I know deadlines can make or break a launch. Delays cost retail space, marketing windows, and buyer trust. I solve that fear with clear steps and proof-backed timelines.

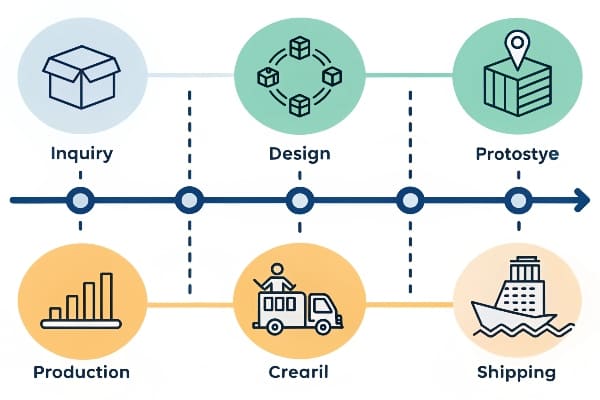

Our typical turnaround times are: structural design 1–3 days, white sample 2–4 days, print sample 4–7 days, mass production 7–15 days, and shipping based on route: express 3–7 days, air 7–12 days, sea 18–35 days.

I want you to keep reading because speed is not only a number. Real speed comes from process control, design clarity, and strong packaging. I will show how I plan, test, and protect your timeline from risk.

What Is Your Turnaround Time?

I know the first question is simple: "How fast can you deliver my displays?" Pressure is high when a retail reset or a product debut is locked in.

For standard custom cardboard displays, I deliver design in 1–3 days, sampling in 6–11 days total, production in 7–15 days, and logistics according to shipping mode. Rush options exist when artwork, purchase order, and approvals arrive on day one.

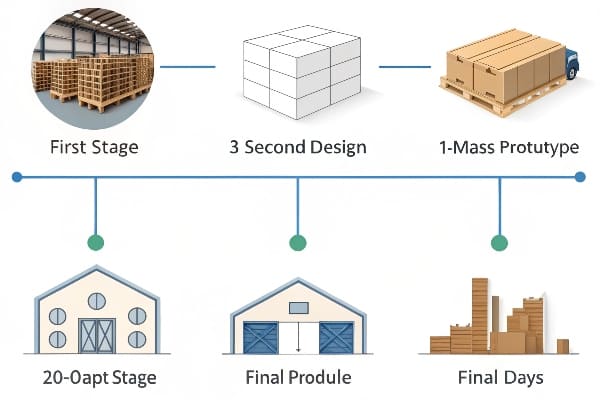

How I build a reliable clock

I keep timelines simple and visible. I break the project into fixed gates. I use short approvals to stop scope creep1. I also set buffers for color, strength, and transport. I use this flow because I once missed a seasonal promo early in my career. A U.S. client signed off late; a supplier changed board grade; the pallet failed a drop test. The chain reaction cost a valuable end-cap. I learned to lock specs, file proofs, and run tests before I book a vessel.\

Below is the baseline plan I follow for most B2B orders2 in the U.S., Canada, the U.K., and Australia. When artwork is final and decisions are fast, we beat these numbers. When scope grows, I show the impact same day.

| Phase | Deliverable | Typical Time | What I Need From You | Risk Guard |

|---|---|---|---|---|

| Design | CAD + 3D render | 1–3 days | Product dims, weight, brand guide | Fit check on day 1 |

| White Sample | Unprinted proto | 2–4 days | PO or sample request | Video assembly proof |

| Print Sample | Color-accurate proto | 4–7 days | Print files (CMYK/Pantone) | Color target + ICC proof |

| Mass Production | Finished units | 7–15 days | Sample approval | In-line QC, drop tests |

| Shipping | To your DC or 3PL | 3–35 days | Shipping terms | ISTA pack + overwrap |

What Is Turnaround Time in Manufacturing?

Deadlines live or die in the factory. Machines, people, and materials must move in sync. Any gap will slow the line and stack delays.

Turnaround time in manufacturing means the total time from approved spec to finished goods ready to ship. It includes material booking, printing, die-cutting, gluing, packing, QC, and palletizing.

The steps that speed production

I run three lines for corrugated POP. Each line has printing, die-cutting, and gluing paths tuned for short to mid runs. I plan shifts for seasonal peaks and North American resets. I pre-book recycled board grades that balance strength and cost. I keep inks and adhesives water-based and consistent, so color and cure times stay stable. In 2024, I moved more work to digital print3 for small-batch pilots. This cut make-ready, let us run variable graphics, and kept color tight across reorders.\

The best way to cut days is to remove surprises. I lock ECT or BCT targets and confirm flute before we print. I run transport simulations for pallet and PDQ trays. I use flat-pack designs to speed assembly at store level. My team films a full build and sends the clip with the sample; your team trains from that. We ship displays kitted with hardware, inserts, and simple manuals. This reduces store confusion and rework.

| Operation | Core Task | Time Driver | My Control Lever | Your Role |

|---|---|---|---|---|

| Material Booking | Board, liners, adhesives | Availability | Pre-book stock grades | Confirm target strength |

| Printing | Offset/digital/flexo | Make-ready, color | G7 targets, digital for short runs | Approve color proof fast |

| Die-Cutting | Tooling + cut | Tool lead time | Keep library of common tools | Choose from proven dies |

| Gluing | Auto-glue, hand-fit | Design complexity | Design for assembly (DFA) | Approve assembly video |

| QC & Pack | In-line checks | Sample variance | SPC checks, pull tests | Sign off on golden sample |

What Does Turnaround Time Mean in Shipping?

Even perfect production will fail if freight sits or routes wrong. Carriers, customs, and weather add real-world limits that I plan around.

Shipping turnaround time is the period from cargo ready date to delivery at your warehouse or 3PL, including booking, export, transit, customs, and final mile. Mode choice sets most of the timeline.

How I choose the right lane

I ship mostly to the United States, Canada, the United Kingdom, and Australia. I propose three lanes: express for samples or emergencies, air for small to mid rushes, and ocean for standard orders. I pick ports and carriers that fit your DC network. For U.S. lanes, I often ship to Long Beach, Los Angeles, Seattle, or Savannah, then truck to 3PLs. For Canada, I use Vancouver or Prince Rupert, or I air into Toronto. For the U.K., I use Felixstowe or Southampton. For Australia, I use Sydney or Melbourne.

I give a clean packing list, HS codes, and carton labels. I overwrap and corner-protect pallets. I request inspections when needed. I add humidity control if the route is hot or long. I once saved a hunting-season launch by moving a partial by air while the balance sailed. Stores got hero displays on time, and the rest filled in one week later. That split kept the reset intact and protected margin.

| Mode | Typical Door-to-Door | Best Use | Cost Level | Notes |

|---|---|---|---|---|

| Express Courier4 | 3–7 days | Samples, tiny urgent kits | $$$ | Easiest customs, highest cost |

| Air Freight5 | 7–12 days | Small–mid urgent runs | $$–$$$ | Good for phased rollouts |

| Ocean (FCL) | 23–35 days | Large standard orders | $ | Lowest unit cost |

| Ocean (LCL) | 25–40 days | Small economy orders | $ | More handling, add buffer |

What Is Customer Turnaround Time?

Your time matters too. Your approvals, files, and feedback set the pace. Clear inputs let me move fast with less risk.

Customer turnaround time is the time you take to provide artwork, approvals, and payments. Faster responses shorten the total lead time without extra cost.

How we cut the clock together

I work with brand owners, retail chains, franchises, and trading companies. Many come from the hunting, FMCG, and beauty sectors. A buyer like David at Barnett Outdoors runs new product tests and strict launch dates. He needs strong displays6 that ship on time to U.S. and Canada. We win these launches when the brief is clear on day one. The brief lists SKUs, weights, hero claims, Pantone colors, placements, and ship-to plans. My team returns a CAD and 3D render in 48 hours. David's team sends one round of edits and a color target. We lock the golden sample and move to mass production right away.\

Below is the response plan I share with all buyers. It tells who does what and when. It shows how we avoid color drift7, weak shelves, and missed resets. It is simple. It works. It turns repeat orders into the main profit driver, with only small design changes each season.

| Step | Your Action | My Action | Time Saved |

|---|---|---|---|

| Day 0 | Send final dims, weights, brand guide, Pantones | Return CAD + 3D within 48h | 2–3 days |

| Day 2–3 | One-pass design feedback | Update CAD same day | 1–2 days |

| Day 3–5 | Approve white sample via video | Start print sample prep | 1 day |

| Day 6–11 | Approve print sample colors fast | Book materials and line | 2–4 days |

| Day 12+ | Share weekly status in one thread | Keep QC photos flowing | 1–3 days |

Conclusion

Fast lead times come from clear briefs, quick approvals, and tested designs. I keep each step simple, visible, and backed by proof so your launch stays on schedule.

This link will offer valuable techniques to manage and prevent scope creep, helping you maintain project timelines and budgets. ↩

Exploring this resource will provide insights into effective strategies for handling B2B orders, ensuring efficiency and reliability. ↩

Explore how digital print can enhance efficiency and flexibility in packaging production. ↩

Explore this link to understand how Express Courier can expedite your shipping process and ensure timely deliveries. ↩

Discover the advantages of Air Freight for urgent shipments and how it can optimize your logistics strategy. ↩

Explore this link to learn how to design impactful retail displays that attract customers and boost sales. ↩

This resource will provide insights on maintaining color accuracy in your displays, ensuring brand consistency. ↩