I see many brands pick glassine because it looks clean. Teams ask how it is made. Confusion creates wrong specs and delays. I use a simple process view to fix this.

Glassine paper is made from refined wood pulp that is beaten to high hydration, formed into a wet web, then supercalendered under heat and high pressure to collapse pores. This creates a dense, smooth, translucent, grease-resistant sheet without wax or plastic coating.

I work in cardboard displays, so I test materials often. I test paper in real shipping and in store light. I share what works and what fails. You can use these notes to avoid trial and error.

Is glassine paper environmentally friendly?

Many buyers want a clear look but fear hidden plastic. Teams need facts for audits. I break down what is safe, what is not, and what to ask suppliers.

Clean glassine is recyclable with paper streams in many regions, is plastic-free, and is biodegradable and compostable under industrial conditions; contamination from food oil, inks, or adhesives can reduce recyclability, so I design liners and labels to keep it clean.

What makes glassine "green," and where it fails

I use glassine sleeves for instruction cards and SKU tags inside pallet and floor displays. The sheet comes from cellulose only, so the base is plastic-free1. Mills beat the pulp longer, then supercalender the sheet. This step uses energy, so I ask for mill energy data and FSC or PEFC fiber. Recyclers accept clean glassine with mixed paper. Oil or heavy adhesive makes problems. My team now adds a peelable paper label on the sleeve instead of permanent glue. We also print with water-based inks and cure well, so rub-off is low. I ask suppliers for CMYK ink MSDS, and I avoid UV varnish near edges. My pack plan keeps glassine away from food contact unless the mill shares migration data. I keep claims simple and clear in specs: "Plastic-free, recyclable where facilities exist." This line helps brand reviews and reduces risk.

| Factor | Glassine | My display practice |

|---|---|---|

| Fiber | 100% cellulose | Ask for FSC/PEFC |

| Additives | No wax, no plastic | Avoid heavy coatings |

| Recyclability | If clean | Keep oil/adhesive off |

| Compostability | Industrial | Do not over-claim |

Can you print on glassine paper at home?

Designers love the frosted look for labels and envelopes. Home printing sounds easy. Real jobs smear and jam. I show what setups work and what to avoid.

Yes, you can print on glassine at home, but results vary: laser printers bond better; inkjet often smears because the sheet is dense and non-porous; use light coverage, slow feed, and let prints cure flat. Test before a big batch.

Practical setups that saved my deadlines

I print short-run mockups for buyers on tight clocks. My laser printer2 works best because toner fuses to the surface. I set a "thick paper" mode, low speed, and straight-through path. I keep coverage under 180% total ink to stop curl. Inkjet can work with pigment inks, but dye inks smear fast. I pre-warm sheets under a desk lamp, then print one sheet at a time. I place pages under books for ten minutes to stay flat. Stamp inks also help. I use solvent-based stamp pads3 for logos on glassine bags when I need a hand finish. I avoid heavy solids near edges, because fuser rollers can mark them. When I ship samples to the United States or Canada, I sandwich the prints between chipboard panels. My notes also record lot numbers, because gloss and slip can change by mill. Small habits stop rework and keep buyer trust.

| Home Method | Works? | Tips |

|---|---|---|

| Laser print | Good | Thick-paper mode; straight path |

| Inkjet (pigment) | Fair | Light coverage; long dry time |

| Inkjet (dye) | Poor | Smears; avoid |

| Rubber stamp | Good | Solvent pad; quick hits |

| Foil/toner | Ok | Clean, hot, light pressure |

What is an alternative to glassine paper?

Sometimes supply is tight or price moves. I pick substitutes that keep the look or the barrier. I match the need first, then I pick the sheet.

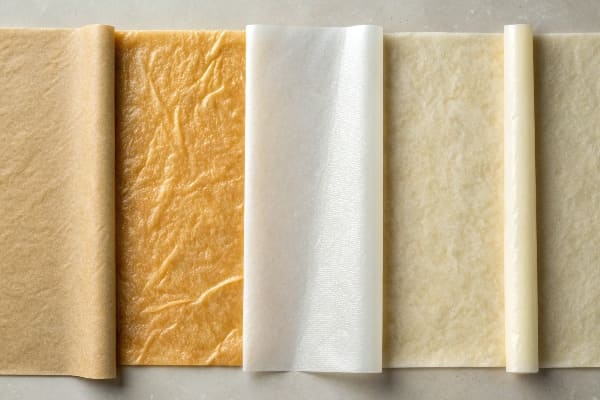

Common substitutes include greaseproof paper, translucent vellum, baking parchment, cellulose film (true cellophane), and recyclable paper liners; each swap trades off translucency, grease resistance, printability, and cost, so I choose by the exact display task.

How I choose the right stand-in

I start with the job. If a client wants a window with a soft frost, I use vellum. Vellum prints well and costs less, but it blocks grease less than glassine. If the job holds oily parts, I choose greaseproof paper4 with higher kit ratings. It is not as smooth, but it holds up in transit. For a high-clarity window, I use true cellulose film5. This film is plastic-free and home-compostable in some regions. It dies under strong folds, so I keep bends wide. For hot bakery tie-ins, I use baking parchment. The silicone coat handles heat, but it is less printable. When the client wants a premium feel for tags, I choose smooth wood-free with a satin varnish and accept lower barrier. I log failures too. Waxed paper looks similar in photos but blocks heat sealing and causes label lift. That mistake cost me a week once, so I set a material ID step in our SOP.

| Need | Best Substitute | Trade-off |

|---|---|---|

| Frosted look labels | Vellum | Lower grease barrier |

| Oily parts pouch | Greaseproof | Rougher surface |

| Clear window | Cellulose film | Brittle folds |

| Oven tie-in | Baking parchment | Harder to print |

| Budget sleeve | Uncoated wood-free + varnish | Minimal barrier |

What is the difference between butter paper and glassine paper?

Buyers often say "butter paper" on calls. Teams mean different things by that term. I push for clear names to stop wrong specs and reprints.

Butter paper often means baking parchment or waxed/greaseproof paper by region, while glassine is supercalendered, uncoated, and translucent; glassine resists grease by density, not by wax or silicone coating, so print and heat behavior differ.

Clear terms that protect budgets

I sell to the United States, Canada, the United Kingdom, and Australia. I hear "butter paper" used for wax paper in one place and baking parchment in another. Wax paper has a paraffin coat. It blocks grease well but melts near heat. It is not oven-safe. Baking parchment has a silicone coat. It is oven-safe and releases food and stickers cleanly. Greaseproof6 paper is dense but not calendered as much as glassine. Glassine has no wax or silicone. It gets grease resistance from high fiber bonding and low porosity. These facts shape print and pack. Toner fuses well on glassine. Toner can bead on silicone parchment. Hot-melt glue sticks better to greaseproof than to wax paper. Heat sealing works on cellulose film but not on waxed sheets. I fix confusion by sending a labeled swatch book in every quote kit. This small tool saves hours on artwork and on QC.

| Property | Butter Paper (Waxed) | Baking Parchment7 | Greaseproof | Glassine |

|---|---|---|---|---|

| Coating | Wax | Silicone | None | None |

| Oven use | No | Yes | Limited | No |

| Grease barrier | High | High | Medium | High |

| Printability | Fair | Poor | Good | Good |

| Look | Opaque | Opaque | Semi-opaque | Translucent |

Conclusion

Glassine is simple pulp, smart finishing, and clear trade-offs. I choose it when I need clean looks, light grease control, and easy recycling. I always test and label clearly.

Understanding 'plastic-free'can help you make informed choices about sustainable packaging options. ↩

Explore this link to understand how a laser printer can enhance your printing quality and efficiency. ↩

Learn about solvent-based stamp pads and their advantages for achieving high-quality prints. ↩

Explore this link to understand the benefits and applications of greaseproof paper in various packaging solutions. ↩

Discover the eco-friendly benefits of cellulose film and how it can enhance your packaging choices. ↩

Discover the various applications of greaseproof paper, which can help you make informed choices for your packaging and cooking needs. ↩

Explore this link to understand the versatile uses of baking parchment in cooking and baking, enhancing your culinary skills. ↩