I sell cardboard displays. I also manage print timelines. I must explain offset printing in clear steps. This guide shows how the process works and how it helps retail projects.

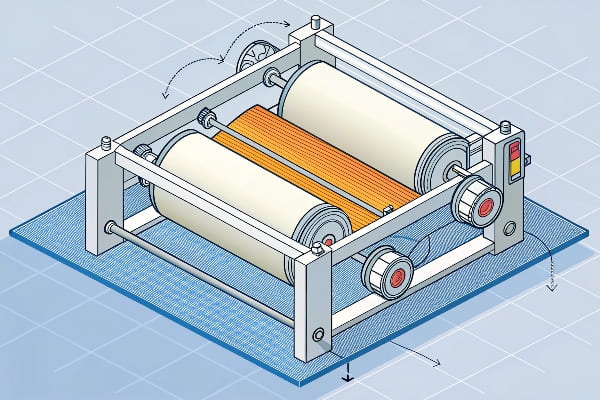

Offset printing works by transferring ink from a metal plate to a rubber blanket, then to paper or corrugated board. It uses CMYK or spot colors, precise plates, fast drying, and high-speed presses to deliver sharp, consistent results at scale.

I will keep this simple. I will map the core steps. I will show trade-offs. I will compare offset and digital. I will also answer if offset still matters today for POP displays.

What are the steps of offset printing?

I run many POP orders. Schedules are tight. If one step slips, the whole plan moves. These are the steps I watch each day.

The steps are prepress (files, color, imposition), plate making (CTP), press setup (mount plates, ink, register), printing (CMYK or spot), drying, finishing (lamination, die-cut), and quality checks throughout.

From file to plate

I start with clean artwork. I convert colors to CMYK1 or define spot inks. I set bleed, safety, and dielines. I check images at 300+ dpi for print. I run preflight to remove hidden RGB or overprint errors. I impose pages or panels to fit sheets and cutting tools. Then I send to CTP to image aluminum plates for each color.

On press and after

I mount plates on each unit. I load the right paperboard or corrugated liner. I ink up, set water balance, and pull make-ready sheets. I correct registration and density with a densitometer2. I start the run at speed. Sheets move to drying. We add coatings, laminate to corrugated if needed, then die-cut, fold, and glue. I log samples for traceability.

| Step | What I check | Tools |

|---|---|---|

| Prepress | Bleed, dieline, CMYK/spot, fonts | Preflight, proof |

| CTP | Plate integrity, screen ruling | 175–200 lpi plates |

| Make-ready | Registration, density | Densitometer, loupe |

| Printing | Color stability, scumming | QC sheets each 500 |

| Finishing | Size, fit, cracks | Die-cut gauge, fold test |

What are the disadvantages of offset printing?

I like offset for volume. Yet I must be honest about its limits. I plan buffers and talk early with buyers to avoid risk.

Offset has higher setup costs and longer make-ready, needs plates, prefers larger runs, has slower changeovers, limited variable data, potential color drift without QC, and more waste during setup.

Where offset can slow a project

Offset needs plates for each color. That adds time and cost. Short runs feel expensive because make-ready wastes sheets and ink3. If a design changes late, we must remake plates. Coatings and inks can mark or set-off if drying is rushed. Corrugated liners need care to avoid crush or warp. Color can drift with temperature or paper moisture. Variable data is hard, so unique codes or names are better on digital.

How I reduce these downsides

I batch SKUs that share stocks and inks. I lock artwork early with simple change control. I use standard dielines where I can. I request drawdowns for brand colors. I set clear delta-E targets. I plan for dummy sheets in the budget. For rush jobs or many versions, I shift to digital for top sheets, then mount to board.

| Disadvantage | Impact | Mitigation |

|---|---|---|

| Plate cost | Higher unit cost on small runs | Gang runs, lock art |

| Make-ready waste | Material loss | Tight SOPs, skilled crew |

| Slow changeovers | Lost time | Sequence SKUs, SMED |

| Limited variable data4 | Less personalization | Hybrid: digital elements |

| Color drift | Brand risk | Densitometry, closed-loop |

What is better, offset or digital printing?

Buyers ask this a lot. They want a quick answer. I give a clear one, then I show numbers and risk.

Offset is better for large, consistent runs with strict color and lower unit cost at scale. Digital is better for short runs, many versions, fast turns, and variable data. I often mix both for best value.

How I choose under a deadline

I look at run length, versions, color aims, substrate, deadlines, and budget. If I have one design and 30,000 units for a floor display, I use offset with a protective coating. If I have 12 versions for regions, each 500 units, I go digital for the top sheets and mount to E-flute. If I need metallics or special Pantone inks, offset wins with a spot color. If I need names, QR codes, or test images, digital wins. I test both for key colors to avoid surprises.

| Factor | Offset wins when | Digital wins when |

|---|---|---|

| Run length | 5,000+ units | Under 1,500 units |

| Versions | 1–3 SKUs | 4+ SKUs, micro-runs |

| Color | Spot/Pantone critical | CMYK good, fast |

| Special effects | Metallic, varnish combos | White ink on films, quick |

| Data | Static | Variable data |

Cost and time notes

Offset drops unit cost as volume climbs. Setup takes longer. Digital has higher unit cost but low setup. Turnaround is fast. For launch waves, I start with digital to hit shelves, then switch to offset for the big replenishment. That keeps sales on track and protects margin.

Is offset printing still used today?

I hear this often from new teams. They see fast digital proofing and think offset is gone. It is not.

Yes. Offset is widely used for packaging, magazines, catalogs, and POP displays. It remains the standard for large volumes, strict brand color, and high image quality on many paper stocks.

Where I still rely on offset for displays

I run offset when a retailer demands exact brand colors at scale. I use it for floor displays that need strong solids and fine type. I print top sheets for corrugated and then laminate. I add aqueous or UV coatings to resist scuff. I choose offset when cost per unit must stay low over tens of thousands of pieces. I plan QC at each stage. I keep retain samples for future reorders. I match reprints to the standard under D50 lighting.

How this fits market trends

Retailers want sustainable displays5. Offset supports water-based inks6 and recyclable boards. It pairs with light but strong structures to cut freight. It works with FSC and other certifications. Brands want fast regional refreshes. I pair offset for core volume with digital for test lines and seasonal art. This blended plan lowers risk and keeps launch dates safe.

| Use case | Why offset | Notes |

|---|---|---|

| High-volume POP | Lowest unit cost, stable color | Aqueous coat for scuff |

| Brand Pantone | Spot inks, tight delta-E | Drawdowns, targets |

| Photo-heavy panels | Fine screens, sharp detail | 175–200 lpi common |

| Corrugated top sheets | Consistent laydown | Then mount and die-cut |

Conclusion

Offset still matters. I use it for volume, color, and cost. I add digital for speed and versions. This mix keeps launches on time and budgets safe.

Understanding CMYK is crucial for achieving accurate color reproduction in print, making this resource invaluable for designers. ↩

Learning about densitometers will enhance your knowledge of color measurement and quality control in the printing process. ↩

Understanding make-ready waste can help you optimize printing processes and reduce costs. ↩

Exploring variable data printing can enhance your marketing strategies by allowing for personalized content. ↩

Explore how sustainable displays can enhance brand image and meet consumer demand for eco-friendly products. ↩

Learn about the environmental benefits and print quality improvements of water-based inks for your projects. ↩