I meet the same problem many brands face. One display must fit two markets. Rework burns time and money. I use one master dieline system and fix it for both.

Build one master dieline in vector CAD, keep dual units (mm and inches), reserve GS1 barcode zones for EAN-13 and UPC-A, map to AU 1165×1165 mm and US 48×40″ pallets, set bleed/safety/score allowances, and validate by a physical prototype.

I sell B2B displays, so I write from the factory floor. I design, test, and ship. My team supports fast samples, free tweaks, and strength tests. I share my field notes below.

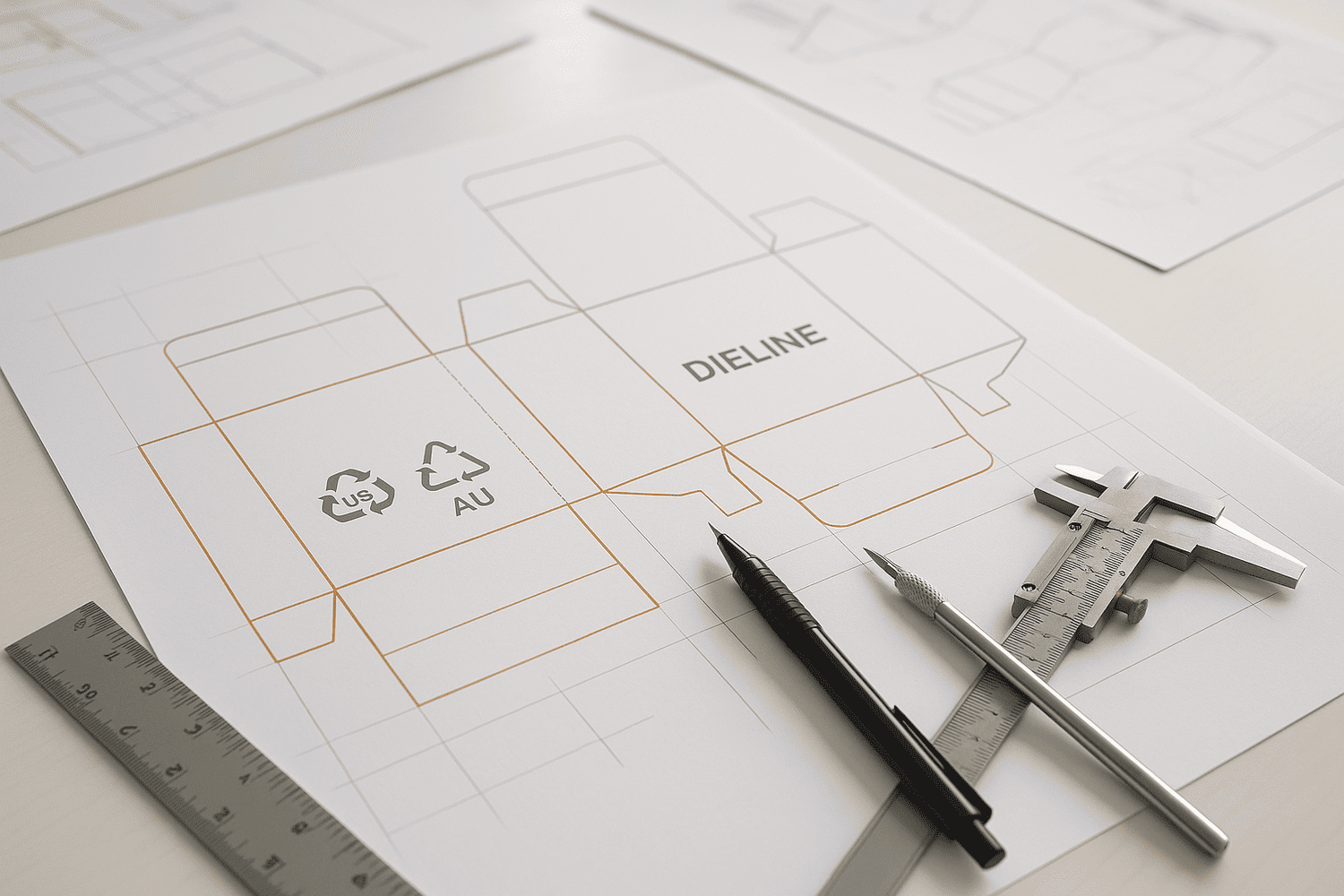

How do you create dielines?

I start with where the display will live. I list retailer rules, pallet size, product weight, and barcode type. Then I design to one master.

I define product and retail limits, choose board and flute, set cut and crease layers, keep bleed and safety, plan UPC/EAN zones, palletize for AU and US, build a sample, and stress-test before print.

My step-by-step build

I keep steps simple and visible for my team and for buyers who need speed. I write every value in mm and inches to avoid errors. I also lock barcode quiet zones because US buyers use UPC-A, while many AU buyers use EAN-13. I always palletize early1. US warehouses expect 48×40″ footprints, while Australian DCs often plan 1165×1165 mm (CHEP). I keep both maps in the master file, and I tag them. I also plan strength from the start. Hunting gear and outdoor tools add weight, so I add larger glue flaps and wider feet on floor displays. I test with drop and vibe tests2 because transport hurts weak feet first. I run a quick digital print sample to confirm color and text sizes for older shoppers. I do a small run to confirm assembly time on the shop floor. I keep the dieline clean, so the store staff reads it in seconds.

| Step | What I Do | Why It Matters (AU + US) |

|---|---|---|

| 1 | Define product size/weight3 | Prevent collapse and tilt |

| 2 | Lock retail rules | Match Walmart/Target and Coles/Woolworths |

| 3 | Choose board & flute | Balance cost, print, strength |

| 4 | Set cut/crease/bleed | Clean print and fast make-ready |

| 5 | Reserve barcode zones | UPC-A (US) / EAN-13 (AU) quiet areas |

| 6 | Map pallets | US 48×40″ / AU 1165×1165 mm fit |

| 7 | Prototype & test4 | Catch faults before mass print |

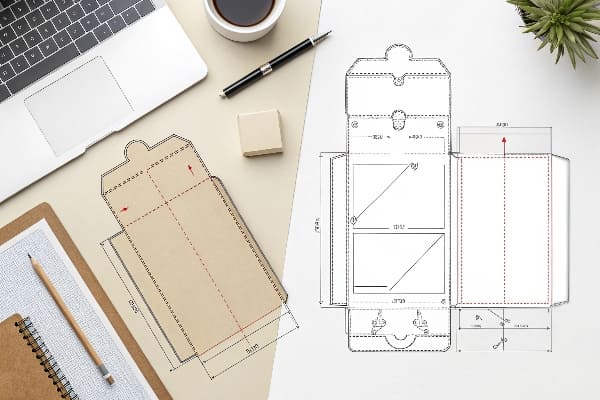

What are the guidelines for dieline?

I write rules before I draw. Rules save hours later. I set clear layers, safe areas, and label needs for both markets.

Use clear layer names, dual units, 3–5 mm bleed, 5–8 mm safety, barcode quiet zones, flute/grain notes, pallet maps, glue zones, and assembly arrows; validate with a sample and a drop test.

Cross-market rules I rely on

I keep guidelines that my designers and press crews can follow with no guesswork. I keep bleed at 3–5 mm, and I increase to 6 mm on heavy corrugated where registration drift is higher. I mark safety at 5–8 mm from cuts and 10 mm from crash-lock bottoms. I note flute direction to support vertical load. I keep the barcode area unprinted5 for the quiet zone. I write both UPC-A and EAN-13 options into the art board, so the brand chooses late without a re-draw. I add pallet and aisle constraints, because US warehouse aisles and AU DCs handle different turns and stack patterns. I add simple assembly arrows; store staff must build fast. I include recycling marks6 that fit each market policy when requested. I check color with a low-cost digital proof. I run a one-unit transit test for corners and feet. I sign off only after the prototype passes.

| Topic | US | Australia | My Rule |

|---|---|---|---|

| Barcode | UPC-A | EAN-13 (GS1)7 | Keep both placeholders |

| Pallet base | 48×40″ | 1165×1165 mm | Map both in file |

| Units | Inches common | Millimeters common | Show both always |

| Bleed | 3–5 mm | 3–5 mm | Raise to 6 mm on corrugated8 |

| Safety | 5–8 mm | 5–8 mm | 10 mm near locks |

| Flute/Grain | Note for load | Note for load | Vertical flute for columns |

| Labels | Retailer-specific | Retailer-specific | Keep a free compliance panel |

What is a dieline structure?

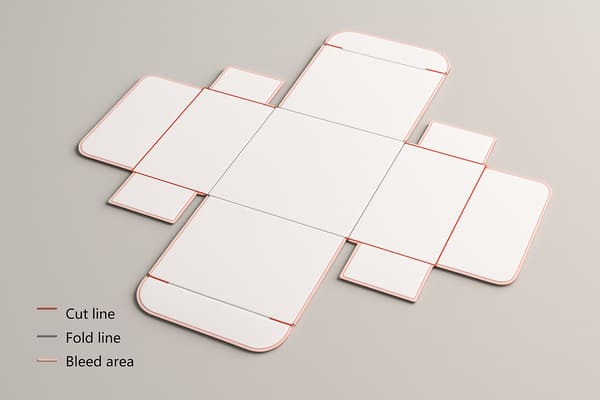

A dieline is not only a shape. It is a set of layers. Layers tell knives, creasers, printers, and packers what to do.

A dieline structure is a layered file that separates cut, crease, perforation, glue, print, and notes, so design, tooling, and production read the same plan without guesswork.

Layers that never fail me

I keep strict colors and line types. Cut lines stay as solid magenta and overprint off in art proofs. Crease lines use dashed cyan. Perforations use dot-dash. Glue zones use a soft tint fill. Print-only graphics live on their own layer and never touch the tooling layers. I add an assembly layer with arrows and numbers for store staff. I include a compliance layer9 with empty panels for ARL or other recycling marks in AU and for US retail notes. I keep a palletization layer10 with outlines for both markets. I lock a measurements layer with dual units. I include a notes layer for board grade and finish, like E flute, single-wall, and matte AQ varnish. This structure speeds handoff. Prepress can trap art without moving cut paths. Tooling can export DXF for the die maker. Production can check glue positions at a glance.

| Layer | Line/Fill | Purpose | Notes |

|---|---|---|---|

| Cut | Solid | Knife path11 | Do not overprint |

| Crease | Dashed | Score path | Add score allowance |

| Perf | Dot-dash | Tear path | Control tear strength |

| Glue | Tint fill | Adhesive zones12 | Add overlap sizes |

| CMYK/RGB | Graphics | Keep away from knife | |

| Assembly | Arrows/numbers | Build steps | Aid store teams |

| Compliance | Empty boxes | Labels | For AU/US needs |

| Pallet Map | Outlines | Stacking | US and AU footprints |

| Dimensions | Dual units | Checks | No scale errors |

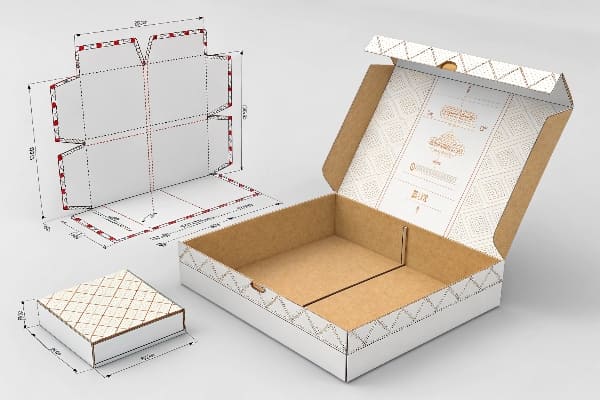

What is the difference between template and dieline?

People mix these words. That causes costly mistakes. I keep them separate in my files and in my talks with buyers.

A template is a starting layout for fit and brand; a dieline is the final, tool-ready, layered path set for cutting, creasing, and glue. Templates guide; dielines manufacture.

How I explain it to teams and buyers

I use template13s in early talks. A template shows outer size, rough panels, and where key art might sit. I use it to collect feedback and to speed design sign-off. A template is flexible and fast. I never send a template to a die maker. A dieline14 is different. A dieline is precise and locked. It has cut, crease, perf, and glue layers. It includes barcode zones, pallet maps, and notes. It is tool-ready. I move from template to dieline only after the brand approves the 3D render and the sample. I learned this the hard way on a heavy floor display for an outdoor line. I rushed a template to tooling. The feet tore in transit because there was no extra score allowance. I rebuilt with a true dieline, added bigger feet and different flute direction, and the display passed drop tests. Since then, I keep the names clear in emails, file names, and quotes.

| Item | Template | Dieline |

|---|---|---|

| Purpose | Concept and fit | Manufacturing and tooling15 |

| Layers | Minimal | Full cut/crease/perf/glue/notes |

| Accuracy | Approximate | Exact with tolerances |

| File name | *_template.ai | *_dieline.ai (or .dxf for die) |

| Audience | Brand/marketing | Prepress/tooling/production16 |

| Change rate | High | Low (controlled) |

Conclusion

One master dieline, two markets. I design with dual units, barcode options, pallet maps, and strict layers. I prototype early. I protect time, cost, and trust.

Exploring this resource will provide insights into optimizing logistics and improving efficiency in your supply chain. ↩

Understanding these tests can help ensure your products withstand transport, enhancing durability and customer satisfaction. ↩

Understanding product size and weight is crucial for ensuring packaging integrity and preventing damage during transport. ↩

Prototyping and testing help identify potential issues early, saving time and resources in the long run. ↩

Understanding the significance of an unprinted barcode area can enhance your packaging design, ensuring better scanning and compliance. ↩

Exploring the role of recycling marks can help you align with market policies and promote sustainability in your packaging. ↩

Explore this link to understand the significance and applications of EAN-13 barcodes in retail and logistics. ↩

Discover how corrugated materials enhance packaging durability and sustainability, making them ideal for various applications. ↩

Understanding compliance layers is crucial for ensuring your designs meet industry standards and regulations. ↩

Exploring palletization layers can enhance your packaging efficiency and optimize shipping processes. ↩

Understanding knife paths is crucial for precise cutting in design, ensuring your projects are executed flawlessly. ↩

Exploring adhesive zones helps in optimizing packaging efficiency and ensuring strong bonds in your designs. ↩

Exploring the use of templates can enhance your design workflow, making it more efficient and effective. ↩

Understanding dielines is crucial for ensuring accurate and effective packaging design, making this resource invaluable. ↩

Explore this link to gain insights into effective strategies and techniques in manufacturing and tooling. ↩

This resource will help you understand the critical functions of prepress and tooling in ensuring quality production. ↩