I see shoppers pause and look. I know why. A good display box speaks fast. It solves clutter. It lifts a brand. It wins seconds that matter most.

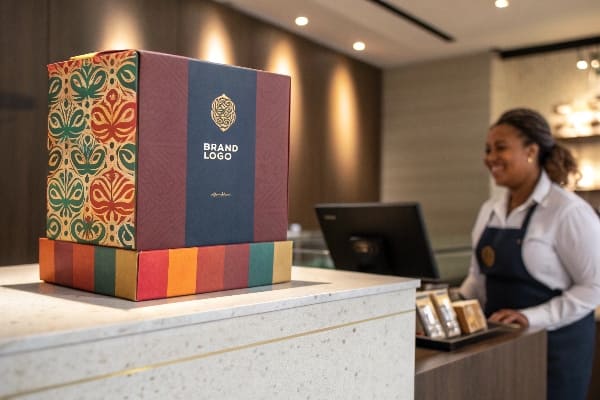

Custom product display boxes are branded paperboard or corrugated cartons engineered to hold, protect, and showcase items in retail. They are sized to the product, printed to the brand, and shaped for impact. They ship flat, assemble fast, and drive impulse buys.

I will show what they are, how they differ by use, and why they work. I will share my own factory lessons, from design to load tests, so you can plan without guesswork.

What are custom display boxes?

Shoppers move fast. Shelves feel crowded. Your product needs a small stage. A custom display box gives that stage, even when space is tight.

A custom display box is a printed, structural carton built to present products on counters, shelves, or floors. It merges packaging and merchandising. It guides placement, holds SKUs, and communicates value in seconds.

How a display box works in the real world

I use a simple rule in my factory: form follows retail. I start with the retail path1, then shape the box. Most brands jump straight into graphic design. I do the opposite. I map where the box will sit. Counter? Aisle? End cap? Club pallet? This sets footprint, height, and sight lines. I run a quick strength model based on unit weight and stack depth. I select single-wall or double-wall corrugated by target life. I plan flat-pack panels2 for low freight and fast set-up. Only then do I place print zones and brand cues.\

I test hooks, notches, dust flaps, and tuck locks. I test tear-away fronts for easy shop-out. I test perforations for clean reveal. I test gloss vs. matte for glare under store LEDs. I learned this on a seasonal health launch. The team wanted high gloss. The lights killed legibility. We switched to soft-matte with bold type. Sales rose in week two.

Core components and quick specs

| Part | Purpose | Typical Options |

|---|---|---|

| Back panel | Branding, claim space | Straight, arched, header add-on |

| Tray/base | Load, SKU layout | Single or divided cells |

| Tear front | Shop-out and access | Full or half perforation |

| Locks/tabs | Fast assembly | Tuck, crash, auto-lock |

| Material | Rigidity | Paperboard, single-wall, E-flute |

| Finish | Look and feel | Matte, gloss, soft-touch, water-based varnish |

What are custom retail boxes?

Retail has rules. Retail also has chaos. Custom retail boxes must respect both. They must protect in transit, then sell on shelf.

Custom retail boxes are product cartons designed for store sale and shelf impact. They combine protective structure with brand printing, barcode and compliance marks, and easy opening for staff and shoppers.

Retail box vs. display box: where they meet

A retail box travels far. It meets conveyors, trucks, and racks. It must pass drop and compression tests. A display box often stays in-store. It must pass quick set-up and daily touch. Many programs blend both. I build display-ready retail (SRP/PDQ) units3 that ship master-packed. Staff open along a perforation and place the tray straight to shelf. This saves minutes and keeps facings neat.\

I plan printing for two distances. From three meters, I show color block and logo. From one meter, I show benefit and variant. On club pallets, I spin the message on all four sides. For North America, I include bilingual labels if needed. For Europe, I plan eco marks and fiber sourcing icons. For APAC, I test red hues and gold foils with caution, since glare can hide claims under hard lights.\

I once supported a crossbow accessory launch for a US brand. The retail box needed rugged inner fitments and strict color match to the bow line. We ran draw-bar tests and used water-based inks to avoid odor in small shops. The boxes survived freight and sold clean on peg and shelf.

Retail box checklist

| Item | Why it matters | My tip |

|---|---|---|

| Barcode & compliance | Scans and legal | Print on flat, high-contrast area |

| Inner fitment | Protects parts | Use die-cut corrugate before foam |

| Color match | Brand trust | Use target LAB values, keep ΔE tight |

| Opening experience | Fights returns | Add simple pictograms |

| Sustainability | Shopper demand | Recycled content + water-based inks |

What is a custom box?

People ask this a lot. The term sounds broad. It is broad. It covers many use cases beyond retail.

A custom box is any packaging made to a specific product size, material, print, and function rather than a standard stock size. It can be shipping, retail, or display focused.

Types, materials, and when to use them

I sort custom boxes by job. A shipper protects. A display sells. A retail carton does both. I pick paperboard for light items with premium print. I pick corrugated for weight and rigid forms. Single-wall suits most PDQ trays. Double-wall suits tall floor units or heavy gear. For wet or high-traffic zones, I add a water-based barrier or nano-coating that still recycles. I keep dielines simple to speed assembly.\

Printing comes next. Digital print4 is fast for short runs and regional tests. It is great for seasonal or influencer editions. Flexo is efficient for large runs with solid colors and big type. Litho-label gives high detail for hero graphics. I match method to budget and timeline.\

One of my favorite wins came from a last-minute outdoor promo. The client needed 800 floor units in three weeks. We switched to modular columns with repeatable trays. We printed common parts and only changed header art. We hit the date and held strength in the field.

Quick decision table

| Need | Best pick | Reason |

|---|---|---|

| Fast turn, small run | Digital print PDQ | Low setup, high agility |

| Heavy product | Corrugated + inserts5 | Load and stability |

| Premium look | Paperboard + lamination | Clean edges, fine detail |

| Club store | Pallet display | Speed to floor, big impact |

| Sustainability | Recycled board + water inks | Meets buyer policy |

What are the benefits of custom boxes?

Retail is a fight for attention. Freight is a fight for cost. Waste is a fight for trust. Custom boxes help in all three.

Benefits include better shelf impact, fit-to-product protection, faster set-up, lower freight through flat-pack designs, improved sustainability with recycled fibers and water-based inks, and higher sell-through due to clear, brand-led storytelling.

Why the gains show up on the P&L

I track numbers on every project. Custom sizing cuts void space. That cuts inner fills and pallet air. Freight drops. Damage claims fall because fitments stop rattle and crush. Store teams like simple tear lines and auto-lock bases. Set-up time drops. Managers give us more placements because execution is clean. Shoppers notice the brand block. Sales lift.\

Sustainability matters to buyers and end users.6 Recycled content and clean coatings now show in scorecards.7 Many chains ask for this. Clear labeling helps recycling. Short-run digital lets me test claims and colors by region. If a green headline wins in the Midwest but not on the coast, I adjust art in the next print without waste.\

I saw this with a hunting accessories rollout tied to a new season. The buyer had strict deadlines and strength needs. We built a floor unit with single-wall posts plus hidden braces. We ran load and transport tests. We kept ΔE color difference tight across lots. We hit the date. The units held up through peak traffic. The client reordered with only minor art tweaks.

Benefit map

| Area | What improves | Business effect |

|---|---|---|

| Logistics | Flat-pack, right-size | Lower freight, easier inbound |

| Store ops | Fast assembly | Less labor, fewer errors |

| Brand | Big, clear cues | Higher awareness and trust |

| Sales | Better access and facing | More pickups, more units sold |

| ESG | Recycled fibers, water inks | Buyer compliance, shopper goodwill |

Conclusion

Custom display boxes turn space into sales. I design them to fit the product, the store, and the clock. The right box protects, sells, and scales.

Understanding the retail path is crucial for effective packaging design, ensuring products attract customers and maximize sales. ↩

Exploring flat-pack panels can reveal how they optimize shipping and storage, making them essential for efficient logistics. ↩

Explore this link to understand how SRP/PDQ units enhance retail efficiency and customer experience. ↩

Explore the benefits of Digital print for packaging, including speed and flexibility for small runs. ↩

Learn why Corrugated + inserts are ideal for heavy products, ensuring load stability and protection. ↩

Explore this link to understand how sustainability influences consumer choices and enhances brand loyalty. ↩

Discover the significance of recycled materials in product scorecards and their effect on brand perception. ↩