I see brands lose buyers at the shelf. I also see margins sink from bad packaging choices. I want to fix this fast and keep things simple.

A folding carton is a printed paperboard box that ships flat, pops up with creases and locks, protects a product, and carries branding at low cost for retail and e-commerce.

I will break the topic into four clear questions. I will give a short answer, a picture idea, and a deeper dive. I will also share a quick story from my factory floor to make it real.

What are folding cartons?

Everyone wants impact at low cost. Many packaging options look good but waste money. Retail buyers judge fast. I care about speed, repeat orders, and fewer returns.

Folding cartons are paperboard boxes made from die-cut sheets with scored folds that ship flat, assemble by hand or machine, and deliver branding, protection, and shelf impact at scale.

The structure, materials, and value chain1

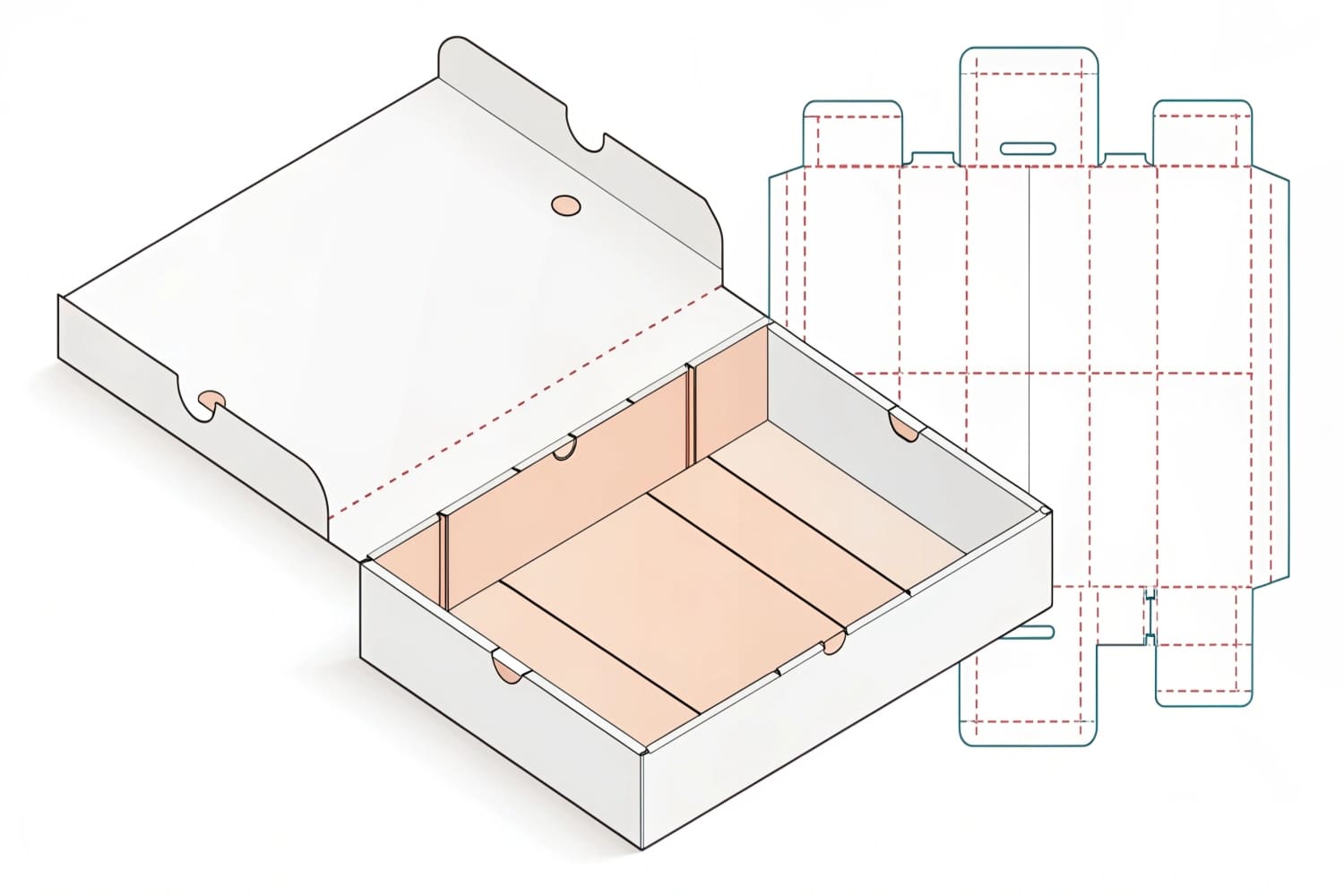

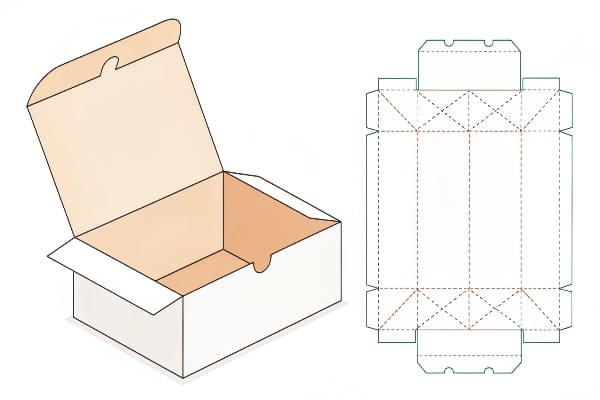

Folding cartons2 work because the format is simple. The supply chain can move flat stacks fast. I start with paperboard sheets. I print graphics with offset or digital presses. I add coatings. I die-cut shapes with steel rules. I score fold lines so assembly is smooth. I ship flat bundles to brands or co-packers. They pop them open, lock the base, and load products. This flow cuts freight, storage, and handling.

There are common styles. Reverse tuck and straight tuck are for light, small goods. Auto-bottom speeds filling. Crash-lock adds strength. Sleeve cartons wrap a tray or inner pack. Windowed cartons show the product and keep tamper seals simple. Inserts keep fragile items in place without plastic. I choose 250–450 gsm SBS or FBB for cosmetics and food. I pick kraft back or recycled board for rugged, natural looks. I add water-based varnish for rub resistance, or soft-touch for a premium feel. I avoid plastic film if the buyer needs full recyclability.

The value is not only cost. Cartons give a large print surface. I can place a brand story, QR code, claim icons, and planogram data. I make barcodes correct and high contrast to avoid chargebacks. I design all panels with grid logic, so the brand blocks on shelf look clean. When a buyer scans a bay, the boxes line up and sell the message. This is why folding cartons still win in stores and in ship-ready kits.

What is a folding box?

Many people say "folding box" when they mean the same thing. I keep the language simple for buyers who just need results on a deadline.

A folding box is the same as a folding carton: a flat-shipped paperboard box with pre-creased folds that assembles quickly to package and present a product.

Where it fits beside corrugated, rigid, and display units

I run a display factory, so I see confusion between a folding box3, a corrugated shipper, and a rigid set-up box4. A folding box uses paperboard and targets the shelf. It favors fine print and tight folds. A corrugated shipper uses fluted board. It is strong for transport but bulkier on shelf. A rigid box uses thick board wrapped with paper. It feels premium but costs more and does not ship flat.

In real projects, I match the pack to the channel. If a brand sells a grooming kit in Target, I suggest a folding box with an auto-bottom and a PET-free window patch alternative like cellulose film or an open window with a secure insert. If the brand needs a club store unit, I pair folding boxes with a corrugated tray or PDQ. The tray handles transport and display. The folding box handles branding and message clarity. For influencer kits or small batch luxury, I might choose a rigid set-up box for unboxing drama, but I warn about freight and storage.

I protect budgets with smart specs. I keep caliper only as high as needed. I add small gussets or lock tabs where tear risk is high. I tighten dielines to reduce paper waste. I group Pantone spots or move to extended gamut if volumes allow. I run transit mocks with drop tests. I control gloss on the main panel to avoid glare under store lights. These choices keep the "folding box" simple, sturdy, and on time.

How to make folding carton?

Tight timelines fail when teams skip steps. I keep a repeatable method. I plan each gate, since speed without checks creates scrap.

I design the dieline, choose paperboard, print, coat, die-cut, score, fold, glue, test, and ship flat; then the packer erects, loads, and closes at the line.

My end-to-end workflow with quality gates5

I start with the product, the shelf, and the buyer brief. I measure size, weight, and any hang-tab or shelf-ready needs. I sketch a structure with safe panel ratios. I build the dieline with clear bleed, glue flaps, and barcode space. I place locking tabs where operators can see and feel them. I add a simple assembly diagram on a tuck flap when teams change often.

I select board grade by load and finish. For cosmetics I use SBS or FBB with 300–350 gsm. For heavier items I step up caliper or add a small inner brace. I print a short run on digital when SKUs change often, or I go offset for larger runs. I use water-based inks and low-VOC coatings to support recycling. I control color with a target strip and a press check. I trap edges and fix tiny type to avoid fill-in.

I die-cut with tight tolerances6. I score with the right rule-to-matrix ratio, so folds are crisp and ink does not crack. I fold and glue on a line with camera checks on critical tabs. I run burst tests and real drop tests on filled samples. I run ship-test stacks to simulate pallets. I document lot numbers and keep retain samples for reorders.

A short story shows why gates matter. A hunting brand pushed me for speed. Their crossbow accessory needed a strong auto-bottom in time for a fall launch. I refused to skip the transit mock. The first mock failed on a diagonal crease. We fixed the score depth and added a micro gusset. The cartons passed. The launch hit the shelf on time. The buyer stayed calm. The reorder came early.

What is a folding box board used for?

People ask about "FBB" or "SBS" and wonder where it fits. I explain use cases so buyers pick the right sheet the first time.

Folding box board (FBB) and solid bleached sulfate (SBS) are paperboards used to print, cut, and fold retail boxes for cosmetics, food, healthcare, and light electronics.

Choosing the right board for strength, print, and sustainability

FBB is multi-ply with a mechanical pulp core and chemical pulp layers. It gives good stiffness at lower weight. It works well for larger cartons that need shape. SBS is pure bleached chemical pulp. It gives a smooth, bright surface for fine images and foil. I choose FBB when I want stiffness value. I choose SBS when I need rich whites and tight deboss or emboss.

Use drives the spec. For skincare I may use 300–350 gsm SBS with soft-touch and spot UV. For chocolate I might use 270–310 gsm FBB with a barrier coating safe for food contact. For a small gadget I might use 350–400 gsm FBB to hold shape with a paper insert. I check regional recycling rules. I prefer water-based coatings. I avoid plastic film lamination unless there is a strict abrasion need. When a brand wants "natural," I switch to kraft back or high-recycled content with a matte varnish and bold type.

Sustainability7 now wins deals. Buyers ask for FSC chain of custody8, recycled fiber rates, and water-based inks. I keep documentation clean and traceable. I print inside panels to reduce extra leaflets. I place QR codes for manuals to save paper. I design for flat packing and high pallet counts to cut carbon in transport. I also plan end-of-life. Pure paperboard with water-based coatings moves through common recycling streams. When we must add a window, I spec easy-to-tear glue lines so staff can separate materials.so staff can separate materials.

Conclusion

Folding cartons give fast setup, clean print, and smart cost. I match style, board, and tests to each channel. I protect timelines with gates. This is how launches stay safe.

Understanding the value chain can enhance your knowledge of packaging efficiency and cost management. ↩

Explore the advantages of folding cartons in packaging, including cost-effectiveness and branding opportunities. ↩

Understanding folding boxes can enhance your packaging strategy, ensuring effective branding and shelf presence. ↩

Exploring rigid set-up boxes can provide insights into premium packaging options that enhance unboxing experiences. ↩

Understanding quality gates can enhance your workflow efficiency and ensure product success. ↩

Learning about tight tolerances in die-cutting can improve your packaging quality and reduce errors. ↩

Exploring this resource will provide insights into sustainable packaging practices that can enhance your brand's eco-friendliness. ↩

Understanding FSC chain of custody is crucial for ensuring responsible sourcing and can help your brand meet sustainability goals. ↩