I see shoppers miss good products when shelves look crowded. Teams lose sales, then rush last-minute. I fix this fast with floor displays that stand out, set up fast, and stay on budget.

Corrugated cardboard floor displays boost sell-through, cut cost, ship flat, assemble fast, carry heavy SKUs, print clean graphics, meet tight deadlines, and recycle easily. I tailor size, flute, coating, and graphics to each planogram and retailer rule, then test strength before mass production.

I will show what matters, why it works, and how I build each display. I will keep it simple. I will share field notes from real launches.

What are the advantages of corrugated cardboard?

Retail teams want strong stands without high freight and long lead times. Buyers want color accuracy and clean edges. I use corrugated because it balances strength, price, speed, and print quality.

Corrugated cardboard gives high strength for low weight, low tooling cost, fast die-cutting, vivid printing, flat-pack shipping, easy assembly, and full recyclability. It supports short promotions and national rollouts with the same material platform and repeatable quality control.

Why I choose it for floors

I get strong columns from flutes, so I hit load targets without metal. I run digital or offset print based on volume, so color stays true. I keep costs low with flat packs1 and simple locks. I can add water-based coatings2 when stores need extra scuff or moisture resistance. This lets me move from brief to sample in days, not weeks. When a client changed SKUs one week before launch, I swapped inserts only. The main body stayed the same. Waste stayed low. Timelines held.

Key factors at a glance

| Factor | What it means | Store impact |

|---|---|---|

| Strength-to-weight3 | Fluted core resists crush with little mass | Safe stacking, less damage |

| Print surface | Smooth liners take sharp color | Brand blocks pop from aisles |

| Flat-pack | Ships compact, assembles fast | Lower freight, faster sets |

| Recyclable4 | Fiber goes back into the loop | Cleaner backroom, greener story |

What are the benefits of corrugation?

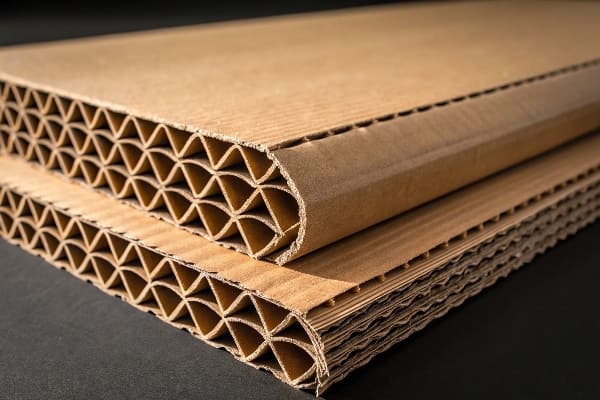

Some displays look big but fail under load. Corrugation prevents this. The fluted core works like tiny arches. It spreads force and protects edges.

Corrugation adds vertical crush strength, bending stiffness, and shock absorption while keeping weight low. Different flute sizes tune stacking, cushioning, and print smoothness, so I match the structure to product weight, footprint, and store traffic.

How flutes solve store problems

Large flutes give cushion for fragile items5. Small flutes give smooth print for detail art. I combine single-wall for light kits and double-wall for heavy gear. I notch tabs so staff snap parts in without tools. I add locking feet6 to spread pressure on glossy floors. Corrugation carries knocks from carts and still stands straight. It also allows smart cut-outs for cables, screens, or security ties. I keep instructions at three steps, with QR video if needed. Teams finish builds before doors open.

Flute guide I use

| Flute | Core benefit | Typical use |

|---|---|---|

| B | Smooth print, good crush7 | Branded wraps, trays |

| C | Balanced strength and cost8 | General floor bodies |

| E | Very smooth, fine detail | Premium graphics panels |

| BC (double) | Heavy load, tall stack | Bulk towers, pallet skirts |

What are the advantages of using cardboard as a modelling material?

I must test ideas fast. Metal or plastic prototypes take time and high cost. Cardboard lets me learn in hours with real sizes and real weight.

Cardboard models are cheap, fast, safe to cut, and easy to change. I validate footprint, sightlines, and load paths before I commit to tooling. I spot risks early, then lock design with confidence.

How I prototype in one day

I print dielines on kraft, cut by plotter, and fold live hinges9. I tape in temporary shelves and add weights to simulate product. I walk the mockup into a retail bay and check reach, ADA clearances, and forklift paths. I test color with a quick digital panel. A U.S. hunting brand once needed a hero tower for a crossbow launch. I built a full-size mock10 overnight, shipped photos by morning, and we approved structure the same day. The final unit hit stores on time.

Model → decision table

| Task | Cardboard benefit11 | Outcome |

|---|---|---|

| Footprint fit | Full-scale check in aisle | No fixture conflicts |

| Load proof | Quick shelf reinforcement | Fewer field failures12 |

| Graphic test | Swappable panels | Cleaner brand blocks |

| Assembly trial | Numbered tabs, short steps | Faster in-store builds |

What are the benefits of cardboard boxes?

Displays travel far. Boxes protect parts and speed set-up. Good box design cuts damage and labor. It also reduces trash on site.

Cardboard boxes protect components, ship flat kits efficiently, and double as PDQ or shelf-ready packaging. Right inserts stop scuffs and bending, while clear labels and kitting lower labor and return rates.

How I pack for zero headaches

I design kits so the first part you need is the first part you see. I number inner bags to match the assembly steps. I print a scannable bill of materials on the box flap. I add corner guards for long panels and strap channels for pallets. For rush programs, I run universal shippers13 that fit multiple store types with one SKU. This reduces pick errors. I test drop and vibration on sample kits. When a retailer banned foam, I switched to die-cut corrugate inserts14. The set-up time stayed the same, and waste dropped.

Box styles that help displays

| Box style | Benefit | Display link |

|---|---|---|

| RSC shipper | Cheapest and strong | Bulk parts and bodies |

| Die-cut mailer15 | Clean unboxing | Counter units and trays |

| SRP/PDQ | Shelf-ready front panel16 | Fast case-to-shelf launch |

| Pallet box | Unitized freight | Store-ready display kits |

What are the qualities of corrugated cardboard?

Not all boards act the same. I choose liners, flutes, and coatings based on weight, print, and store climate. I verify each batch during production.

Quality corrugated has consistent ECT/BCT performance, smooth printable liners, controlled moisture, clean die-cuts, and reliable glue bonds. Optional water-based coatings add scuff and splash resistance while keeping the display recyclable.

What I check before I print

I check crush strength17 and caliper so shelves hold real loads. I check fiber color so brand whites look clean. I check moisture18 to prevent warp. I run make-ready prints and pull drawdowns to lock color. I bend sample tabs 20 times to test crack. I glue sample seams and test peel. I also confirm certifications when buyers ask. Consistent inputs mean consistent displays. This reduces rework and keeps deadlines safe.

Quality checklist summary

| Attribute | What it means | Why it matters |

|---|---|---|

| ECT/BCT | Edge and box strength19 | Safe stacking in transit |

| Caliper | Board thickness20 | Fit, rigidity, insert bite |

| Liner smoothness | Print fidelity | Crisp logos and type |

| Moisture control | Flatness, bond quality | No warp on site |

| Glue and score | Clean folds, strong joints | Fast assembly, fewer breaks |

Why is a corrugated card such a useful product?

Stores change fast. Promotions shift. Corrugated keeps up. It bends into many forms and still tells a strong brand story.

Corrugated card is useful because it adapts to size, weight, and message with low cost, short lead time, and easy recycling. It supports trials, seasonal spikes, and national programs with one flexible material system.

How it supports real retail life

I plan for change. I design modular headers and trays21 so teams swap SKUs without a reprint. I include QR on headers22 that link to setup videos or bonus content. I keep spare inserts on the same pallet, so stores react fast to sales data. When weather delayed trucks, my flat-pack stock let us air-ship part of a program and still set on time. The displays recycled at end of promo, which kept backrooms clear and kept buyers happy. This is why I use corrugated for most floor programs.

Value snapshot

| Use case | Problem solved | KPI effect |

|---|---|---|

| Seasonal promo23 | Short window, low budget | Faster launch, less waste |

| New product trial24 | Unknown demand | Low risk, quick tweaks |

| Heavy SKUs | Load and safety | Fewer collapses |

| Multi-retailer rollout | Different rules | One core, many trims |

Conclusion

Corrugated floor displays help me move fast, protect budgets, and hit retail goals. They look bold. They carry weight. They recycle cleanly. They keep launches on time and buyers calm.

Discover how flat packs streamline production and shipping, leading to significant cost savings in manufacturing processes. ↩

Explore this link to understand how water-based coatings enhance durability and resistance, making them ideal for flooring solutions. ↩

Understanding the strength-to-weight ratio can help you optimize packaging for safety and efficiency. ↩

Exploring recyclable packaging benefits can enhance your brand's sustainability efforts and appeal to eco-conscious consumers. ↩

Explore how flutes can effectively safeguard fragile items, ensuring they remain intact and undamaged. ↩

Learn about the advantages of locking feet in packaging, enhancing stability and pressure distribution. ↩

Discover how smooth print and good crush enhance packaging quality and branding. ↩

Learn about the importance of balancing strength and cost for effective packaging solutions. ↩

Explore this link to understand the innovative use of live hinges in design and prototyping, enhancing functionality and efficiency. ↩

Discover techniques for creating effective full-size mocks, crucial for visualizing and testing product designs before production. ↩

Exploring this link will provide insights into how cardboard can enhance retail displays and improve customer engagement. ↩

This resource will explain the significance of reducing field failures and its impact on overall retail efficiency. ↩

Explore this link to understand how universal shippers can streamline your packing process and reduce errors. ↩

Learn about die-cut corrugate inserts to discover how they can enhance packaging efficiency and sustainability. ↩

Explore this link to understand how Die-cut mailers enhance unboxing experiences and improve customer satisfaction. ↩

Discover insights on how shelf-ready front panels streamline product launches and attract customers in retail environments. ↩

Understanding crush strength is crucial for ensuring that printed materials can withstand real loads, enhancing product durability. ↩

Exploring moisture's impact on printing can help prevent issues like warping, ensuring high-quality outputs. ↩

Understanding edge and box strength is crucial for ensuring safe stacking during transit, preventing damage. ↩

Exploring board thickness helps in achieving the right fit and rigidity, essential for product protection. ↩

Explore this link to understand how modular designs can enhance retail efficiency and adaptability. ↩

Discover how QR codes can connect customers to valuable content, enhancing their shopping experience. ↩

Explore effective strategies for seasonal promotions to maximize your budget and minimize waste. ↩

Learn how to effectively test new products with low risk and make quick adjustments based on demand. ↩