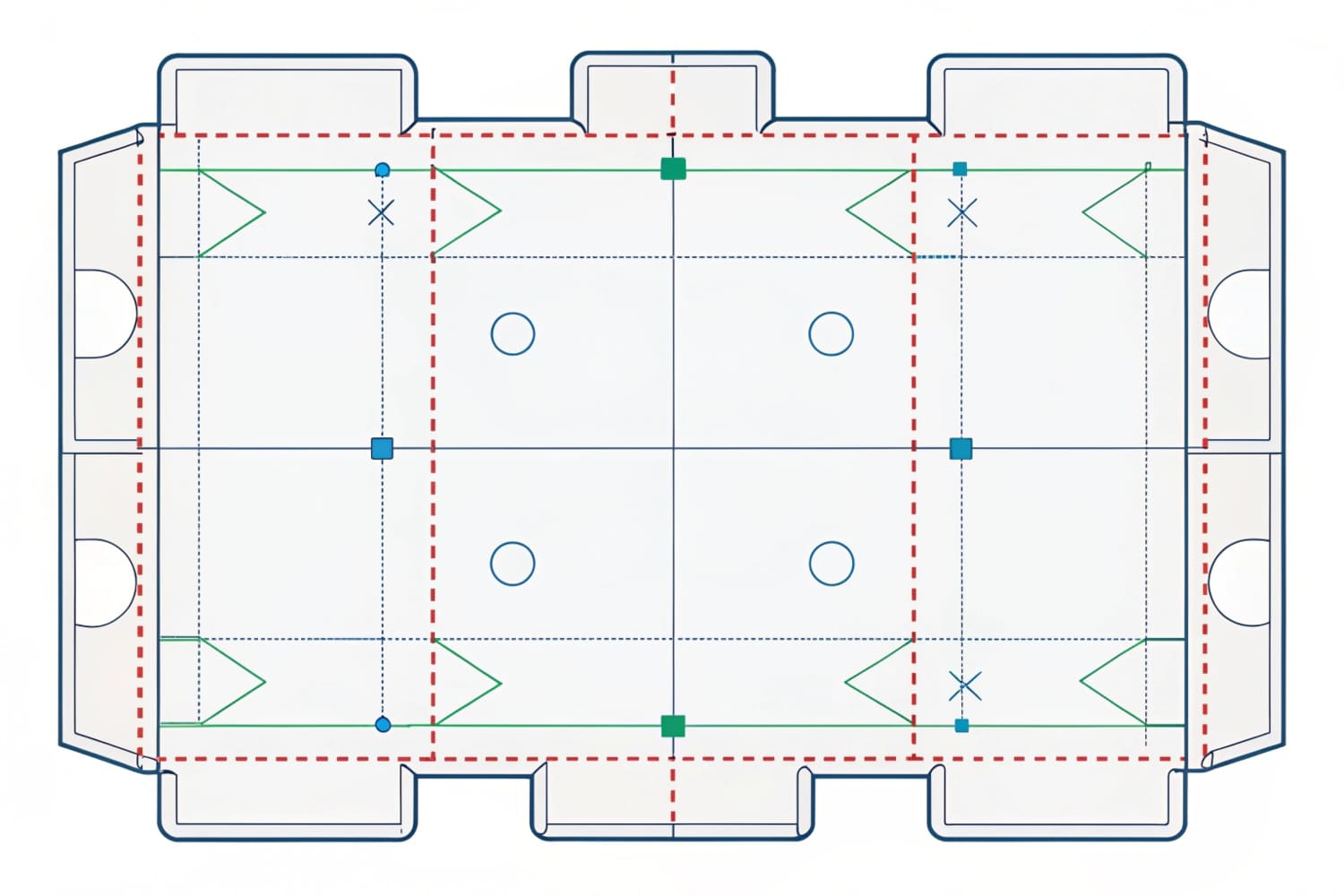

A dieline looks like a clean vector map with colored lines for cuts, dashed lines for folds, dotted lines for perforations, panel names, bleed and safety frames, glue zones, and simple assembly notes.

How I set up the visual language7

I avoid decoration on instruction layers. I keep contrast high and naming simple. I place artwork on a separate file or a locked layer group. I add a small legend so any printer can read it fast. I include a scale bar and units. I confirm the artboard size equals the die size. I put registration marks and color bars only on the print file, not on the dieline master, unless a printer asks.

| Line type | Color (spot) | Layer | Meaning |

|---|---|---|---|

| Cut | 100% Red | CUT | Blade path, finished edge |

| Crease/Score | 100% Blue | SCORE | Fold line |

| Perforation | 100% Green | PERF | Tear or bend |

| Bleed frame | 100% Magenta | BLEED | Extend artwork past trim |

| Safety frame | 100% Cyan | SAFE | Keep text/logos inside |

| Glue/No print | 100% Yellow | GLUE | Adhesive area, block ink |

I test readability in grayscale prints8, because some presses convert previews. I keep small text above 6 pt on paperboard and 8 pt on corrugated. I place barcode zones on flat panels, away from scores. I mark flute direction with arrows, because print cracking can ruin a premium look. Before mass production, I cut one white sample and dry fit the product. That step catches 90% of surprises.

Conclusion

A solid dieline removes guesswork, speeds artwork, and protects budgets. It makes packaging clear, strong, and ready for real stores and real deadlines.

Understanding dielines is crucial for effective design and print production, ensuring accuracy and quality. ↩

Exploring the concept of bleed helps ensure your designs are printed correctly, avoiding unwanted white edges. ↩

Explore these tutorials to enhance your skills in Adobe Illustrator, specifically for creating effective packaging designs. ↩

Understanding the importance of safety margins can significantly improve your packaging's effectiveness and prevent costly errors. ↩

Explore this link to understand how PDQ trays enhance retail efficiency and boost impulse purchases. ↩

Discover how floor displays can create impactful presentations and drive sales in retail environments. ↩

Understanding visual language is crucial for effective communication in design. Explore this link to enhance your design skills. ↩

Ensuring readability in grayscale prints is vital for quality. Discover tips and techniques to improve your print outcomes. ↩