I see buyers ask simple box questions, then face costly mistakes. I break the noise, fix confusion, and share what works in real projects from my display factory.

A practical guide to cardboard boxes covers box styles, materials, and sizing basics, shows the price and recycling math, and explains how to start a small box business with real steps and simple tools.

I keep this guide short and direct. I add notes from my own display jobs. You can use it today in real quotes and store launches.

What is the difference between RSC and HSC boxes?

Most teams mix these two names and lose time. I show you the quick rule so packing lines run smooth and units arrive safe.

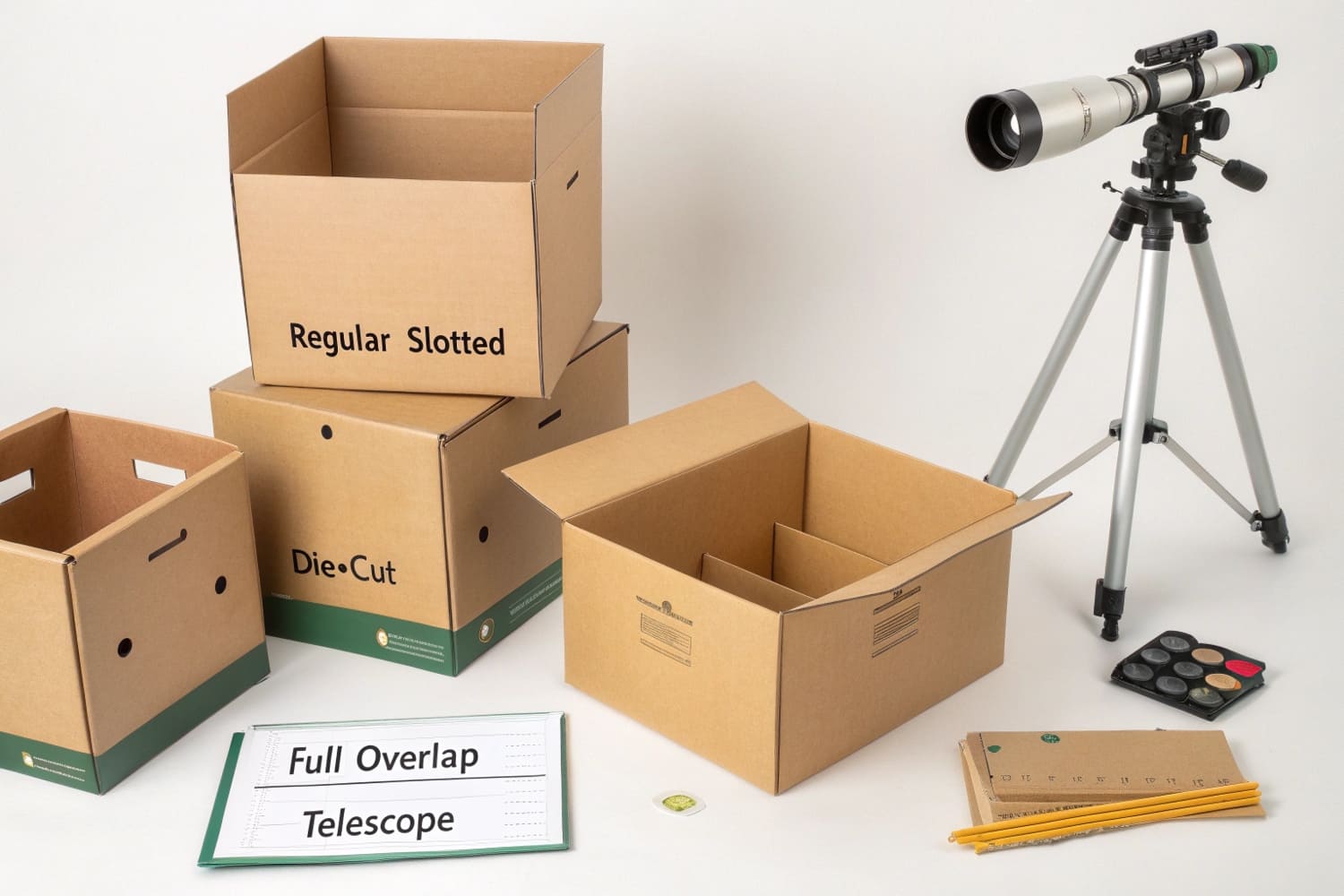

RSC has four flaps on top and bottom that meet at the center; HSC has no top flaps and a separate lid; choose RSC for shipping and HSC for shelf or quick-access cases.

How I compare RSC and HSC in real work

I use both styles every week. When I ship a floor POP display, I pick RSC. It protects edges, holds void fill, and tapes fast. When I build a PDQ (pretty darn quick) tray or a club-store half-pallet, I pick HSC. It opens fast on site and looks clean on shelf. My team in Shenzhen prints the same art for both, but we change fluting and joinery. RSC takes more tape and sometimes needs an inner pad. HSC needs a tight lid and strong corner posts if we stack high.

I learned this the hard way on a hunting-gear launch. The buyer wanted fast in-store setup. We switched the shipper from RSC to HSC with a die-cut lid. Store staff lifted lids, dropped displays, and hit the floor in five minutes. Sell-through jumped that weekend. Since then, I use this test: if speed of opening matters, I choose HSC with a lid; if rough transit is the risk, I choose RSC with edge crush targets set.

Quick spec table

| Feature | RSC (Regular Slotted Carton)1 | HSC (Half Slotted Carton)2 |

|---|---|---|

| Top/Bottom | Four flaps both ends | Bottom flaps only + separate lid |

| Best Use | Shipping, rough transit | Shelf cases, quick access |

| Tape Need | Medium to high | Low (lid or strap) |

| Setup Speed | Medium | High |

| Print Display | Hidden in transit | Often visible in store |

What are the three types of boxes?

People ask for a “type” and get ten names back. I use three simple groups so teams agree on specs and price fast.

The three common types are shipping boxes (corrugated), retail/display boxes (printed paperboard or corrugated), and specialty boxes (rigid or foam-lined) for premium or fragile goods.

What each type means on the line

I put boxes into three buckets because it matches how quotes and risks work. Shipping3 boxes move product from plant to store. They need burst and edge crush numbers. I watch ECT 32–44 for small cases and 48+ for club pallets. Retail or display boxes face shoppers. They need color match, sharp text, and clean edges. I push water-based inks, tight dielines, and easy open scores. Specialty boxes carry high value goods. I add rigid boards, foam, or formed pulp. These take longer and cost more, but returns hurt more.

In my display factory, the second bucket is my core. We build trays, PDQs, and floor displays. I keep print files simple: CMYK plus one spot for brand red or safety orange for hunting tools. I ask for real product weights, not guesses. That stops lean walls that crush. When a client has a tight launch, I standardize parts. One base, one riser, three widths. That cuts tooling cost and speeds reorders.

Type overview table

| Type | Examples | Material | Key Metric | Typical Use |

|---|---|---|---|---|

| Shipping | RSC, HSC, FOL | Corrugated (E/B/C flute) | ECT/Burst | Transit, warehouse |

| Retail/Display4 | PDQ, sleeves, cartons | Paperboard or corrugated | Print fidelity, fit | Shelf, impulse buys |

| Specialty | Rigid gift, foam insert | Chipboard + wraps | Protection, finish | Premium sets, fragile |

How much money do you get for recycling cardboard boxes?

Many buyers guess this number. That leads to bad cost models. I show a simple way to estimate value per ton or per bale.

Recycling prices vary by region and market; OCC (old corrugated containers) often sells from tens to low hundreds of dollars per ton; call local MRFs or haulers for current pickup, bale weight, and gate fees.

How I estimate OCC value for a site

I set a quick model before I promise savings. I ask three things: bale weight5, haul frequency, and current OCC index6 near the plant. Many sites bale 800–1,200 lb each. A small shop may bundle only 200–400 lb. Haulers pay more for clean, dry bales. Wet board drops price fast. I also check if the site mixes paperboard and corrugated. Mixed grades lower value. In my plant, I keep dry zones and clear sort rules. I tag bales and log weights. That record helps me negotiate.

When a client asked if displays could pay for themselves with scrap, I ran a demo. We shipped 10,000 units. We tracked inbound sheets, trim, and outbound cartons. We baled trim and post-use returns. The OCC buyer paid a fair, but modest, price. It did not “pay for the program,” but it offset some waste costs. I still advise clients to treat recycling as a small credit, not as the main lever. The big savings come from right-sizing, lighter flutes, and flat-pack designs.

OCC estimate table

| Input | Typical Range | Why it matters |

|---|---|---|

| Bale weight | 800–1,200 lb (baled) | Heavier bales cut haul cost per lb |

| Moisture | Dry vs wet | Wet bales lose value and risk rejection |

| Grade | OCC vs mixed | Clean OCC earns the best price |

| Local rate | Varies by month | Market demand moves fast |

| Fees | Pickup or gate | Changes net revenue |

How to start a cardboard box business?

New founders try to buy machines first. That locks cash and adds stress. I start with demand, then design, then small runs.

Validate demand with paid samples, use digital print and small die sets first, document repeat SKUs, then scale into converting lines; focus on service, lead time, and QC before capex.

Steps I follow with new lines and clients

I built my display business around repeat orders. I win with design speed, clear proofs, and strong QC. I start with a narrow set: floor displays, PDQs, and shippers. I pitch three standard bases and two header sizes. I show 3D renderings within 48 hours. I send a white sample for fit. I do free edits until the sample passes. Only then do I quote mass runs. For print, I use digital for tests and short runs7. I reserve flexo or litho-lam for scale. This keeps cash safe.

I target buyers who need strict timing. Hunting and outdoor launches hit in seasons. I promise on-time ship8 by building backup slots. I keep color swatches and test loads. I verify ECT with third-party labs when needed. I protect clients from common pain: fake certs, weak glue, crushed corners, color shifts. I fix this with a simple checklist and photo logs. I send these before packing. I track defects by root cause and update specs. When reorder comes, I reuse dies and save time.

Startup roadmap table

| Step | Action | Tool/Metric | Outcome |

|---|---|---|---|

| Validate | Paid pilot, 50–200 units | Lead time, returns | Real demand data |

| Standardize | Fixed bases/headers | Shared dies | Faster quotes |

| Prove quality | Load + drop tests | ECT, glue shear | Fewer claims |

| Scale | Add converting capacity | OEE, scrap rate | Lower unit cost |

| Retain | Reorder program | SLA, color delta | Stable margin |

Conclusion

Pick the right style, set clear specs, price recycling with care, and grow with simple tests, tight QC, and repeat SKUs.

Explore the benefits of RSC for shipping to understand its protective features and efficiency. ↩

Learn how HSC can enhance retail displays and improve customer access with its design. ↩

Discover essential metrics for Shipping box design to ensure product safety and efficiency during transit. ↩

Explore this link to learn effective strategies for creating eye-catching Retail/Display packaging that boosts sales. ↩

Exploring bale weight can reveal significant savings in recycling operations and logistics. ↩

Understanding the OCC index is crucial for optimizing recycling strategies and maximizing profits. ↩

Discover how digital printing can enhance efficiency and quality in short runs, making it a valuable resource for your business. ↩

Explore this link to learn effective strategies for maintaining on-time shipping, crucial for client satisfaction. ↩