I see more brands ask for protection and low waste. I run a display factory. I test, cut, and ship inserts every week. I know what works and what is greener.

Yes. I offer eco-friendly custom cut inserts. I use recycled-content PE and PET foams, bio-based blends, paper-based pads, and molded fiber. I design inserts to fit tight, ship flat, and use less. I provide test data and certification on request.

I want you to get clear answers fast. Then you can choose the right material, the right thickness, and the right cost. I will show options and trade-offs next.

Is packing foam environmentally friendly?

Many buyers feel lost here. They see green claims everywhere. They also fear damaged goods. I keep the score simple and honest. I compare by source, reuse, and end-of-life.

Some packing foam is eco-friendly. Recycled-content and bio-based foams cut virgin plastic. Reusable and mono-material designs improve recovery. Paper or molded fiber may beat foam for curbside recycling. The best choice depends on product weight, drop risk, and local recycling.

How I judge foam choices

I judge foam by three things. First, material origin. Second, performance per gram. Third, end-of-life. I add one more factor for retail displays. The insert must work with printed cardboard trays and outer boxes. The stack must pass load tests and transit tests. I share one short story. Last year, a sporting goods client needed a PDQ pallet for metal tools. The old insert was virgin EPE. We switched to 65% recycled EPE1 with tighter CAD fits. We saved 18% foam weight and passed ISTA 3A. Damage rate dropped in two waves to under 0.3%. The client kept the look and hit the launch date.

| Criterion | Why it matters | Good options | Watch-outs |

|---|---|---|---|

| Origin | Lower virgin plastic use | Recycled PE/PET, bio-based blends | Supply variance |

| Performance/gram | Less material, same protection | Precise CNC, die-cut ribs | Over-spec density |

| End-of-life | Better recovery | Paper pads, molded fiber | Contamination in mixed streams |

| System fit | Works with displays | Mono-material with corrugate | Mixed materials hard to sort |

| Cost & lead time | On-time launches | Local converting | Exotic resins, long MOQs |

I keep designs mono-material2 when I can. I avoid laminates that mix paper and plastic layers. I mark parts so staff can sort them. I also share simple pack-out lines with big pictures. This reduces waste and rework. It also helps your deadlines.

Is foam paper eco-friendly?

Many people ask for "foam paper." They want a soft look that prints well. They also want curbside recycling. The term covers two very different things. That is where confusion starts.

"Foam paper" can mean foamed plastic sheets with a paper-like finish or paper-based cushion sheets. Paper-based pads are more eco-friendly for recycling. Foamed plastic sheets are light but often not curbside recyclable. Check material codes and local rules.

Two products with one name

I see "foam paper" used for foamed PVC or PE sheets. These are light and smooth. They cut clean and print well. But most curbside programs reject them. I also see paper honeycomb and paper foam boards. These use starch or fiber cores. They pair well with corrugated trays. They usually recycle with cardboard. I use a simple matrix when I guide buyers.

| "Foam paper" type | Base material | Printability | Recyclability | Best use | Notes |

|---|---|---|---|---|---|

| Foamed PVC/PE sheet3 | Plastic | High | Limited | Signage, rigid trays | Light but not curbside in many areas |

| Paper honeycomb4 | Paper | Good | High | Inner blocking, shelves | Strong per gram |

| Molded fiber board | Paper pulp | Moderate | High | Cradles, corner blocks | Good for heavy items |

| Kraft pad with die-cut ribs | Paper | High | High | Box inserts | Works in mono-material packs |

I tell clients to start with the end. If they want curbside recycling, paper-based pads or molded fiber win. If they need thin walls and complex shapes, plastic foam may win on weight. Then I try to cut the part count. I remove tape and labels. I print instructions on the tray. This keeps the system simple. My team in Shenzhen turns these changes into quick samples in three days, so buyers can feel the difference.

What is eco-friendly foam?

I get this question in almost every kickoff call. People want a clear list. They also want real tests. I keep the names plain and the claims small. Then I prove performance.

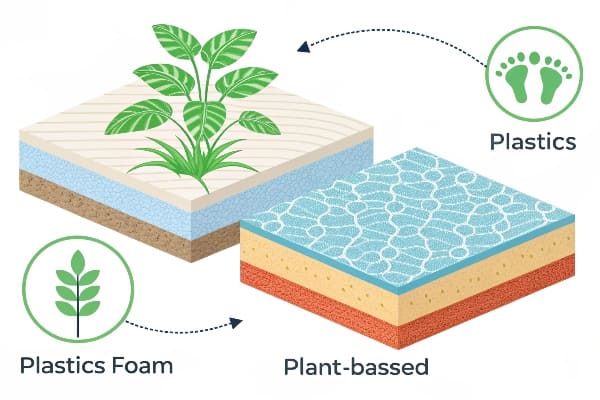

Eco-friendly foam uses recycled or bio-based content, reduces weight, and fits known recycling or reuse paths. Common options include recycled-content PE/PET, EVA blends with bio content, mycelium or starch foams, and paper-based cushions that replace plastic foam.

Options I use and when I use them

I group options by resin and fiber. I match each to product risk and budget. I also check supply. I do not lock you into rare grades that delay launches.

| Category | Example | Strength | Best for | Limits | My tip |

|---|---|---|---|---|---|

| Recycled PE/EPE | 30–70% PCR EPE | Good shock | General retail, light tools | Color variance | Use neutral inks and inner trays |

| Recycled PET foam5 | rPET foam | Good compression | Bottles, cans, cosmetics | Cost vs PE | Great for thermoformed trays |

| Bio-based EVA/PE6 | Sugarcane-based blends | Soft touch | Beauty, premium sets | Certification check | Ask for content test reports |

| Mycelium/Starch foam | Grown or molded | Cradle fit | Gifts, electronics | Moisture, lead time | Plan earlier in the calendar |

| Paper-based pads | Honeycomb, molded fiber | Stack load | Heavy SKUs | Space for rib depth | Design ribs into the art dieline |

I use drop tests, edge crush, and vibration tests. I record pass and fail. I update the CAD to trim more weight. I once cut a fishing gear insert from 24 mm to 18 mm EPE with rib channels. We saved 22% material and passed 1.2 m flat drop on each face. The buyer reordered for the next season. The repeat order covered all design hours. This is how my business model works. I accept small upfront loss and win on steady reorders.

How long do foam inserts last?

People worry about lifespan. They plan launches. They plan reuse in events. They also worry about storage. I measure lifespan by use cycles and by storage time in normal conditions.

Most PE or EVA foam inserts last 2–5 years in normal retail use. Paper-based molded fiber lasts 1–3 years if kept dry. Lifespan extends with correct density, tight fits, clean cuts, and dry storage away from heat and UV.

What controls lifespan and how I design for it

I see lifespan fail for three simple reasons. Wrong density7. Loose fit. Wet storage8. I fix these with better data and small design tweaks.

| Factor | What it does | Good practice | Test I run |

|---|---|---|---|

| Density | Resists crush and fatigue | Match density to product mass | Static load and recovery |

| Fit | Stops rattle and point load | Add ribs, corner locks | Vibration test with logger |

| Cut quality | Prevents tears | CNC or sharp die | Edge inspection plan |

| Climate | Avoids creep and mold | Store at 20–25°C, <60% RH | 72-hour conditioning |

| UV | Slows aging | Opaque shrouds, coatings | Accelerated exposure |

| Reuse cycles | Predicts fatigue | Design handles, remove stress risers | Repack trials with staff |

For trade shows and floor displays, I add finger pulls and quick-lock cuts. Staff can repack fast without tearing the foam. For big-box pallets, I keep inserts modular. If one cell crushes, you swap just that tile. I print a tiny QR on the tray. It links to a one-minute pack video. It cuts training time and damage. One hunting brand asked for 2,000 pallet displays before peak season. We used recycled EPE tiles under a corrugated cradle. We shipped on time. Their return claims fell by half. The inserts were still in service 18 months later in a warehouse reset. This is why small design choices pay off.

Conclusion

Eco-friendly inserts are real. The right pick depends on weight, risk, and recycling. I design for fit first, then weight, then cost. I prove it with tests and simple builds.

Explore the advantages of recycled EPE for sustainable packaging solutions and reducing environmental impact. ↩

Learn how mono-material designs enhance recyclability and simplify sorting, leading to better waste management. ↩

Explore this link to understand the advantages of Foamed PVC/PE sheets, including their printability and applications in signage. ↩

Discover how paper honeycomb contributes to sustainable packaging solutions and its benefits in recycling and strength. ↩

Explore the advantages of Recycled PET foam for sustainable packaging solutions and its impact on the environment. ↩

Learn about the benefits of Bio-based EVA/PE, including its eco-friendliness and applications in premium products. ↩

Understanding the impact of density can help you make informed design choices that enhance product durability. ↩

Exploring the effects of wet storage can guide you in creating better storage solutions to prolong product life. ↩