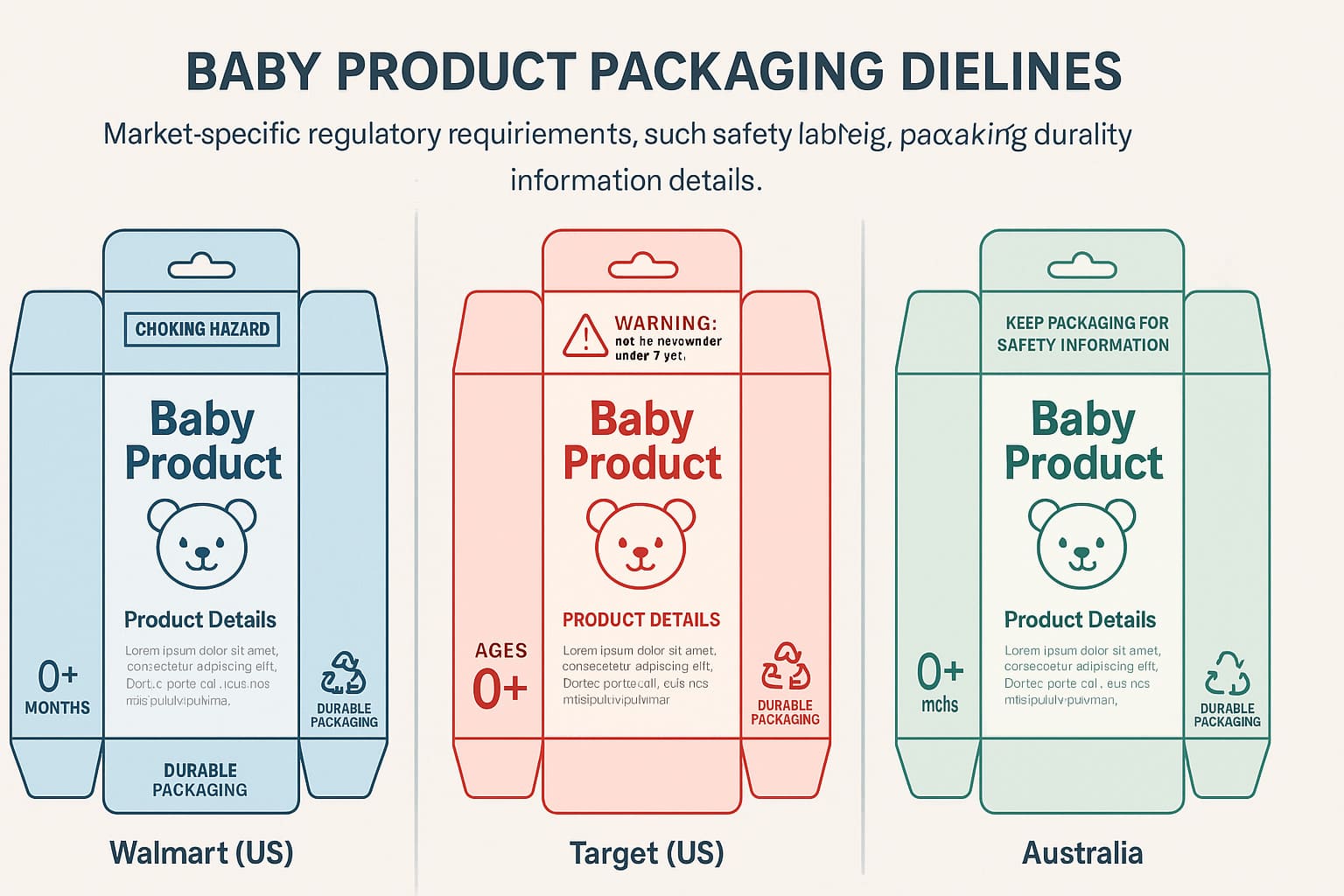

Designing separate packaging for the US and Australia is a logistical nightmare that doubles tooling costs and complicates inventory. You need a single, rock-solid strategy that satisfies Walmart's strict compliance teams and Australia's rigorous safety standards without destroying margins.

To create a universal packaging dieline compliant with global retail standards, manufacturers must standardize the following structural elements:

- Metric-Imperial Hybrid Sizing: Engineering base dimensions to module efficiently onto both GMA (48×40 in) and International (1165×1165 mm) pallets.

- Safety-First Edges: Utilizing wave-cut oscillating blades to eliminate sharp paper edges on consumer-facing areas.

- Dual-Compliance Material: Sourcing FSC-certified kraft linerboard that meets strictly regulated global safety standards.

Managing two different supply chains for the same baby bottle or toy is a waste of money. Let's look at how to merge them.

Baby Aisle Essentials: How to Create a Universal Dieline for Walmart, Target, and Australian Retailers?

If you send a generic dieline to a major retailer, their compliance officer will reject it before it even hits the shelf.

To design a universal dieline effectively for high-volume retail environments, brands should prioritize these standardized safety and structural protocols:

- Standardized Footprints: Adopting base dimensions (e.g., 24×20 inches / 60×50 cm) that maximize pallet utilization across different regions.

- Integrated Safety Features: Engineering rolled edges or safety folds to prevent consumer injury during product interaction.

- Global Material Grades: Specifying 32ECT (Edge Crush Test) B-Flute as the minimum strength baseline for retail durability.

The Structural Anatomy of Safe Baby Product Dielines

I often see clients try to save money by using a "standard" knife mold they found online. It's a disaster waiting to happen. In the baby aisle, the stakes are incredibly high because the end-user is a child or a tired parent. A sharp cardboard edge that cuts a finger isn't just a nuisance; in North American markets, it's a lawsuit, and in markets like Australia, it triggers an immediate recall.

We solve this with the Safety Edge Protocol1. On our ArtiosCAD software, we don't just draw straight cut lines. We program "Wave Cut" or "Scalloped" blades for any accessible edge of the display. This microscopically serrated edge feels soft to the touch, unlike the razor-sharp straight cut of standard corrugated board. I had a client last year who ignored this advice for a pacifier display to save $300 on new tooling. The retailer's safety audit flagged it immediately, and we had to manually tape the edges of 5,000 units in the warehouse. It was a nightmare I never want to repeat.

Furthermore, we have to tackle the Pre-press Bottleneck2. Clients frequently send artwork on a JPG or a PDF with no bleed, thinking it fits the dieline. It never does. We provide the "Empty Canvas" template in AI format before you design. This ensures that when we fold that heavy-duty 32ECT (Edge Crush Test) board, the artwork doesn't crack at the corners. For baby products, we also use a specific "Anti-Crack" film lamination. Shipping from a humid factory in Shenzhen to a dry warehouse in Nevada or the Australian Outback causes paper to dry out and split. This laminate stretches, keeping the branding pristine even when the board flexes. We often use a 44ECT "Virgin Kraft" liner for the main load-bearing walls to ensure the unit doesn't buckle under the weight of heavy liquid products like baby lotion or wet wipes.

| Feature | Standard Generic Dieline | Universal Baby-Safe Dieline |

|---|---|---|

| Edge Finish | Straight Cut (Sharp/Risk) | Wave/Safety Cut (Soft/Safe) |

| Material Grade | 32ECT Recycled Testliner | 44ECT Virgin Kraft3 (High Tensile) |

| Lamination | Standard Gloss PP | Anti-Crack Soft Touch Matte |

| Corner Design | Simple Score | Double-Wall Rolled Edge |

| Audit Status | High Risk of Rejection | Safety Audit Compliant |

When you request a quote, I automatically send you the correct dieline template tailored for the baby category. I do not let you start designing on a napkin sketch because I know it will fail the safety audit later.

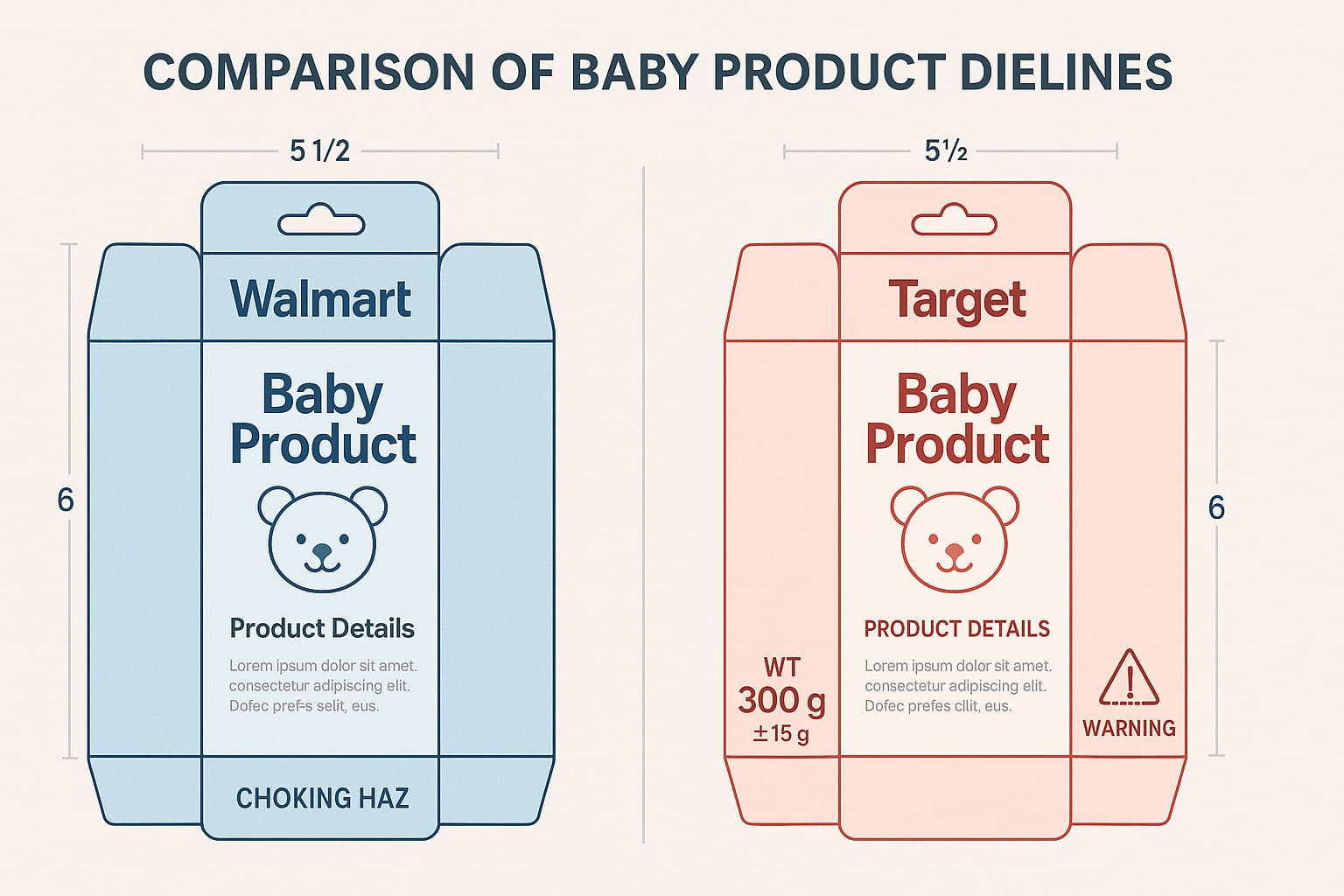

What Are the Critical Dieline Specs for Baby Aisle Products in Walmart and Target's US Markets?

Retailer "Style Guides" are not suggestions; they are strict laws. Missing a dimension by half an inch gets your product kicked out.

The critical dieline specifications for baby aisle products in mass-market retail environments include:

- Total Height Limits: Restricting floor displays to strictly 60 inches (152 cm) including the header to maintain store sightlines.

- Price Channel Height: Dedicating exactly 1.25 inches (3.17 cm) on shelf lips for standard price tags and scanner rails.

- Non-Toxic Certification: Mandating heavy-metal-free inks compliant with strict consumer safety regulations.

Strategic Analysis of Retailer-Specific Safety Mandates

Major retailers don't play around with chemical safety in the baby section. The most critical, yet often overlooked, specification is the Baby Safe Ink Standard4. Standard industrial inks often contain volatile solvents or heavy metals. If a teething baby touches your display and then puts their hand in their mouth, you have a major liability issue.

I strictly use Soy-Based Inks5 and water-based varnishes for these clients. We had a situation where a buyer wanted a metallic silver finish using Pantone 877C. The problem is, standard metallic inks use metal flakes that can be flagged in safety testing. I refused to print it. Instead, we used "Cold Foil" stamping which is plastic-free and stable. It cost 10% more, but it passed the CPSIA (Consumer Product Safety Improvement Act)6 testing with zero issues.

Another huge pain point is the ADA Reach Range7. Designing for the US market means complying with the Americans with Disabilities Act. If you place the main product shelf too high or too low, you risk retailer rejection for accessibility reasons. We design the primary "dispensing zone" to sit between 15 inches (38 cm) and 48 inches (122 cm) from the floor. This ensures that a parent in a wheelchair can easily reach the diapers or wipes. Many designers focus on the "Eye Level" for standing shoppers but forget the "Reach Level" for everyone else. We bake these dimensions into the CAD file from day one. I also enforce the "1.25-inch Rule" for price channels. If your shelf lip is 1 inch, the store's standard price tag sticker hangs off the edge, collects dust, and eventually falls off. We build the structure to naturally accept the standard tag size without needing scotch tape.

| Specification | Standard Retail Requirement | Strict Baby Aisle Requirement | My Factory Standard |

|---|---|---|---|

| Max Height | 60" (152 cm) | Varies, strict on Sightlines | 58" (147 cm) (Safe Zone) |

| Ink Safety | Standard Industrial | Restricted Substances List (RSL) | Soy-Based / Heavy Metal Free |

| Price Holder | Adhesive Strip Preferred | Integrated Structure | Integrated 1.25" Fold |

| Structure | Standard Strength | Must withstand cleaning | Mop Guard + Hidden Support |

I keep a database of these specs. If you tell me this is for a specific retailer, I automatically adjust the shelf lip height to match their specific scanner rails so you don't have to guess.

Dual-Market Success: How to Optimize Packaging Design for US and Australian Baby Product Compliance?

Shipping mostly air across the Pacific is the fastest way to kill your profit margin.

To optimize packaging design for dual-market compliance and logistics efficiency, manufacturers should implement these supply chain strategies:

- Container Optimization: Adjusting carton dimensions to fit both 40HQ and 20ft containers efficiently.

- Climate-Resistant Materials: Using high-grade Kraft liner to withstand ocean humidity and temperature fluctuations.

- PFAS-Free Coatings: Applying water-based barriers to meet emerging environmental laws in global regions.

Logistics Engineering and Material Science

The biggest friction point between the US and Australia is the pallet. The US uses the 48×40 inch (122×102 cm) GMA Pallet8, while Australia often uses the 1165×1165 mm CHEP Pallet. If you design a display footprint that is exactly 24×20 inches (61×51 cm), it fits perfectly (4 units) on a US pallet. But on an Australian pallet, you leave massive gaps, leading to load shifting.

My approach is "Nested Packing9". We don't ship these displays assembled if we can avoid it. We design the head card and internal trays to fit inside the hollow base of the dump bin or floor stand. It's like a Russian Matryoshka doll. By doing this, we reduce the "Volumetric Weight" significantly. I recently redesigned a shipper for a baby toy brand; by changing the header to a bi-fold design, we increased the unit count per container by 22%. That saved them about $4,000 in freight for one shipment.

We also have to talk about PFAS-Free Mandates. As of 2025, many US states (like California and Maine) and increasingly Australian regulators are banning "forever chemicals" (PFAS) in packaging. Traditional water-resistant coatings—essential for the "Mop Guard" to prevent soggy bottoms—often contain these. I've switched my entire line to a verified PFAS-Free Water-Based Coating10. It provides the same moisture resistance for those wet supermarket floors but keeps you legal. We verify this with the Cobb Test11 (measuring water absorption) in our lab. Standard recycled board acts like a sponge, absorbing water instantly. Our treated Virgin Kraft board beads water off like a waxed car, ensuring the display doesn't collapse into a mushy pile after the floor cleaners come through.

| Optimization Strategy | Traditional Method | My Dual-Market Method | Benefit |

|---|---|---|---|

| Pallet Fit | Fixed rigid dimensions | Modular footprint | Fits US & AU Pallets |

| Moisture Barrier | Plastic Lamination (PE) | PFAS-Free Varnish | Legal Compliance |

| Packing Style | Semi-Assembled (Air) | Nested / Flat-Pack | 20-40% Freight Savings |

| Material Strength | Recycled Testliner | Virgin Kraft Liner | Survives Ocean Transit |

I calculate the container load plan before we cut the sample. I will tell you exactly how many cents per unit the freight will cost, so there are no surprises when the invoice lands.

Avoid Costly Delays: What Are Walmart & Target's Dieline Requirements for Baby Accessories?

Nothing stops a product launch faster than a barcode that won't scan or a box that violates a hidden rule.

To avoid costly supply chain delays, dieline requirements for retail accessories must include specific technical mandates:

- Barcode Placement: Positioning UCC-128 labels on both long and short sides, strictly avoiding fold lines.

- Overprint Settings: Ensuring dielines are set to 'overprint'in the artwork file to prevent white gaps.

- Quiet Zones: Maintaining a minimum 0.25-inch (6 mm) white space around all scannable codes.

Pre-Press Technicalities and Compliance Traps

The "Overprint12" error is a classic rookie mistake that ruins thousands of boxes. In Adobe Illustrator, if your designer leaves the cut line as a standard stroke, it "knocks out" the artwork behind it. If the die-cutter shifts even 0.5mm (0.02 in) during production—which happens mechanically—you get an ugly white hairline on every edge of your premium baby box. It looks cheap.

I run a Preflight Check13 using PitStop Pro on every single file you send me. We force all structural lines to "Overprint" automatically. But beyond print, we have to look at the Repacking Fee Prevention14. Distribution Centers (DCs) are ruthless. If your shipping carton barcode is wrapped around a corner or placed too low, the automated scanners can't read it. The retailer will charge you a "Vendor Compliance Fine" and a repacking fee.

I know the rule: The label must be at least 1.25 inches (3.2 cm) from the bottom edge and clearly visible on the longest side. I don't trust manual workers to guess this. We use templates and robotic placement aids to ensure every sticker is in the exact "Strike Zone." I had a client get hit with a $5,000 fine from a US retailer because their previous supplier put the label over the tape seam. We don't make those mistakes. We also verify the ANSI Grade15 of the barcode print. We aim for a Grade A or B. If you print a barcode on raw corrugated without a white background, the "Dot Gain" (ink spreading) creates a blurry code that scans as a fail. We always print a high-opacity white patch behind the code to ensure crisp contrast.

| Error Type | The Mistake | The Consequence | My Prevention Protocol |

|---|---|---|---|

| Barcode | Placed on fold/corner | Unscannable / Fines | Template-locked placement |

| Artwork | Knockout Cut Lines | White Edges (Ugly) | Auto-Overprint Check |

| Labeling | Missing Country of Origin | Customs Seizure | Printed "Made in China" |

| Adhesive | Tape over Barcode | Read Error | Tape-free label zones |

I act as your final gatekeeper. If I see a barcode in a danger zone on your artwork, I will stop the press and email you. I'd rather delay production by one day than let you pay a fine later.

Designing a Floor-Stand Sidekick: How to Align with US Retailer Standards and Australian Regulations?

Sidekicks are great for impulse buys, but they are notoriously unstable if designed poorly.

To align with global retailer standards for floor-stand sidekicks, designers must incorporate these stability features:

- Universal Brackets: Using metal S-clips compatible with standard Gondola and wire shelving systems.

- Trapezoidal Spines: Tapering the back panel to shift the center of gravity toward the shelf fixture.

- Standardized Dimensions: Capping the unit width to fit standard end-cap wings without obstruction.

Gravity Physics and Fixture Compatibility

The "Parasitic Weight" issue is real. A Sidekick (or Power Wing) hangs off the side of a main shelf. If you design it like a regular box, the center of gravity is too far forward. As soon as a customer pulls a heavy bottle of baby lotion, the torque rips the cardboard hook, and the whole thing crashes to the floor. This is basic physics (Moment = Force x Distance), but designers ignore it constantly.

I solve this with the Trapezoidal Back Panel16. We taper the back structure so it's wider at the mount point and the spine is double-reinforced corrugated board. This keeps the weight tight against the gondola wall. But the real secret is the Universal Bracket17. Cardboard tabs are weak. I insist on installing a metal bracket or a reinforced plastic "S-Clip."

US shelves (Lozier/Madix) and Australian shelves often have different slotting. A standard fixed hook won't work for both. I use a multi-fit bracket system that locks securely onto 95% of global retail fixtures. Plus, we adhere to the Height Standardization18 rule. We keep the body to exactly 48 inches (122 cm) high. This fits the standard US end-cap spacing perfectly, leaving room for the mop guard at the bottom and the header clip at the top. We also reinforce the shelves with a "Rolled Front Lip19". Instead of a simple single cut, we fold the front of the shelf over. This creates a beam structure that resists sagging. I once saw a competitor's display where the shelves bowed after two days of humidity, dumping glass baby food jars onto the floor. My shelves don't bow.

| Component | Cheap Method | My Compliant Method | Why? |

|---|---|---|---|

| Mounting | Cardboard Tab | Metal/Plastic Universal Clip | Won't tear under load |

| Geometry | Square Box | Tapered / Trapezoid | Reduces forward torque |

| Width | Random | Max 14" (35 cm) | Fits standard End-Caps |

| Shelf Strength | Single Wall | Double-Fold / Metal Bar | Prevents "Tier Sag" |

I recommend spending the extra 40 cents on the metal hardware. It guarantees your display stays hanging up until the products are sold, rather than ending up in the compactor in week one.

Conclusion

Designing for dual markets is tough, but with the right structural engineering, you can satisfy both Walmart and Australian regulators. Would you like me to send you a [Free Structural 3D Rendering] of your new baby product display so you can check the safety edges yourself?

Explore this link to understand how the Safety Edge Protocol enhances safety in baby product packaging. ↩

Learn about solutions to the Pre-press Bottleneck to streamline your packaging design process. ↩

Find out why 44ECT Virgin Kraft is preferred for heavy-duty packaging in baby products. ↩

Understanding the Baby Safe Ink Standard is crucial for ensuring safety in products for infants, protecting both health and compliance. ↩

Explore the advantages of Soy-Based Inks, including environmental benefits and safety for children's products. ↩

Learn about the CPSIA to understand safety regulations that protect consumers, especially in children's products. ↩

Discover the significance of the ADA Reach Range in creating accessible designs that cater to all consumers. ↩

Understanding the GMA Pallet's specifications can help optimize logistics and shipping processes. ↩

Learn how Nested Packing can significantly reduce shipping costs and improve space utilization. ↩

Exploring PFAS-Free coatings can enhance your packaging sustainability and compliance with regulations. ↩

Discover the importance of the Cobb Test in ensuring packaging durability and moisture resistance. ↩

Explore the concept of Overprint to enhance your design skills and avoid common printing mistakes. ↩

Understanding Preflight Checks can help you avoid costly printing errors and ensure high-quality outputs. ↩

Learn effective strategies to avoid repacking fees and save money on shipping costs. ↩

Discover the importance of ANSI Grade for barcodes to ensure they are scannable and compliant. ↩

Explore this link to understand how a Trapezoidal Back Panel enhances stability and weight distribution in retail displays. ↩

Learn about the advantages of using a Universal Bracket for securing displays and preventing damage. ↩

Discover the significance of Height Standardization in optimizing retail space and ensuring compliance. ↩

Find out how a Rolled Front Lip can enhance shelf durability and prevent sagging in retail environments. ↩