I sell beauty products. I face tight budgets, fast launches, and strict retail rules. I need packaging that looks good, protects goods, and ships well. I want simple steps.

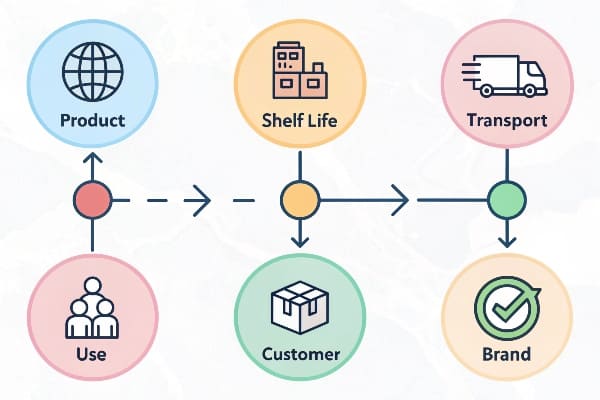

Pick packaging by working backward from the use case: define target shopper and channel, confirm primary pack function and formula fit, map secondary and display needs, then cost, test, and scale with suppliers who can meet deadlines and sustainability goals.

I keep readers who want clear answers and real steps. I share what works for me as a factory owner who ships display packaging for global brands. I focus on choices that save time and reduce risk.

What are the packaging options for cosmetics?

I often feel lost when I see bottles, jars, tubes, sticks, pumps, and boxes. I also need trays and displays for retail. The list grows fast. I break it down by touchpoint.

Cosmetic options include primary packs (bottles, jars, tubes, pumps, droppers, sticks), secondary packs (folding cartons, sleeves), tertiary packs (shipping boxes), and retail displays (PDQ, floor, counter, pallet). Choose by formula type, channel, brand look, budget, and timeline.

Map the landscape in layers

I separate packaging into layers. I start with what touches the formula. I move outward to what shoppers see on shelf, then what logistics needs. This simple map keeps my team aligned when pressure is high.

Layers and common choices

| Layer | Typical Options | Pros | Cons | Best For | Sustainability Notes1 |

|---|---|---|---|---|---|

| Primary2 | Glass bottle, PET bottle, PP airless, tube, jar, stick | Protects formula, dosing | Tooling costs, MOQs | Skincare, color | Refill paths, PCR resins |

| Secondary | Folding carton, sleeve, set box | Print area, brand space | Adds cost | DTC, retail | Recyclable paperboard |

| Tertiary | Corrugated shipper | Protects in transit | Bulky | E-commerce | High recycled content |

| Display | Counter, floor, PDQ, pallet | Visibility, impulse sales | Limited life | Promotions | 100% recyclable designs |

Regional and channel notes

North America is mature. Buyers want stable supply and clear testing. Europe pushes eco rules, so I plan plastic reduction and easy-to-recycle inks and glues. APAC grows fast, so I plan flexible runs and fast digital print. I use PDQ displays in Costco or Walmart to drive impulse buys. I choose flat-pack designs to cut freight. When I plan a global launch, I lock print systems and color targets early to avoid shade drift.

How do I figure out the packaging for my product?

I once tried to match a serum to a pump at the last minute. It leaked during transport. I now start with formula, usage, and test points. I do not skip steps.

Start with formula and use: confirm viscosity, actives, oxygen sensitivity, and compatibility; pick a closure and wiper that dose well; then build the carton, shipper, and display around drop tests, shelf space, margin, and lead time.

A step-by-step path I use

I use a simple path that fits tight timelines. I keep every step short and clear. I document results to avoid repeat mistakes.

Decision path and checkpoints

| Step | What I Do | Why It Matters | Test |

|---|---|---|---|

| 1. Define use | Target shopper, channel, shelf plan | Aligns look and cost | Buyer spec review |

| 2. Confirm formula | Viscosity, pH, actives, solvents | Prevents leach or clog | Compatibility |

| 3. Choose primary | Bottle/jar/tube + closure | Dosing and protection | Pump output, wiper fit |

| 4. Pick secondary | Carton style, board grade | Brand space and stacking | ECT/edge crush |

| 5. Plan tertiary | Shipper count, inserts | Transit safety | ISTA drop |

| 6. Add display | Counter/PDQ/floor | Retail lift | Load and assembly |

| 7. Validate color | Targets, proof loop | No shelf shock | Drawdowns |

| 8. Lock timing | Tooling, print, freight | Hit launch date | Gantt and buffers |

Notes from my factory floor

I run three lines in Shenzhen for cardboard displays3. I handle design, 3D renderings, prototyping, and strength tests. I absorb early changes because repeat orders pay back. For a balm stick, I choose a PP twist-up and a SBS folding carton. For a serum, I choose a glass bottle with a pump and a corrugated PDQ tray for checkout. I keep MOQs low with digital print when buyers test a SKU. I use water-based inks4 and no plastic lamination if a client needs easy recycling. I add a QR code for launch content. I design flat-pack displays that set up in minutes on store floor.

How to decide on packaging?

I feel pressure from budgets, deadlines, and brand goals. I reduce the noise with a short scorecard. I keep it simple and numeric. Then I move.

Use a scorecard across product fit, cost, speed, sustainability, and shelf impact; score each option 1–5; run a quick pilot; lock the highest total that meets buyer specs and margin.

Build a simple scorecard5 that teams accept

I write the criteria in plain words. Everyone can score. We compare options in one meeting. We avoid weeks of back-and-forth.

Sample scorecard (edit to fit your brand)

| Criterion | Weight | Option A: Tube | Option B: Airless Bottle | Option C: Jar + Spatula |

|---|---|---|---|---|

| Formula fit | 25% | 4 | 5 | 3 |

| Shelf impact | 20% | 3 | 4 | 4 |

| Unit cost | 20% | 5 | 3 | 4 |

| Lead time | 15% | 5 | 3 | 4 |

| Sustainability | 10% | 4 | 3 | 3 |

| Display synergy | 10% | 4 | 5 | 3 |

| Weighted total | 100% | 4.2 | 3.9 | 3.6 |

Pilot, test, and scale

I build one master prepress file with color targets. I print a small batch with digital first. I run transport and drop tests in my lab. I assemble a counter display and a floor display. I track setup time and failure points. I ask the buyer to approve die-lines and color drawdowns. I then switch to offset print for scale. I keep the corrugated grade consistent to avoid sag in humid stores. I lock glue types that pass local recycling rules. I keep a record so reorders move fast with minimal changes.

What is the primary packaging of cosmetics?

I often hear people mix up primary and secondary. I keep it clear in my briefs. I teach my team and my clients.

Primary packaging directly touches the formula, like bottles, jars, tubes, pumps, droppers, sticks, and airless systems; it protects the product, enables dosing, and must pass compatibility and safety tests.

Get the primary pack right first

I pick primary based on chemistry and user action. I match viscosity to pump output. I match active sensitivity to barrier needs. I choose wipers that keep applicators clean. I then design the carton and display around the chosen primary.

Primary choices and fit tips

| Type | Best For | Key Fit Tip | Common Risk | Quick Fix |

|---|---|---|---|---|

| Airless bottle6 | Serums, actives | Check oxygen barrier | Spring corrosion | Use PP springless |

| Tube | Creams, gels | Match orifice to viscosity | Oozing | Add membrane seal |

| Glass dropper | Oils | Control drop size | Breakage | Add EVA tray |

| Jar | Balms, masks | Wiper/spatula hygiene | Contamination | Include inner seal |

| Stick | Balms | Smooth twist torque | Sweating | Adjust wax ratio |

Tie to displays and retail

I design PDQ trays7 that hold primary packs snug. I test shelf impact with real lighting. I use bold type and short claims. I keep assembly fast for staff with no tools. In North America, I keep supply steady and repeatable. In Europe, I stress paper-based solutions and clear recycling. In APAC, I plan fast turns and flexible runs. Floor displays keep growing because they win attention fast. I plan stronger corrugated grades for warehouse clubs. I keep flat-pack to cut CO₂ and freight. I use water-based inks and safe glues.

Conclusion

Choose packaging by starting with formula and use, scoring simple options, piloting fast, and scaling with partners who ship on time and meet retail rules.

Discover innovative strategies for sustainable packaging that can help your brand meet eco-friendly standards and consumer expectations. ↩

Explore this link to understand how Primary packaging protects formulas and enhances dosing, crucial for skincare and color products. ↩

Explore how cardboard displays can enhance product visibility and sales in retail environments. ↩

Learn about the advantages of water-based inks for sustainability and recycling in packaging. ↩

Explore this link to understand how scorecards can streamline decision-making and enhance team collaboration. ↩

Explore the advantages of airless bottles for preserving product integrity and enhancing user experience. ↩

Learn how PDQ trays can optimize product visibility and sales in retail environments. ↩