Retail floors change fast. Shoppers skim. Displays fight for attention. I focus on formats that win quickly, ship flat, and set up fast, so teams sell more with less waste.

The main types of POP displays are floor, countertop, pallet, shelf/tray, dump bin, endcap, clip strip/hang tab, standee, and interactive units; choose by goal, product weight, footprint, retailer rules, and launch timing.

I build cardboard displays for global brands. I test what holds weight, what ships clean, and what passes buyer checks. Below, I break each question into clear answers you can use today.

What are the different pop displays?

Many teams buy the wrong format first. The wrong format wastes budget and time. I start with the shopper path and the product weight, then I match a format that fits both.

Key POP display types include floor displays, countertops, pallets, shelf/tray boxes, dump bins, endcaps, clip strips/hang tabs, standees, and interactive units; pick based on weight, space, and retailer rules.

Common families and where they win

I group displays by the job they do. Floor displays1 carry volume and tell a story from a distance. Countertops catch last-second interest. Pallet programs2 land fast in warehouse clubs. Shelf trays fix blocking and keep facing neat. Dump bins move clearance or small packs. Endcaps own traffic. Clip strips and hang tabs add facings without new shelf space. Standees add height and a face for the brand. Interactive units add motion or QR to hold attention. When I built a club pallet for a hunting brand launch, the simple rule was "no tools, two people, under three minutes." The unit shipped flat, locked with tabs, and held heavy gear with a hidden honeycomb base. Sell-through beat the base shelf by 38% in week one because shoppers could see and touch the product.

| Type | Best For | Footprint | Typical Material |

|---|---|---|---|

| Floor | Story + volume | Medium–Large | Corrugated3 |

| Countertop | Impulse smalls | Extra small | Paperboard/Corrugated |

| Pallet4 | Club speed | Pallet | Corrugated + Pallet Skirt |

| Shelf/Tray | Blocking + facings | Shelf bay | Corrugated |

| Dump Bin | Clearance/bulk smalls | Medium | Corrugated |

| Endcap | Traffic capture | Bay end | Corrugated |

| Clip Strip/Hang Tab | Add facings | Tiny | PET + Card |

| Standee | Awareness/character | Small | Corrugated |

| Interactive | Demo/QR | Varies | Corrugated + Device |

How many types of pop are there?

People ask for a number. There is no fixed count. Categories shift by retailer and region. I use a simple list so teams plan budgets and tooling with less debate.

There is no fixed number, but eight core families cover most needs: floor, countertop, pallet, shelf/tray, dump bin, endcap, clip strip/hang tab, standee/interactive; each has many size and strength variants.

My practical taxonomy for planning and costing

I use eight families to plan briefs, quotes, and timelines. This keeps teams aligned during reviews and lab tests. Each family has sub-types by weight class5, height, and ship-to-store method. A floor unit for snacks is not the same as one for power tools. We grade weight in tiers: light (≤2 kg per facing), medium (≤8 kg), heavy (≤20 kg+ with bracing). We also lock the assembly time goal6. Under three minutes is ideal for busy stores. When a buyer in the U.S. asked for "ten types for comparison," I mapped our eight families, then showed two variants per family with real photos and costs. The buyer saw overlap and cut the list fast. That saved one week and one round of sampling.

| Family | Light Variant | Heavy Variant |

|---|---|---|

| Floor | Header + shelves | Reinforced posts + base7 |

| Countertop | Die-cut stand | Weighted core8 |

| Pallet | PDQ trays | Full wrap + corner posts |

| Shelf/Tray | Auto-bottom tray | Metal hang bar add-on |

| Dump Bin | Single wall | Honeycomb liner |

| Endcap | Shipper with side wings | Frame with shelf lips |

| Clip/Hang | PET strip + cards | Wide strip + stoppers |

| Standee/Interactive | Flat standee | Screen/QR + power pack |

What are the different types of POS displays?

POS happens at checkout. Space is tight. Staff need speed. I keep structures small, safe, and easy to refill with one hand.

Typical POS displays include countertop trays, gravity feeders, peg racks with brand headers, small shippers, and digital callouts at cash wraps; they favor small packs, clear price tags, and fast refills.

POS-specific formats that convert in tight spaces

POS is not a place for big stories. It is a place for simple asks: "Try," "Add," or "Limited." I use gravity-feed trays9 for candy or small tools. I use peg racks with a small header for accessories. I add a price channel so staff can change tickets fast. I avoid wide footprints that block card readers. For one outdoor client, we placed a narrow two-tier tray beside the scanner. It held wax and string sets for crossbows. The tray sat on rubber feet, so it did not slide. Refill time was under 20 seconds. Attachment rate rose because the tray sat in the shopper's eye line while the cashier scanned the bow. When a retailer bans loose items at POS, I switch to a sealed PDQ shipper10 that opens into a neat tray in one pull.

| POS Format | Best Use | Must-Have |

|---|---|---|

| Countertop tray | Small add-ons | Price channel |

| Gravity feeder11 | High turns | Anti-tip base |

| Peg rack + header | Carded SKUs | Clear hooks |

| Mini shipper12 | Policy-safe | Tear-strip open |

| Digital callout | Services/QR | Short copy |

What is a pop in retail merchandising?

Teams use the word "POP" a lot. Some mean any display. Some mean a full promotion. I use a clear, simple meaning so briefs stay tight.

POP (Point-of-Purchase) is any in-store display or message that promotes a product at the place of shopping; it guides attention, frames choice, and speeds a decision.

Purpose, placement, performance

A POP unit does three jobs. It stops the shopper. It shows the offer. It makes the take easy. Good POP sits where the shopper can pause without blocking traffic. Copy is short. Price is clear. The structure matches weight and reach. I track three numbers: compliance13, sell-through lift14, and time to set. For a hunting gear endcap, we cut copy to five words, used a large hero image, and added a simple "Try me" band. Stores set it in two minutes because the shelf lips were pre-taped. Compliance hit 96% week one. Lift held after week three because we kept facings tight with anti-sag tabs. When I say "performance," I do not guess. I link UPCs on the plan to the display ID and check the lift against the control stores.

| KPI | How I Measure | Target |

|---|---|---|

| Compliance | Photo + checklist | ≥90% W1 |

| Set Time | Staff timing | ≤3 minutes |

| Sell-Through Lift15 | POS vs control | +15–30% |

| Damage Rate16 | QA logs | ≤1% of units |

What are pop materials?

Materials decide strength, print, and cost. Bad picks cause sag, color shifts, and delay. I set the material at brief stage, not at the factory gate.

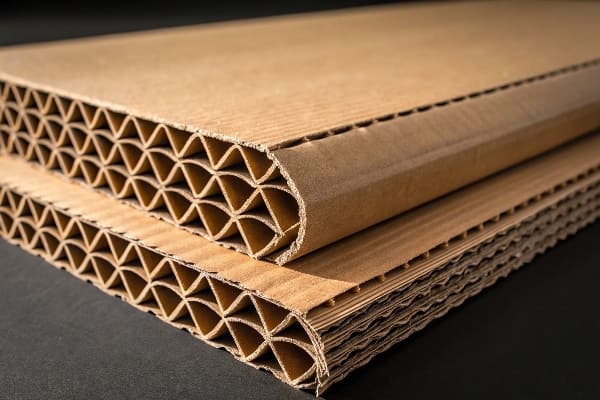

Common POP materials are corrugated cardboard, paperboard, foam board, honeycomb board, PET for windows or strips, and mixed builds with wood or acrylic; choose coatings, inks, and glues that meet retailer and recycling rules.

Material choices and trade-offs I see in real projects

Corrugated is my base for most units. It ships flat, prints well, and recycles in curbside streams. I use E-flute for crisp print and small trays. I use B/C-flute or double wall for heavy loads. For wet areas, I add water-resistant varnish17 or a thin barrier that still recycles. I avoid glossy films when a retailer bans plastic lamination. Water-based inks match most specs and reduce odor. For heavy gear, I hide a honeycomb board in the base or add corner posts. When a buyer asked for 20 kg per shelf, we built a test rack and ran drop, vibration, and load tests. The sample passed at 24 kg with less than 2 mm sag. Color stayed true after we locked a GRACoL profile and ran a press proof.

| Material | Strength | Sustainability18 | Typical Use | |

|---|---|---|---|---|

| Paperboard | Low | High | High | Small cartons, headers |

| Corrugated (E) | Medium | High | High | Trays, trays with headers |

| Corrugated (BC/DW) | High | Medium | High | Floor, pallets |

| Honeycomb19 | Very high | Low | High | Bases, risers |

| Foam board | Medium | High | Medium | Signs, light panels |

| PET/Acetate | N/A | Window | Medium | Windows, strips |

| Wood/Acrylic | Very high | High | Low | Semi-permanent |

What is the difference between POP and POS?

People mix these terms. Stores use them in different ways. I use a clean split so copy, size, and tests match the right spot.

POP covers all in-store promotional displays across the shop floor; POS sits at checkout or payment areas; POP builds awareness and comparison, while POS drives quick add-on buys with small footprints.

Practical differences that change design, print, and testing

I treat POP as the big field: aisles, ends, pallets, windows, and event zones. These units can be tall and hold volume. Copy can tell a short story. I treat POS20 as the last step: counters and cash wraps. These units must be small, safe, and fast to refill. Many retailers use the words loosely, so I always quote the exact placement on the planogram21. That stops re-work. For a club in North America, the buyer called a pallet "POS," but the real spot was a race track aisle. We raised header height to 60 inches, added side messaging for 360-degree view, and passed their fork-lift test. For a pharmacy chain, the "POS" tray had to be under 8 inches deep to keep the scanner clear. That small detail saved the program.

| Aspect | POP | POS |

|---|---|---|

| Location | Aisles, endcaps, floors | Checkout/cash wrap |

| Goal | Awareness + comparison22 | Add-on purchase23 |

| Size | Small to large | Very small |

| Copy | Short story + price | Few words + price |

| Tests | Load, wobble, ship | Tip, touch, hygiene |

| Refill | Staff or rep | Staff only |

Conclusion

Pick the format by job, weight, and space. Lock materials early. Keep copy short. Test fast. Ship flat. Then displays work, stores smile, and products move.

Explore how floor displays can enhance visibility and storytelling in retail environments, driving customer engagement. ↩

Learn about the effectiveness of pallet programs in boosting sales and attracting customers in warehouse settings. ↩

Explore the advantages of corrugated materials, including durability and sustainability, to enhance your packaging strategy. ↩

Learn how pallets streamline logistics and reduce costs in supply chain management, making them essential for businesses. ↩

Understanding weight class is crucial for effective product planning and can optimize logistics and costs. ↩

Exploring assembly time goals can reveal strategies to enhance efficiency and customer satisfaction in retail environments. ↩

Explore this link to understand how reinforced posts and bases enhance durability and stability in furniture. ↩

Discover why a weighted core is essential for countertop stability and how it can enhance your furniture's performance. ↩

Explore how gravity-feed trays can enhance product visibility and increase sales efficiency in retail environments. ↩

Learn about the advantages of using sealed PDQ shippers for organized and efficient product presentation at the point of sale. ↩

Explore this link to understand how gravity feeders can enhance product visibility and sales efficiency. ↩

Discover strategies for using mini shippers to maximize your marketing impact and drive customer engagement. ↩

Exploring compliance measurement techniques can help optimize your retail displays for better customer engagement. ↩

Understanding sell-through lift can enhance your retail strategies and improve sales performance. ↩

Understanding Sell-Through Lift can help you optimize sales strategies and improve inventory management. ↩

Exploring ways to reduce Damage Rate can enhance profitability and operational efficiency. ↩

Explore this link to understand the benefits and applications of water-resistant varnish in sustainable packaging solutions. ↩

Exploring this link will provide insights into how sustainable packaging can benefit the environment and businesses. ↩

This resource will explain the unique benefits of honeycomb materials, including strength and lightweight properties. ↩

Understanding the distinction between POS and POP can enhance your retail strategy and improve customer engagement. ↩

Exploring planograms can provide insights into effective product placement and maximize sales potential. ↩

Explore this link to discover proven strategies that can enhance customer awareness and facilitate product comparison. ↩

This resource provides insights into techniques that can effectively boost add-on purchases, maximizing sales opportunities. ↩