I once jammed three glossy brochures into my backpack, only to watch them crease and fade. The memory pushed me to hunt for tougher, lighter, smarter paper displays.

A paper display is a thin, flexible screen that mimics ordinary paper yet shows changing text or images while using almost no power.

That quick answer helps, but the magic behind these sheets runs deep. Stay with me; the tech might spark ideas for your next product stand or trade-show backdrop.

How does paper display work?

My early samples flickered in sunlight, so I dug into the basics, hoping to fix the glare and save my project.

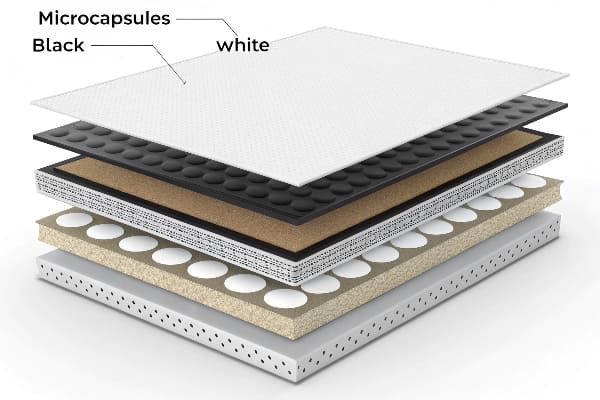

Paper displays rely on microcapsules or microcells that flip charged pigments when a small voltage is applied, creating readable images without backlight.

Core principles

Tiny capsules hold black and white particles. Electrodes on each side push or pull these particles. When white rises to the top, that pixel looks white. When black rises, it looks black. No current flows once the particles settle, so the image stays even if the battery is unplugged.

Power profile

| State | Typical Power Draw1 |

|---|---|

| Page refresh | 50–200 mW |

| Static display | <1 mW |

| Sleep | <0.1 mW |

Low power lets me pair a coin cell with a cardboard shelf talker for months. I can print brand colors on the border, then let the e-ink area swap prices or QR codes.

Advantages in retail

- Glare control2: Diffuse surface reads like paper under store lights.

- Thin profile3: Slides into a corrugated header without new tooling.

- Mount ease: Uses the same locking tabs I already design for foam cores.\

With these points clear, I fixed the sunlight issue by adding a matte overlay and shipped my first batch to a hunting-gear client.

What is a paper LED display?

Colleagues kept asking why I chose e-ink over the “paper LED” panels they saw on TikTok.

A paper LED display is an ultra-thin flexible sheet that embeds microscopic light-emitting diodes to form bright, full-color images while bending like paper.

Structure and materials

Paper LED4 sheets stack micro-LEDs onto plastic or metallic nanowire meshes, then laminate them between clear polymer layers thinner than a postcard.

Brightness versus power

| Technology | Peak Brightness5 | Typical Power | Color Range |

|---|---|---|---|

| Paper LED | 1000 cd/m² | High | 16.7 M |

| E-ink | Reflective | Very low | Limited |

Full color and video speed draw eyes in a big-box aisle, but they drain power fast. I once rigged a crossbow stand with a paper LED header. The looped hunting clip looked amazing, yet the battery pack needed daily swaps.

When I use paper LED

- Short campaigns: Grand openings or two-week promos.

- High ambient noise: Bright LEDs cut through neon and metal halide lamps.

- Dynamic storytelling6: Motion helps show how limbs fold on a compound bow.\

Still, for year-round end-caps I return to passive displays. That decision keeps maintenance low for my B2B clients who want to set and forget.

What is a paper screen?

“Paper screen” crops up in every sales call, and the phrase can confuse even seasoned buyers.

A paper screen is any display technology designed to look and feel like paper, covering e-ink, cholesteric LCD, and new reflective LCD hybrids.

Families of paper-like screens

| Type | Key Feature | Typical Use Case |

|---|---|---|

| Electrophoretic7 | Bistable, low power | e-readers, price tags |

| Cholesteric LCD8 | Color without filter | Kid books, greeting cards |

| Reflective LCD9 | Fast refresh | Smartwatches, signage |

My field tests

I glued cholesteric panels onto a folding dump bin for arrows. The colors popped, but the narrow viewing angle hurt side shoppers. Reflective LCD fixed that, yet added cost. Through trials, I map screen type to project goals: long dwell time equals e-ink; fast data means reflective LCD; novelty gifts lean on cholesteric.

Integration tips

- Cutout alignment: Leave 2 mm edge clearance so the flex cable folds clean.

- Heat limits: Keep lamination under 110 °C to protect plastic substrates.

- Mount options: Use double-sided PET tape rather than hot-glue to avoid warping.

Each run teaches me another constraint, which I feed into our CAD library for faster quoting. That reduces the back-and-forth that once annoyed buyers like David from Barnett Outdoors.

Are e-ink displays expensive?

Buyers often flinch at unit quotes, so I break down the math before they walk away.

E-ink displays cost more upfront than paper prints, but total ownership drops because they update content electronically, cut waste, and last for years.

Cost breakdown

| Expense Category | Print Posters (annual) | E-ink Panel10 (one-time) |

|---|---|---|

| Design revisions | $300 | $0 |

| Monthly reprints | $50 × 12 = $600 | $0 |

| Panel price | — | $45 |

| Battery swap yearly | — | $5 |

| Three-year total | $1,800 | $60 |

Payback lens

I tell clients to count every seasonal price change. A sporting-goods chain near Chicago refreshed crossbow promos six times last year. They spent more on courier fees than on my entire smart-shelf pilot. After eight months, the e-ink tags paid for themselves.

Hidden savings

- Labor11: Staff press a button to sync new prices.

- Waste: No piles of outdated foam boards.

- Brand consistency12: Firmware locks color profiles, ending shade drift.\

I admit, MOQ and lead time can bite small orders. Still, bulk buys drop panel cost below ten dollars. That fits my wholesale model, where repeat runs level the investment.

Conclusion

Paper displays blend print feel with digital brains, letting me build lighter, smarter, and greener point-of-sale tools that keep messages fresh without constant reprints.

Understanding the power draw of e-ink displays can help you optimize battery life and efficiency in your projects. ↩

Exploring glare control in e-ink displays can enhance your knowledge of display technology and improve user experience. ↩

Learning about the advantages of thin profiles can inspire innovative design solutions for your retail displays. ↩

Explore the benefits of Paper LED technology, including its unique features and applications in various settings. ↩

Understanding Peak Brightness is crucial for evaluating display performance and choosing the right technology for your needs. ↩

Learn how dynamic storytelling can enhance your marketing strategies and engage your audience more effectively. ↩

Discover the low power and bistable features of Electrophoretic technology, perfect for e-readers and price tags. ↩

Explore the benefits of Cholesteric LCD technology, especially its unique color capabilities without filters, ideal for creative applications. ↩

Learn about Reflective LCD technology, its fast refresh rates, and how it enhances user experience in devices like smartwatches. ↩

Explore the advantages of E-ink Panels, including cost savings and efficiency, to enhance your pricing strategy. ↩

Learn how to optimize labor costs in retail, making your pricing strategy more efficient and cost-effective. ↩

Discover the significance of brand consistency in retail pricing and how it can impact customer perception and loyalty. ↩