Manufacturing high-quality displays requires precision at every stage. If you choose the wrong cutting method for your packaging, your assembly line slows down, the edges look rough, and the structural integrity of the box is compromised. Let's fix that confusion right now and look at the tools that shape your brand.

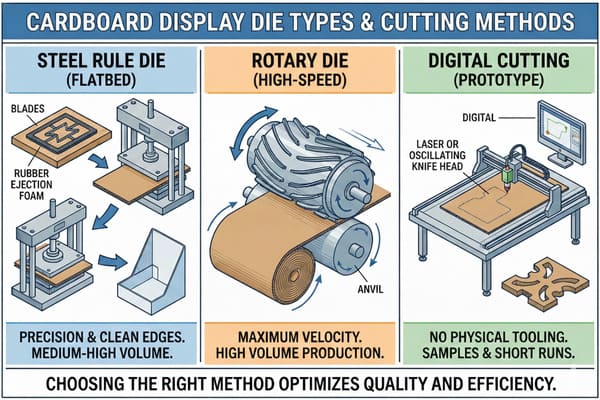

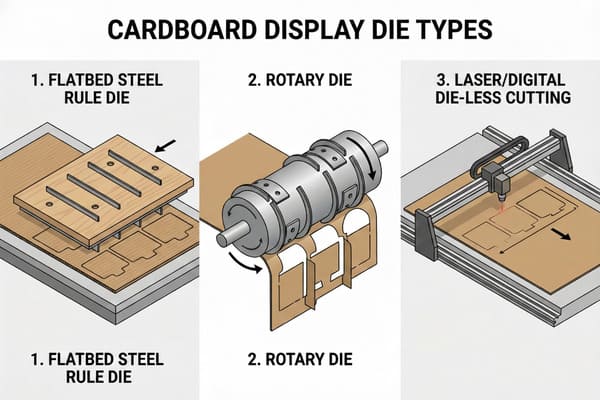

Die types in the cardboard display industry refer to the specific tools used to cut and shape corrugated board. The main categories include steel rule dies for flatbed cutting, rotary dies for high-speed production, and digital cutting for prototype samples without physical tooling.

Understanding these tools is not just about mechanics; it is about saving costs on your next retail rollout and ensuring your heavy products stay secure. Let's look at the specific numbers and options available to you.

How many types of dies are there?

Many buyers think all cutting happens the same way. This misconception leads to overspending on tooling fees for small production runs or accepting lower quality finishes on high-end retail displays.

There are primarily three main categories of dies used in cardboard display manufacturing: flatbed steel rule dies, rotary dies, and laser/digital die-less cutting. Each serves a distinct purpose based on production volume, material thickness, and precision requirements for the final retail structure.

The Strategic Selection of Cutting Tools

When we plan a production run for heavy-duty items like hunting gear or beverages, we have to match the die type to the volume and quality needs. The industry generally operates with three distinct technologies.

First, we have Steel Rule Dies (Flatbed)1. This is the industry standard for Point-of-Purchase (POP) displays. It uses a flat plywood base with steel blades inserted into laser-cut slots. The precision here is excellent, usually around +/- 0.5mm. It is perfect for orders between 500 and 5,000 units. The cut is clean, vertical, and crisp, which is essential when you want your branding to look premium in a store like Cabela's or Walmart.

Second, there are Rotary Dies. These are cylindrical dies used on high-speed flexographic machines. They are designed for massive volume—think 20,000 to 100,000 shipping boxes. However, the nature of rotary cutting means the blade rolls over the cardboard, which can slightly crush the corrugated flutes at the edge. For a high-end display, this "crushed edge" might be visible, which is why we rarely use rotary dies for the main body of a premium display, though they are great for invisible internal support fillers.

Third, we have Digital Cutting (Die-less)2. Machines like Kongsberg or Zund use a vibrating knife or laser. There is no physical wood or steel tool. We use this exclusively for prototyping. It allows us to cut one single unit for you to test. The edge quality is perfect, but the speed is slow. You cannot run mass production this way because it would take too long, but it is the secret to our "zero sample fee" policy.

| Feature | Flatbed Steel Rule Die | Rotary Die | Digital Cutting (No Die) |

|---|---|---|---|

| Best Volume | 500 – 10,000 units | 20,000+ units | 1 – 50 units (Samples) |

| Tooling Cost3 | Moderate ($200 – $600) | High ($1,500 – $3,000) | $0 (No tooling) |

| Edge Quality | Clean, Vertical | Slightly Crushed | Perfect, Sharp |

| Production Speed4 | Medium | Very High | Slow |

| Flexibility | Moderate | Low (Hard to change) | High (Instant changes) |

I know that paying for molds feels like a waste of money when you are just starting a new campaign. That is why I use digital cutters for your prototypes to keep costs zero until you approve the design. Once we move to mass production for your US retail launch, I switch to high-precision steel rule dies to ensure every tab locks perfectly without costing you a fortune in rotary tooling.

What are the 4 types of death?

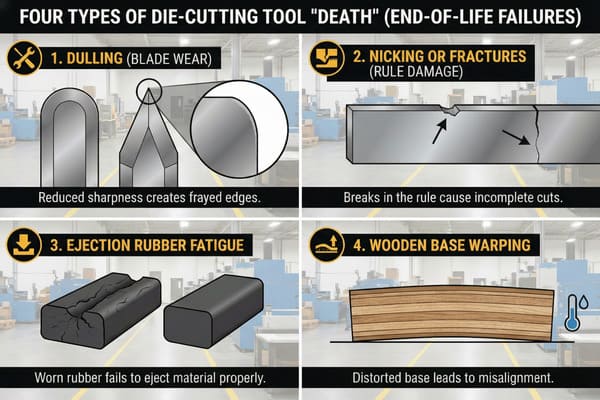

Searching for technical terms often brings up confusing results. In manufacturing, we don't deal with mortality, but we do deal with four critical "end-of-life" failures for a die that can ruin a production run.

In the context of die-cutting tool maintenance and lifespan, the four types of failure include dulling of the cutting blade, nicking or fractures in the rule, ejection rubber fatigue, and wooden base warping. Identifying these early prevents poor cuts and production delays.

Managing Tooling Longevity and Quality

When we talk about the "death" of a die, we are talking about the point where the tool is no longer safe or effective for production. Using a "dead" die results in displays that do not fold correctly or look ragged. Here are the four specific failure modes we monitor in the factory:

1) Blade Dulling5: Corrugated board contains recycled content, which often has traces of clay and minerals. This acts like sandpaper on the steel blades. When a blade dies from dulling, it requires more pressure to cut. This excess pressure crushes the cardboard flutes. If you are selling heavy crossbows, crushed flutes mean your display loses up to 30% of its vertical stacking strength.

2) Rule Fractures: This happens when we try to cut material that is too thick for the rule height, or if a scrap of paper gets stuck. The steel blade literally snaps. This causes a "skip" in the cut, meaning the waste paper won't detach. We then have to rip it manually, leaving an ugly, torn edge on your product display.

3) Ejection Rubber Fatigue6: Surrounding the blades are strips of rubber sponge. Their job is to bounce the cardboard off the blade after the cut. Over time, this rubber loses its "spring." When this part dies, the cardboard gets stuck in the machine, causing jams and slowing down your delivery timeline.

4) Base Warping: The plywood base holds everything together. If the factory humidity is not controlled, the wood swells or warps. This shifts the position of the blades by fractions of a millimeter. For a simple box, this is fine. For a complex display with precise locking tabs, a warped base means the display will not assemble correctly in the store.

| Failure Mode | Cause | Impact on Your Display | Prevention Strategy |

|---|---|---|---|

| Blade Dulling7 | Abrasive paper dust | Crushed edges, lower strength | Regular sharpening cycles |

| Rule Fracture | Over-pressure / Jams | Tearing, rough visual edges | Pressure calibration |

| Rubber Fatigue8 | High cycle count | Machine jams, delays | Replace rubber every 50k hits |

| Base Warping | Humidity changes | Assembly tabs won't fit | Climate controlled storage |

I never let a worn-out tool touch your production run because I know it ruins the edges and weakens the structure. My team performs maintenance checks after every 1,000 hits. If a die shows signs of fatigue during your order, I replace the blades immediately at my own cost to guarantee your hunting displays stand straight and look professional.

What are the different forms of die?

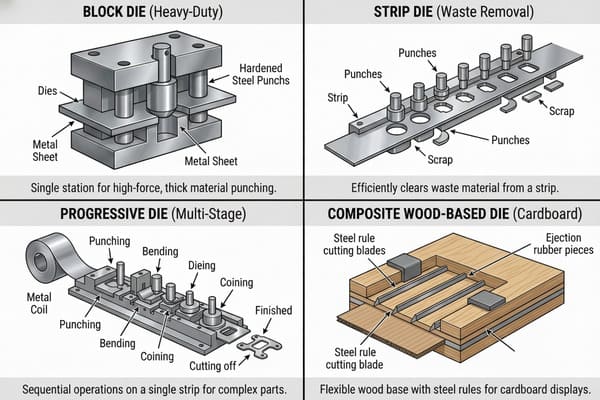

You might see terms like "strip die" or "block die" on an invoice. Knowing the physical form of these tools helps you understand what you are paying for and how the waste material is handled.

The different forms of die configurations include block dies for heavy-duty punching, strip dies for removing waste material, and progressive dies for multi-stage intricate cuts. In cardboard display production, we mostly utilize composite wood-based dies with embedded steel rules for optimal flexibility.

Technical Configuration of Die Boards

The form of the die dictates how we process the material. In the POP display industry, we rarely use solid metal block dies (which are used for cutting leather or heavy gaskets). Instead, we focus on highly configurable forms that allow for complex shapes.

The Composite Wood Base9 is the most common form. We use laser cutters to burn thin slots into a sheet of 18mm Russian Birch plywood. This wood is chosen because it is incredibly stable and does not warp easily. Into these slots, we hammer the steel rules.

Within this form, we use different "rule profiles." We have the Cutting Rule, which is sharp like a razor. We have the Creasing Rule, which has a smooth, rounded top. The creasing rule crushes the flute to create a fold line without cutting the liner. This is critical for your "easy assembly" requirement. If the creasing rule is too sharp, it cracks the liner; if it is too low, the box won't fold square.

We also use Stripping Dies10. These are a secondary form of die that works in tandem with the cutting die. While the cutting die shapes the box, the stripping die pushes out all the internal window cutouts and scrap pieces automatically. For complex displays with many holes (like a shelf holding vertical products), a stripping die is essential to ensure you don't receive displays full of hanging paper scraps (chad).

| Component | Material | Function | Why it matters for PopDisplay |

|---|---|---|---|

| Base Board | Laser-cut Birch Plywood11 | Holds blades in position | Ensures consistent dimensions |

| Cutting Rule | Hardened Steel12 (2pt-3pt) | Cuts through the board | Creates the shape |

| Creasing Rule | Rounded Steel | Crushes flutes to fold | Allows easy in-store assembly |

| Stripping Pin | Metal or Plastic | Punches out waste | Clean, scrap-free delivery |

I supervise the die-making process to ensure we use the correct creasing rules for your specific board grade. If we use a standard rule on a heavy-duty hunting crossbow display, the paper will crack. I adjust the rule height and profile personally to ensure your branding area remains flawless during the folding process.

What is the most common type of die?

Most projects do not require exotic tooling. The industry relies heavily on one specific workhorse that balances price and performance perfectly for brands that need reliable retail presence.

The steel rule die is the most common type used in the packaging and display industry. It consists of a custom-lasered plywood base holding sharp steel blades. It offers the best balance between low tooling costs and high precision for typical retail quantities.

The Industry Standard: Steel Rule Die13 Construction

Why is the Steel Rule Die (SRD) the dominant tool in our factory? It comes down to the balance of agility and cost. An SRD can be manufactured in 1-2 days. If you spot a mistake in your artwork or decide to change the size of a product shelf, we can modify an SRD by pulling out the blades and re-lasering a section of the wood. You cannot do that with a solid rotary cylinder.

The construction allows for incredible versatility. We can mix different "pointages" (thicknesses) of steel. For a standard floor display, we use a 2-point rule (0.71mm thick). But for your heavy product trays, we might upgrade to a 3-point rule (1.05mm thick) to reduce deflection when cutting through double-wall (BC flute) corrugated board.

Furthermore, SRDs allow us to use "nicking14." A nick is a tiny interruption in the blade that keeps the cut part attached to the sheet just enough so it travels through the machine, but breaks away easily during stripping. The art of placement is crucial. Too many nicks, and the edge looks rough; too few, and the sheet falls apart inside the machine. Achieving this balance is what separates a novice factory from a professional partner.

| Feature | Steel Rule Die (SRD)15 | Solid Rotary Die16 | Impact on Buyer |

|---|---|---|---|

| Modification | Easy & Cheap | Impossible / Expensive | Allows last-minute design fixes |

| Material Range | E-flute to Triple Wall | Limited thickness range | Can handle heavy-duty loads |

| Precision | +/- 0.5mm | +/- 1.0mm (Drift) | Better fit for complex parts |

| Setup Time | 30-60 Minutes | 2-4 Hours | Faster start for your rush orders |

I always recommend steel rule dies for your seasonal promos because they allow us to change the design cheaply if the market shifts. For your crossbow displays, I use a specialized serrated rule that prevents sharp paper edges, keeping customers safe while they shop for your products in the aisles.

Conclusion

Selecting the right die type determines the quality, cost, and speed of your display production. By understanding the difference between digital samples and steel rule mass production, you can optimize your budget. I am here to handle these technical details, ensuring your displays arrive strong, clean, and ready to sell.

Explore this link to understand how Steel Rule Dies enhance production quality and efficiency in various industries. ↩

Discover the advantages of Digital Cutting for prototyping, including speed and precision, which can revolutionize your production process. ↩

Understanding tooling costs can help you choose the right die cutting method for your budget and production needs. ↩

Exploring production speed differences can guide you in selecting the most efficient die cutting option for your project. ↩

Understanding blade dulling can help improve production efficiency and product quality, ensuring better outcomes. ↩

Exploring this topic can provide insights into maintenance practices that enhance machinery longevity and reduce downtime. ↩

Understanding Blade Dulling can help improve your manufacturing process and product quality. ↩

Exploring Rubber Fatigue prevention can enhance machine longevity and reduce operational delays. ↩

Explore this link to understand the significance of Composite Wood Base in creating stable and complex die shapes. ↩

Learn about Stripping Dies and their role in enhancing efficiency and cleanliness in die board manufacturing. ↩

Explore this link to understand how Laser-cut Birch Plywood enhances precision and durability in various applications. ↩

Discover why Hardened Steel is crucial for cutting tools, ensuring longevity and efficiency in manufacturing processes. ↩

Explore the benefits of Steel Rule Die to understand its efficiency and versatility in production processes. ↩

Learn how nicking enhances the cutting process, ensuring quality and efficiency in production. ↩

Explore the benefits of SRD for efficient and cost-effective manufacturing solutions. ↩

Learn about Solid Rotary Die's capabilities and how it can enhance your production process. ↩