Shoppers stop for what looks good. Teams ship what protects well. Deadlines do not wait. I face these truths in every project, so I keep my box choices simple.

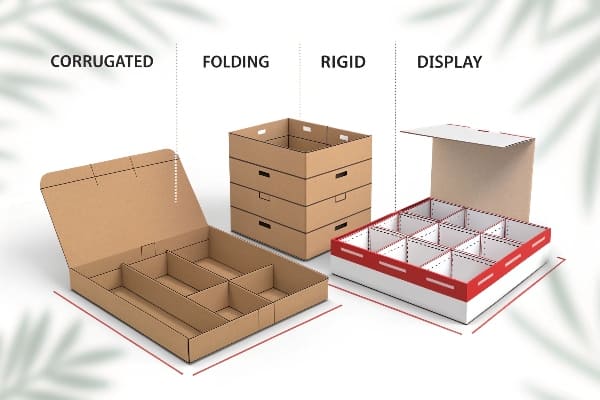

Paper box packaging falls into five practical groups: folding cartons, corrugated mailers and shippers, rigid setup boxes, specialty gift boxes, and display-ready PDQ trays. I match the box to weight, shelf goals, shipping risk, and print needs.

I run a cardboard display factory, so I test designs fast. I print samples, load them, and drop test them. I choose the lightest structure that protects and also sells.

What are the different types of paper packaging boxes?

Retail teams often feel lost. So many names for similar things. I cut the list to the formats that move sales, protect stock, and control cost.

The main types are folding cartons, corrugated mailers, shipping shippers, rigid setup boxes, sleeves and wraps, and display-ready PDQ trays. Each type fits a weight range, print style, and assembly speed. I choose by product risk and shelf plan.

Core families I use

I group boxes by job. Folding cartons1 look clean and print well. They fit light items and fast lines. Corrugated mailers and shippers take hits in transit. They protect heavy gear and e-commerce sets. Rigid setup boxes2 feel premium and hold shape. They suit gifts and launch kits. Sleeves and wraps add branding at low cost. PDQ trays and shelf-ready boxes go from carton to shelf in minutes. I standardize dielines to speed quotes and reduce tooling. I also set clear weight limits for each style. This keeps teams safe from crush and bow.

| Type | Structure | Strength | Best For | Notes |

|---|---|---|---|---|

| Folding Carton3 | Paperboard (SBS/FBB) | Low–Medium | Cosmetics, snacks | Crisp print, low cost |

| Corrugated Mailer4 | E/B/C flute | Medium–High | E-com, kits | Self-locking, no tape |

| Shipper (RSC) | B/C flute | High | Wholesale, pallets | Lowest unit cost |

| Rigid Setup | Greyboard + wrap | Medium | Premium gifts | High perceived value |

| Sleeve/Wrap | Paperboard | Low | Value add | Pairs with inner tray |

| PDQ / SRP | Corrugated | Medium | Impulse buys | From box to shelf fast |

What is the best paper for box packaging?

Teams chase "the best" paper and lose time. There is no single winner. The right sheet depends on weight, finish, and budget.

For print and retail, SBS or FBB works best. For strength and e-commerce, kraft-liner corrugated works best. For premium feel, wrapped greyboard works best. I pick by weight, finish, and supply risk.

Paper grades that work in real jobs

I use SBS (solid bleached sulfate)5 when color matters. Whites look clean. Skin tones hold well. I use FBB when I want more stiffness at similar caliper. I choose CCNB or recycled board for inner parts or sleeves to save cost. For mailers and shippers, I select kraft liner outside and test liner inside. I check ECT or burst to match weight and route. Humid lanes need higher spec. For premium rigid boxes6, I wrap greyboard with art paper or specialty paper. A matte film or water-based varnish protects from scuff. I avoid plastic lamination when buyers ask for easy recycling. When buyers need wet strength, I add aqueous barrier or a thin dispersion coating that still recycles.

| Grade | Look | Strength | Typical GSM/Caliper | Use Case | |

|---|---|---|---|---|---|

| SBS (C1S/C2S)7 | Bright white | Medium | Excellent | 250–400 gsm | Beauty, pharma |

| FBB | White, stiffer | Medium | Very good | 250–400 gsm | Food, retail |

| CCNB/Recycled | Grey back | Low–Medium | Good | 250–400 gsm | Sleeves, inner |

| Kraft Liner8 | Brown | High | Fair | 125–200 gsm liner | Mailers, shippers |

| Greyboard | Grey | Medium | Wrapped | 1–3 mm board | Rigid boxes |

What are the three types of boxes?

People often hear three core "box types" and want a quick rule. I use a simple map that helps teams pick fast and stay on budget.

The three common box types are folding cartons, corrugated boxes, and rigid setup boxes. They differ in cost, strength, and brand feel. I choose by weight, route, and customer touchpoint.

How I choose among the three

I start with the product weight and route. If the item is light and needs shelf beauty, I go folding carton9. If the item is heavy or ships alone, I go corrugated. If the item is a gift or launch kit, I go rigid. I then align print and finish. Foil and spot UV look sharp on SBS. Kraft needs bold art and strong contrast. Rigid wraps allow fabric textures and soft touch that wow buyers. I check assembly time next. Folding cartons run fast on lines. Corrugated mailers need fewer tools in pack rooms. Rigid boxes may need hand work, so I plan labor. In my factory, we pre-glue where we can and ship flat to cut freight. For outdoor or hunting gear, I add edge supports or inserts to stop tip and rub.

| Box Type | Cost | Strength | Brand Feel | Assembly | Typical Use |

|---|---|---|---|---|---|

| Folding Carton10 | $ | Low–Med | Clean, retail | Very fast | Beauty, FMCG |

| Corrugated11 | $$ | Med–High | Rugged, eco | Fast | E-com, wholesale |

| Rigid Setup | $$$ | Medium | Premium, gift | Slow | Launch kits, VIP |

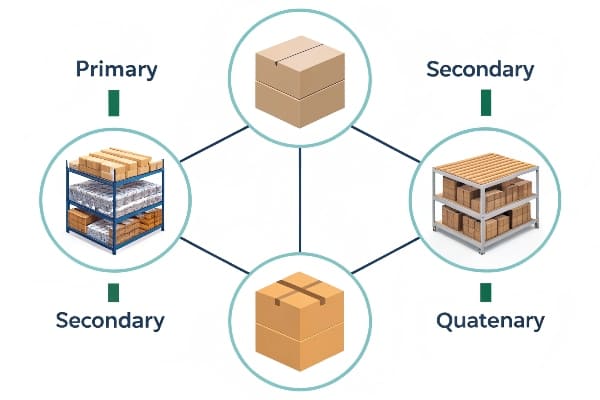

What are the four main types of packaging?

Teams also hear "four packaging levels" and get mixed advice. I keep it clear and tie each level to a paper solution that works on shelf and in transit.

The four types are primary, secondary, tertiary, and quaternary (unit load). Primary touches the product. Secondary groups units. Tertiary protects for shipping. Quaternary moves pallets. I design each level to hand off cleanly.

Definitions and practical picks

Primary packaging is what the shopper opens first. I use folding cartons with food-safe or low-VOC inks when needed. Secondary packaging groups units for the shelf. I use PDQ trays12, wraparound sleeves, or shelf-ready cartons that tear open clean. Tertiary packaging is the shipper. I use RSCs with right ECT and corner protection. Quaternary is the unit load. I use pallet patterns, top sheets, and edge guards that stop crush. I plan perforations so staff set displays fast. I add scannable panels for stock control. When I helped a hunting brand launch a crossbow, we used a strong mailer with E-flute inner and B-flute outer. The primary box sold the look. The PDQ tray lifted impulse add-ons near the counter. The pallet plan hit a warehouse pick path, so stores rolled out in one move. The team met a tight date and kept returns low.

| Level | Goal | Paper Solution | Example |

|---|---|---|---|

| Primary | Protect and inform | Folding carton or rigid13 | Cosmetic box, gear box |

| Secondary | Group and sell | PDQ/SRP tray, sleeve | Counter unit, shelf tray |

| Tertiary | Ship and protect | Corrugated RSC/FPF14 | Master carton, mailer |

| Quaternary | Unitize and move | Pallet + edge guard | Club store pallet display |

Conclusion

Paper box choices are simple when I link weight, route, and shelf goals. I test fast, print smart, and pick the lightest safe structure. This keeps costs low.

Explore this link to understand how folding cartons enhance product presentation and efficiency in packaging. ↩

Discover the unique benefits of rigid setup boxes for premium packaging solutions and their impact on customer perception. ↩

Explore the advantages of Folding Carton packaging for cost-effective and visually appealing solutions. ↩

Learn how Corrugated Mailers enhance shipping processes and reduce costs for e-commerce businesses. ↩

Explore this link to understand the benefits and applications of SBS in packaging, ensuring quality and aesthetics. ↩

Discover the advantages of premium rigid boxes, including durability and design, to enhance your packaging strategy. ↩

Explore this link to understand how SBS paper enhances packaging in beauty and pharmaceutical industries. ↩

Discover the advantages of Kraft Liner for shipping solutions and its impact on sustainability. ↩

Explore this link to understand how folding cartons can enhance product presentation and reduce shipping costs. ↩

Explore the advantages of Folding Carton packaging for beauty and FMCG products, enhancing your understanding of its retail appeal. ↩

Discover why Corrugated packaging is ideal for e-commerce and wholesale, ensuring product safety and sustainability. ↩

Exploring PDQ trays can reveal innovative ways to boost product visibility and sales at retail locations. ↩

Explore this link to understand how folding carton or rigid packaging can enhance product protection and presentation. ↩

Learn about corrugated RSC/FPF packaging to discover its benefits for shipping and protecting products effectively. ↩