I see brands lose money when boxes bend, crack, or look dull. I also see wins when the right board lifts a product on shelf.

Paperboard choice controls print quality, strength, formability, and cost; choose SBS or FBB for premium print and clean creases, kraft-back for strength and earthy look, and WLC/CCNB for value lines; match caliper and coating to product weight, finishing, and humidity.

I keep this simple. I pick the board for the job first, then I design. This order saves time, cost, and headaches later.

What material is used in folding cartons?

Many people assume "cardboard" is one thing. It is not. Each grade acts in its own way and prints in its own way.

Most folding cartons use SBS (solid bleached sulfate), FBB (folding box board), WLC/CCNB (recycled board), or kraft-back/CRB; pick based on print needs, stiffness, food contact rules, and budget.

How I group the main grades

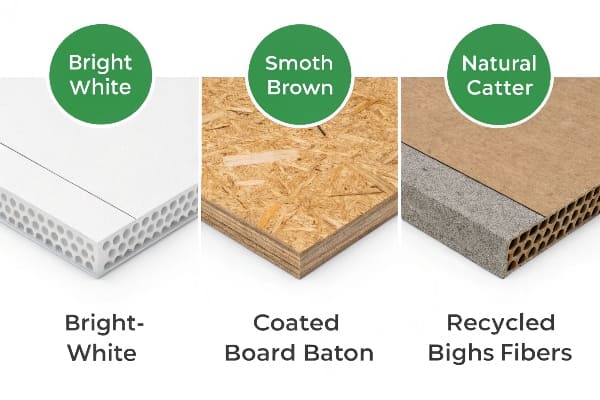

I start with four buckets. SBS1 is virgin fiber, bright, and smooth. It gives top print and clean edges. FBB2 blends mechanical and chemical pulps. It is stiff at lower caliper and often costs less than SBS at the same stiffness. WLC or CCNB uses recycled fiber. It saves cost and supports eco goals, but it can vary in shade and surface. Kraft-back or CRB gives a natural brown back and higher tear. It looks rugged and fits outdoor brands.

What matters most on the shop floor

I look at caliper, basis weight, and moisture. A 16–24 pt SBS works for most beauty or pharma boxes. FBB at 300–400 gsm hits many food and cereal lines. I watch bending stiffness so panels do not bow. I check cracking on folds, especially after foil or heavy ink. I test die-cut waste removal. I check glue hold at mission points. Small fixes here save thousands in packing lines.

Quick comparison table

| Grade | Fiber Source | Surface | Typical Uses | Key Pros | Key Cons |

|---|---|---|---|---|---|

| SBS | 100% virgin bleached | Very smooth, high brightness | Beauty, pharma, premium food | Best print, clean creases | Higher cost |

| FBB | Multi-ply, often virgin top | Smooth, good stiffness/weight | Food, cereal, general retail | Stiff at low caliper | Can micro-crack if grain wrong |

| WLC/CCNB3 | Recycled multi-ply | Varies, often grey back | Value lines, inner cartons | Lowest cost, circular | Shade variation, lower purity |

| Kraft-back/CRB4 | Recycled/brown back | Natural brown reverse | Outdoor, rustic brands | Strong tear, earthy look | Lower brightness, print limits |

I learned this the hard way. I once printed a bold black on a mid-grade CCNB for a rush job. The black looked soft. We switched to SBS and the brand smiled. The reprint cost money, but the shelf impact paid back in orders.

What is the purpose of paperboard packaging?

A box is not only a box. It is a silent sales rep. It holds, protects, and explains. It travels far and must still look new.

Paperboard packaging protects the product, conveys the brand, meets retail handling needs, and optimizes cost; it balances strength, print appeal, machinability, and sustainability across the full supply chain.

Four jobs every carton must do

First, protect. The board must carry the product weight and resist crush and scuff. Second, sell. The carton must print sharp and match brand color. Third, run. It must fold, glue, and erect fast on lines. Fourth, comply. It must pass food or pharma rules if needed and meet retailer standards.

How board choice drives these jobs

SBS wins when you need photo print, foil, and tight reverse text. FBB wins when you need stiffness at lower caliper and good crease memory. WLC wins when cost leads and print is simpler. Kraft-back wins when the story is natural and tough. Coatings also matter. Clay-coated tops print crisp. Polymer or dispersion barriers add grease and moisture holdout for snacks or frozen.

Design-to-board checklist

| Requirement | Board Implication | Test I Run |

|---|---|---|

| Shelf impact | Brightness, smoothness | Delta E color checks |

| Load & stack | Stiffness, caliper | Bending and ECT style checks |

| Fold quality | Grain direction, ply structure | Crease matrix trials |

| Line speed | Glueability, slip | Glue peel, COF |

| Transport | Humidity response | Conditioning cycles |

When my team at PopDisplay built an end-cap for a hunting accessory launch, we picked FBB for the cartons and E-flute trays under them. The cartons stayed sharp in print. The trays carried weight. The display survived a wet weekend road show. The brand ordered a second wave.

What kind of paper is used in carton boxes?

People mix up corrugated boxes and folding cartons. They use different structures and face different tasks.

Folding cartons use paperboard like SBS, FBB, or recycled board from 14–28 pt; shipping cartons use corrugated board like E/B/C-flute; choose paperboard for retail print and corrugated for transport strength.

Paper Rolls

Carton vs corrugated5 at a glance

A folding carton is a single board, cut and creased, then glued side seam. It ships flat and pops open. Corrugated uses linerboards with a fluted medium. It carries heavy loads and stacks high. Retail boxes often use paperboard. Master shippers use corrugated. Many displays mix both. We put paperboard cartons inside corrugated trays, then stack on pallet displays.

Pick by use, not habit

If you need high ink holdout and fine lines, pick SBS or coated FBB. If you need a rustic look, pick kraft-back. If you need to mail, pick corrugated, maybe E-flute for print and B-flute for crush. If you need both, try litho-lam: print on paperboard and mount to corrugated. This gives print pop and stacking power.

Specification table I share with buyers

| Use Case | Recommended Material | Typical Spec | Why It Works |

|---|---|---|---|

| Beauty carton | SBS C1S6 | 18–20 pt | Bright white, sharp foil |

| Cereal carton | FBB | 300–400 gsm | Stiff, food-safe |

| Value inner pack | WLC/CCNB | 18–24 pt | Cost control |

| Mailer shipper | Corrugated B-flute | 32–44 ECT | Transport crush |

| Retail shelf tray | Corrugated E/B-flute | 1–3 ply | Print + strength |

I once tried to save weight on a club-store tray and picked E-flute only. The stack leaned by week two. We switched to B-flute with a litho-lam top. The lean stopped. The cost rose a bit, but returns fell. Buyers loved the clean face and solid feel.

Why folding box board is used for cereal boxes?

This question comes up often in food projects. The short answer is stiffness, safety, and cost.

Cereal boxes use FBB because it is stiff at low caliper, safe for food with proper barriers, cost-efficient at scale, and prints well for bright colors and coupons.

What FBB brings to breakfast aisles

FBB has multi-ply layers. The structure gives high stiffness per gram. This lets brands use thinner boards and still hold shape. Lines run fast because creases form clean. Poly or dispersion barriers handle grease and moisture from liners. Print stays bright. Boxes stack well and face well on shelf. Edges are smooth, which helps when packs rub in transit.

Practical spec and tests

Most cereal boxes run 300–400 gsm FBB with a clay-coated top. I check grain so main panels bend the right way. I cut a crease matrix and run a fold test to check cracking near scores. I condition samples at high humidity. I check glue with cold and hot set. I add a scuff-resistant varnish when boxes ride in open trays. If there is an inner poly bag, I confirm the set-off does not transfer to the bag.

Checklist and trade-offs

| Factor | FBB Advantage7 | Watch-Out |

|---|---|---|

| Stiffness | Holds panels flat at low gsm | Pick right grain |

| Good ink holdout, bright | Match brightness across mills | |

| Food safety | Available with barriers | Validate migration limits |

| Cost | Efficient at volume | Price can swing with pulp |

| Sustainability | High fiber yield | Recycle streams vary by market |

When we built a seasonal cereal promo for a club chain, we faced tight space and strict shelf tests. We chose 350 gsm FBB with a matte top coat and spot UV on brand marks. The boxes stayed square in chill rooms. The colors matched across three mills. The sell-through beat plan by 18%. The buyer sent a thank-you note to our Shenzhen team.

Conclusion

Choose the board first, then design around it. Match grade, caliper, and coating to the job, not the habit. Your shelf wins will follow.

Explore the advantages of SBS paper, known for its superior print quality and clean edges, ideal for premium packaging. ↩

Learn how FBB offers a balance of cost and performance, making it suitable for various food and retail packaging. ↩

Discover the cost-saving benefits and environmental impact of using recycled WLC/CCNB paper in packaging. ↩

Find out why Kraft-back/CRB is favored for outdoor brands due to its rugged look and strong tear resistance. ↩

Explore the advantages of corrugated packaging, including its strength and versatility for shipping and storage. ↩

Learn about SBS C1S, its properties, and why it's ideal for high-quality packaging solutions. ↩

Explore the benefits of FBB in packaging to understand its impact on product presentation and performance. ↩