I see fragile goods fail in transit. I also see buyers lose trust fast. I solve that pain with simple, smart inserts that fit the product, absorb shock, and lower damage rates.

Product packaging inserts are custom-fit structures that hold and cushion products inside a box so items do not move, rub, or break during shipping, retail handling, and returns. They reduce damage, protect finishes, and improve the unboxing experience while keeping total packaging cost under control.

I will break this topic into clear parts. I will cover what inserts are, how retail inserts differ, what packaging types exist, and what an insert box means. I will add checklists, tables, and real tips.

What are packaging inserts?

Products get hurt when they move in a box. Corners take hits. Surfaces get scratches. I stop that movement with inserts that match the shape and the weight of the item.

Packaging inserts are shaped components placed inside cartons to immobilize and cushion products in transit, preventing shock, vibration, abrasion, and compression damage while guiding a tidy unboxing.

Why inserts matter, how they work, and what to check

I design every insert with one goal. I keep the product still. I choose material after I measure weight, fragility points, and stack height. I use corrugated for strength and cost. I use molded pulp1 or honeycomb for eco goals. I use foam only when I need precise cushioning or multi-drop protection. I always test for drop, vibration, and compression. I use simple pass/fail rules that any team can repeat. I keep the structure easy to assemble on the line. I avoid glue when locks or tabs can do the job. I plan for returns by making inserts reversible. I print clear marks so packers cannot flip parts wrong. I add pull tabs so users lift items without force. I keep tolerances tight so parts nest and ship flat. This keeps freight low and storage clean. Below is a quick map of common choices.

| Insert Type | Best For | Key Strength | Cost Level | Eco Fit |

|---|---|---|---|---|

| Die-cut corrugated2 | General goods | Stack + crush | Low | High |

| Molded pulp | Electronics, glass | Form fit + shock | Medium | High |

| Honeycomb board | Heavy items | High compression | Medium | High |

| EPE/EVA foam | Precision parts | Repeat drops | Medium–High | Medium |

| Paper void-fill | Low risk items | Fill space fast | Low | High |

What are retail inserts?

Stores judge products in seconds. If items look messy, buyers walk away. I use retail inserts to stage products and keep kits complete on shelf.

Retail inserts are display-focused inner trays or cards that hold products in a visible, tidy layout for shelf impact while still preventing scuffs and loss of small parts.

Form, function, and shelf rules that win

I build retail inserts3 with two aims. I fix the item position and I frame the brand. I pick paperboard or corrugated with clean edges for open-window boxes. I add thumb cuts so shoppers can remove and return items during demos. I add tamper tells near seals. I design cavities to match silhouettes so the eye reads the shape fast. I test color transfer with rub tests, because dark prints can mark light plastics. I specify a satin varnish4 to reduce glare behind clear PET windows. I keep assembly under 30 seconds. I lock small SKUs with tabs, not tape, so refill teams work faster. I use flat-pack designs for chain stores that demand PDQ trays. I print simple instructions on the back panel for merchandisers. I mark "Facing" lines so displays align on shelf. The table shows quick picks.

| Retail Insert | Use Case | Visual Goal | Speed to Pack | Theft Risk |

|---|---|---|---|---|

| Paperboard tray | Beauty, gadgets | Clean staging | Fast | Medium |

| Corrugated cradle | Heavier kits | Rigid hold | Medium | Medium |

| PET inner try | Window boxes | High clarity | Medium | Higher |

| Molded pulp tray | Eco lines | Natural look | Medium | Low |

| Clip strip card | Small add-ons | Cross-sell | Fast | Medium |

What are the different types of packaging for products?

I get many requests that mix outer boxes and inner parts. Teams confuse roles. I separate layers by job, then I pick materials by risk, route, and budget.

Product packaging includes outer shipping cartons, retail boxes, inner protective inserts, and secondary accessories like manuals and bags; each layer has a different job in protection and presentation.

Layers, jobs, and how to choose without waste

I define a simple stack. The outer shipper absorbs logistics abuse. The inner insert locks the item and spreads load. The retail box speaks to the shopper. The accessories keep surfaces clean. I begin with the route. Air parcels need drop control. Pallet freight needs compression control. I then map fragility points. I ask where cracks start. I choose a cushion curve that fits expected drops. Corrugated plus molded pulp5 covers most needs with low cost and high recyclability. Foam enters only when I have small hard parts or tight tolerances. I right-size the retail box so the insert fits with no rattle. I mark critical dimensions and limits on the dieline. I set a spec sheet so no one downgrades paper weight later. I run ISTA-style tests6 before I buy tooling. I lock print colors with a target and a delta E limit. This keeps color shifts away. Here is a quick map of roles.

| Layer | Job | Typical Material | Test Focus | Print Level |

|---|---|---|---|---|

| Shipper carton | Survive transit | Corrugated | Drop/Compression | None |

| Retail box | Sell on shelf | Paperboard/Corrugated | Scuff | High |

| Protective insert | Prevent movement | Corrugated/Pulp/Foam | Vibration | Low |

| Accessory | Clean or seal | Tissue/Bags | Chemical | Low |

What is an insert box?

Clients ask for an "insert box." Many mean a box that includes a shaped insert. Some mean a box built from inserts that lock together. I clarify before I design.

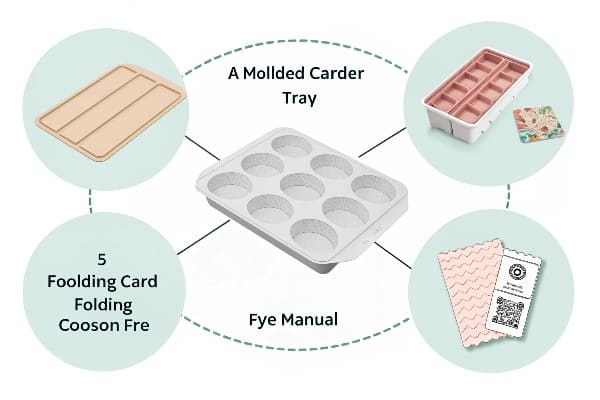

An insert box is a carton system that includes a custom-fit internal insert or tray which holds the product in place; the insert and box are designed as one unit.

Two common meanings and how I design each one

I see two uses of the term. The first is a retail or mailer box7 that comes with a die-cut tray or molded pulp that grips the item. The second is a modular set of interlocking panels8 that fold into both box and insert at once. I confirm the meaning with photos and a quick sample. For the first, I design the insert first, then I wrap the box around it. This keeps tolerances tight and the unboxing smooth. For the second, I design a one-piece structure with tabs and slots. This cuts assembly steps and glue. I keep flute direction aligned with compression loads. I add bridge ribs under the heavy zones. I notch cable paths if the item has cords. I add QR codes that link to recycling tips, not to long manuals, since this project focuses on protection, not instructions. The table sums up both styles.

| Insert Box Type | Structure | Best For | Assembly | Tooling Cost |

|---|---|---|---|---|

| Box + separate tray | Two-piece | Premium kits | Fast | Medium |

| One-piece lock insert | Integrated | High volume SKUs | Fastest | Low–Medium |

Conclusion

Protect the product first, then sell it. Pick the right insert, test it fast, keep it simple, and keep costs and waste low.

Explore this link to understand how molded pulp can enhance product protection and sustainability in packaging. ↩

Learn about the advantages of die-cut corrugated packaging for cost-effective and eco-friendly shipping solutions. ↩

Explore this link to discover effective strategies for creating impactful retail inserts that enhance product visibility. ↩

Learn about satin varnish and its advantages in packaging, including reducing glare and improving product presentation. ↩

Explore this link to understand how Corrugated plus molded pulp offers cost-effective and eco-friendly packaging solutions. ↩

Learn about ISTA-style tests to ensure your packaging meets industry standards and protects your products effectively. ↩

Explore this link to understand the design and functionality of retail or mailer boxes, enhancing your packaging knowledge. ↩

Discover how modular interlocking panels can optimize packaging design and efficiency, making your projects more innovative. ↩