Creating custom packaging feels overwhelming when technical errors delay production. You just want your hunting gear displays to look perfect on the shelf without the hassle of rejected files.

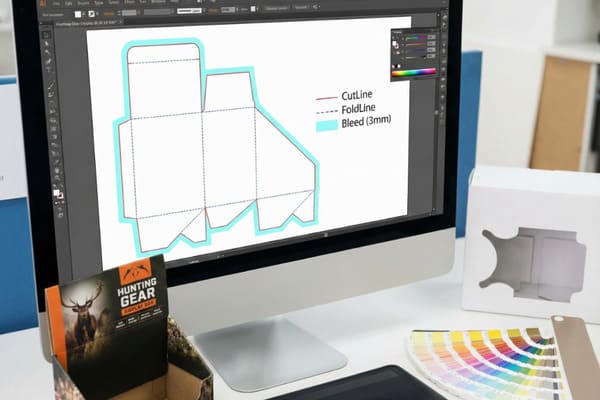

Preparing dielines requires setting a separate spot color layer for cut lines, ensuring bleed extends 3mm beyond trim, and setting fold lines to specific colors. Correct preparation ensures the die-cutting machine reads the vector paths accurately, preventing production errors and costly delays.

Let’s break down the technical steps to ensure your files fly through our prepress department smoothly.

How to set up dieline?

Starting a new project is stressful if you don’t know where to place the lines. A wrong setup means the structure collapses under your product’s weight.

To set up a dieline, open Adobe Illustrator and create a new layer named "Dieline." Use a distinct spot color (often 100% Magenta) for cut paths and a different spot color (like Cyan) for fold lines. Ensure these lines are vectors, not raster images.

The Structural Anatomy of Vector Paths

Setting up the dieline1 is not just about drawing a box; it is about engineering a structure that works. In Adobe Illustrator, the dieline must sit on a top layer, completely separate from your artwork layers. We often see clients mix the artwork and the cut lines, which causes the RIP software to print the cut lines on the final cardboard. That is a disaster for your brand image.

For heavy products like your hunting tools or crossbows, we usually recommend B-flute corrugated board2. This material has a thickness of about 3mm. Your dieline needs to account for this material allowance. If you draw a 90-degree fold without adding the material thickness variance, the box will not close properly, or it will bulge at the seams. When I look at files for Costco or Walmart displays, the structural precision is strict because they have no tolerance for failure.

You need to use 0.5pt or 1pt stroke weights for your lines. Do not use brush strokes or artistic effects. The cutting plotter needs a clean, simple vector path to follow. Also, you must distinguish your Cut lines (usually solid) from your Crease/Fold lines (dashed or a different color). If you treat them the same in the file, the machine might cut off a flap that was meant to fold. This ruins the structural integrity needed to hold 20 lbs of product. We also need to define perforation lines if you have tear-away sections for retail display headers.

| Line Type | Visual Style | Function | Spot Color Name Example |

|---|---|---|---|

| Cut Line3 | Solid Line | Cuts through the board completely. | Dieline_Cut (Magenta) |

| Crease/Fold | Dashed or Solid | Crushes the flute to allow folding. | Dieline_Fold (Cyan) |

| Perforation4 | Dotted Line | Creates a tear-away strip. | Dieline_Perf (Green) |

| Bleed Line | Solid Line (Outer) | Ensures art goes to the edge. | N/A (Guide layer) |

I know how frustrating it is when a prototype collapses because of bad line weights. That is why at PopDisplay, my structural design team runs a pre-flight check on every layer before we make a single sample. We fix these path errors for you so your display holds up.

What is a dieline in printing?

Many buyers confuse the dieline with the final print. This confusion leads to color issues and products that do not fit inside the box.

A dieline is the flattened, two-dimensional template that acts as a blueprint for the cutting die. It indicates exactly where the machine will cut, fold, glue, and perforate the cardboard material. It serves as the guide for both the graphic designer and the die-cutting machine.

Engineering the Blueprint for Physical Displays

Think of the dieline5 as the architectural blueprint for your packaging. In the printing industry, specifically for corrugated displays, this is the map that tells our digital cutters or traditional die-cutting molds what to do. It is not just a digital line on a screen; it represents a physical steel rule die. This is a large wooden board with sharp steel blades embedded in it. If the dieline in the file is off by even 1 or 2 millimeters, the physical die will be manufactured incorrectly.

For a large floor display holding expensive items, this tolerance is critical. The dieline defines the bleed zones as well. The artwork must extend beyond the cut line (the dieline) by at least 3mm (0.125 inches). This is because mechanical shifting happens during the lamination of the printed sheet onto the corrugated board. Without the dieline acting as the central reference point, you might end up with ugly white edges on your display.

It connects the creative art to the industrial manufacturing process. It tells us where the glue flaps are so we do not put varnish there. Glue does not stick well to UV varnish or lamination. If the dieline does not clearly mark the "glue free" zones, your display might fall apart in the store. It also shows the "safety zone6," which is usually 3mm to 5mm inside the cut line. You must keep important text and logos inside this safety zone so they do not get chopped off or folded over.

| Component | Description | Critical Requirement |

|---|---|---|

| Cut Path | The edge of the final product. | Must be a closed vector loop7. |

| Glue Flap | Area where adhesive is applied. | Must be free of ink and varnish. |

| Safety Zone | Safe area for text/logos. | Keep 3-5mm away from cut/fold. |

| Bleed Area8 | Art extension beyond cut. | Min 3mm (0.125") required. |

I have seen too many projects delayed because the artwork stopped exactly at the cut line. My team provides the correct dieline template right at the start. We ensure the bleed area is set correctly so your final display looks professional and clean.

What file format is preferred for a dieline template?

Sending the wrong file type stops production immediately. You cannot afford to miss a launch date because the file format was unreadable.

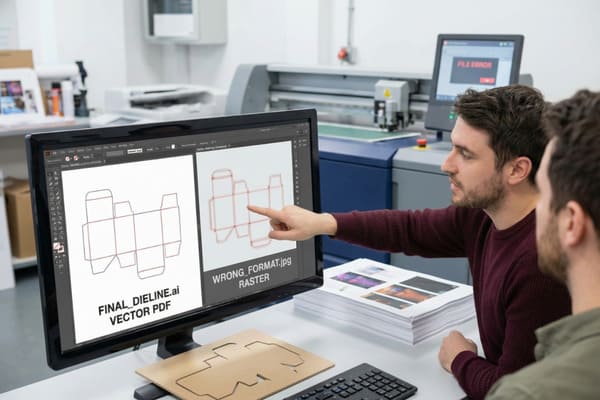

The industry standard file format for dieline templates is a vector PDF or an AI (Adobe Illustrator) file. These formats preserve mathematical vector paths required by cutting machines. Raster formats like JPEG or PNG are unusable because they lack the separate path data needed for die-cutting.

Vector Precision vs. Raster Limitations

We need files that speak the language of our machines. The preferred format is always a vector-based AI or PDF file9. Why? Because vector files use mathematical formulas to define lines and curves. This allows us to scale the design up or down without losing quality. If you send a JPEG, it is made of pixels. When the cutting machine software tries to read a JPEG, it sees a picture of a line, not the line itself. It cannot cut a picture.

Sometimes, structural designers work in CAD software like ArtiosCAD, so we might exchange ARD or DXF files for the structure itself. However, when you apply your graphics, you must bring that structure into Illustrator and save it as an AI or PDF. Do not flatten the layers. Keep the layers editable. If you flatten the file into a single background layer, we cannot separate the dieline from the graphics. This makes it impossible to trap colors or adjust the bleed.

For high-quality offset printing on cardboard, we need high-resolution images embedded10 in that AI file (at least 300 PPI), but the dieline itself must remain a vector path. If you are designing for a large pallet display, the file size can get huge. In this case, linked images in an Illustrator file are better than embedded ones, as long as you send the links folder along with the AI file. This ensures we can open the file quickly and check the dieline accuracy without lagging computers.

| File Extension | Format Type | Suitability for Dielines | Why? |

|---|---|---|---|

| .AI11 | Vector (Adobe) | Excellent | Native format, preserves layers. |

| .PDF12 | Vector (Portable) | Excellent | Universal, preserves vector paths. |

| .DXF | Vector (CAD) | Good (Structure only) | Used for CAD structure exchange. |

| .JPG / .PNG | Raster (Image) | Unusable | Cannot contain cut path data. |

We handle files from all over the world, and I often receive unusable JPEGs. My designers will convert your concepts into proper vector formats for free. We make sure the file works for our machines so you do not have to worry about technical conversions.

How to set dielines to overprint?

If your cut lines appear as white gaps in your artwork, the print is ruined. This common mistake creates unprofessional white outlines on your display.

To set dielines to overprint, select the dieline paths in Illustrator, open the "Attributes" panel, and check the box that says "Overprint Stroke." This ensures the artwork underneath acts as if the dieline isn’t there, preventing the software from knocking out the color below the line.

Preventing Knockouts and White Gaps

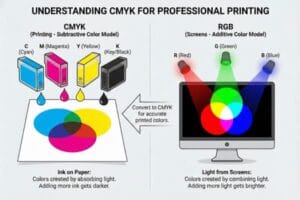

This is a specific technical setting that saves a lot of headaches. By default, design software like Illustrator uses a method called "knockout." This means if you place a red line on top of a blue background, the software removes the blue ink right under the red line. It does this to prevent colors from mixing. However, for a dieline, we do not want this. The dieline is a non-printing object. It is just a guide.

If you do not set it to "Overprint Stroke13," the RIP (Raster Image Processor) might think you want to print that line. Even if we turn off the dieline layer before printing, the "knockout" might have already happened in the processing stage, leaving a tiny white hairline gap where the line used to be. This looks terrible on a dark background. It makes the packaging look cheap.

Setting the stroke to Overprint tells the printer: "Print the background colors as if this line does not exist." It ensures continuous color coverage. This is vital for full-coverage designs often used in hunting gear packaging where dark camouflages and black tones are common. We check the separation preview in Acrobat14 to confirm this before plating. If we see the artwork disappear under the dieline when we toggle the dieline view, we know the overprint is not set correctly. Correcting this ensures your branding is seamless and the cardboard display looks high-end.

| Setting | Action on Background Ink | Visual Result | Recommendation |

|---|---|---|---|

| Knockout (Default)15 | Removes ink under the line. | Risk of white hairline gaps. | Avoid for dielines. |

| Overprint Stroke16 | Keeps ink under the line. | Continuous background color. | Required for dielines. |

| Multiply Mode | Blends colors. | Changes color appearance. | Not recommended for dielines. |

I verify the overprint settings personally on critical orders. We use automated pre-flight software that flags this error immediately. If you forget to check the box, my team catches it and fixes it to ensure your dark graphics print perfectly solid.

Conclusion

Dieline preparation is the foundation of structural success. Correct files ensure your displays arrive on time, look professional, and withstand the retail environment without failure.

Understanding dielines is crucial for creating effective packaging designs that ensure structural integrity and brand image. ↩

Explore the benefits of B-flute corrugated board for packaging, especially for heavy products, to enhance your design choices. ↩

Understanding Cut Lines is essential for precise cutting in design projects, ensuring your artwork is perfectly finished. ↩

Exploring Perforation techniques can enhance your design skills, especially for creating tear-away elements in print. ↩

Understanding dielines is crucial for effective packaging design, ensuring accuracy and quality in production. ↩

Exploring the concept of a safety zone helps prevent design errors, ensuring important elements are preserved in the final product. ↩

Understanding closed vector loops is essential for ensuring your designs meet production standards. ↩

Exploring the Bleed Area concept will help you create designs that look professional and polished. ↩

Explore this link to understand why vector files are essential for maintaining design quality and scalability. ↩

Learn about the significance of high-resolution images in ensuring quality in offset printing. ↩

Explore the benefits of .AI files for dielines, including layer preservation and native format advantages. ↩

Learn why .PDF files are preferred for dielines, focusing on their universal compatibility and vector path preservation. ↩

Understanding Overprint Stroke is crucial for ensuring seamless color coverage in your designs, especially for packaging. ↩

Learning to use the separation preview in Acrobat can help you avoid costly printing errors and ensure high-quality results. ↩

Exploring Knockout Default will help you avoid common pitfalls like white hairline gaps in your printed materials. ↩

Understanding Overprint Stroke is crucial for ensuring consistent color in your designs, especially for dielines. ↩