What Does Pacdora Offer?

I want faster packaging workflows with fewer surprises. I see brands rush to launch, and teams still trade flat PDFs. I need quick 3D, solid dielines, and fewer reworks.

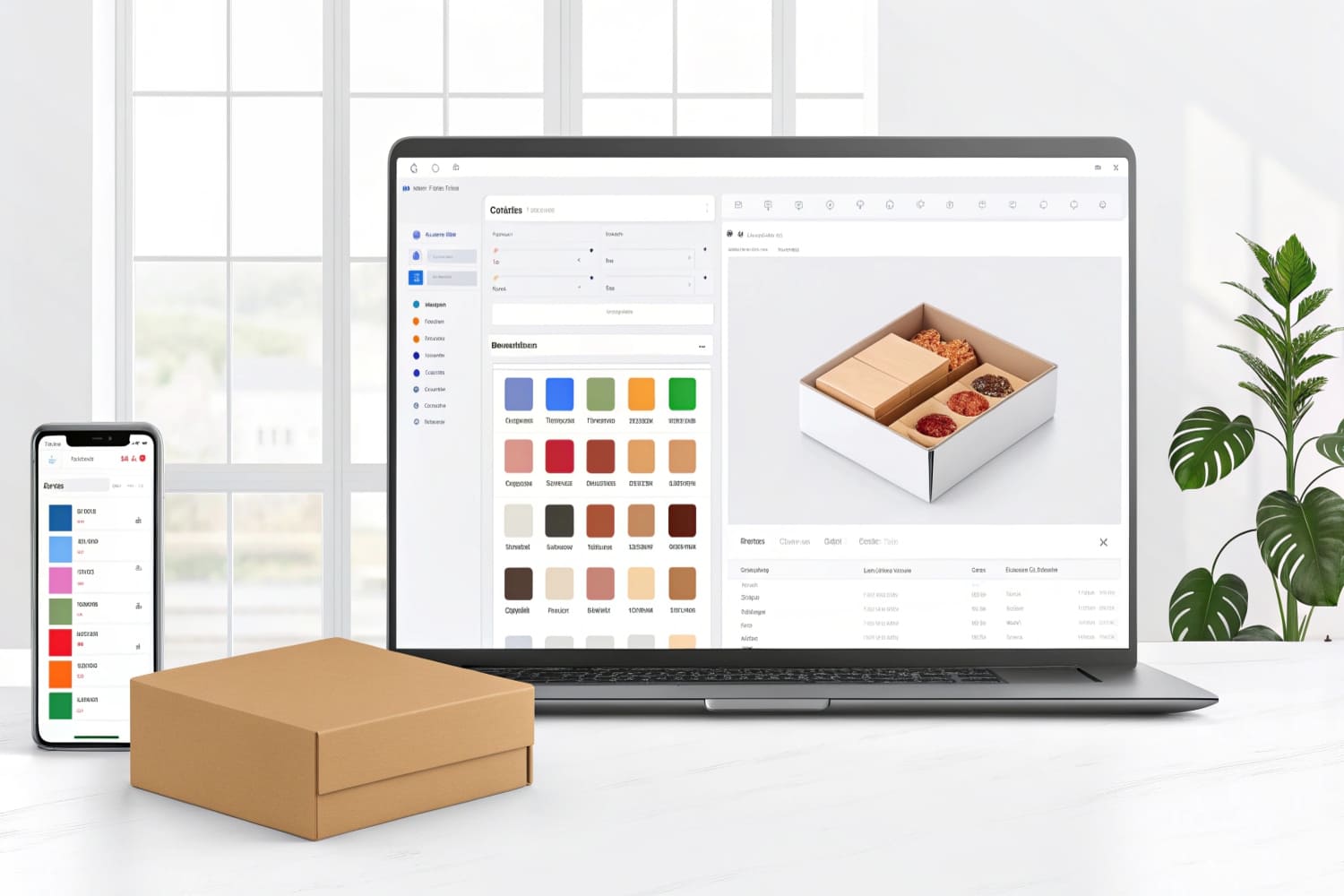

Pacdora offers an online packaging workspace with large dieline libraries, quick 3D mockups, basic parametric resizing, and exports for production teams. It helps me preview ideas fast, reduce rework, and brief factories with clearer files.

I write this for buyers and engineers who want simple answers. I keep the language plain. I also share one short story from my Cardboard Displays work to show how these tools help on real timelines.

What is Pacdora about?

I need tools that make packaging ideas real, not only pretty. I also need clean files that print well. My suppliers ask for clear dielines and tight sizes.

Pacdora is a browser tool for packaging design that combines dieline templates, a 3D previewer, simple editing, and export options for print and CAD. It helps me go from idea to visual proof without heavy desktop software.

How I use it in real POP work

I run B2B display programs1 where speed matters. Floor and countertop displays need strong structure, tight art, and proof that products fit. I start by searching Pacdora’s template gallery2 for a base style near my brief. I adjust length, width, and height to match the SKU footprint. The live 3D view helps me check product spacing and header angles. I swap panels and add simple artwork just to test brand blocking. I then export the dieline and a turntable video for my client. My client sees shape, shelf presence, and copy areas before we cut board. When I build corrugated displays, I still test structure in the factory, like load and transport. Pacdora gives me a head start and reduces the number of wrong samples. This helps when deadlines are strict and launch windows are fixed for retail resets. It also helps me align design, sales, and production on day one.

| Step | What I do | Why it helps |

|---|---|---|

| Pick template | Choose a close box or display style | Cuts discovery time |

| Resize | Enter exact L×W×H | Fits product footprint |

| Quick art | Drop logos and basic colors | Tests brand blocking |

| 3D check | Spin, zoom, screen-capture | Shares vision fast |

| Export | PDF/AI/DXF dielines | Hands off to factory |

Is Pacdora free or paid?

I plan budgets for tools and samples. I do not like surprises. I want to know if the tool is free, paid, or mixed.

Pacdora uses a mixed model with free tools and paid plans. The site shows a pricing page with monthly and annual tiers, while some utilities like the template editor offer free downloads in common formats.

What this means for my display programs

I treat software spend like any other production cost. If a plan lets me export clean dielines and batch mockups, I compare that fee to one extra reprint or a missed slot at retail. Free parts of the tool help my team test early ideas without paperwork. Paid plans make sense when I need higher output, bigger libraries, or clean exports3 without limits. I also weigh this against in-house design time. When I pitch a new floor display to a hunting gear brand, I need fast renders of the tray layout, hooks, and header. If I can deliver three looks in one day, I win trust and move to prototyping sooner. I still treat structure with care. Corrugated needs flute direction, join types, and pallet tests. Software helps me screen ideas, not replace engineering. I put the plan cost against the time saved in the first approved mockup.

| Cost Lens | Measure | Typical Payoff |

|---|---|---|

| Licenses | Monthly or annual | Less rework hours |

| Speed | Time to first mock | Faster client sign-off |

| Output | Number of variants | Better A/B tests |

| Risk | Fewer wrong samples | Lower freight waste |

Can I use Pacdora for free?

I want to try before I commit. I also want basic files to brief my team and vendors. Trials lower risk for my projects.

Yes. I can use parts of Pacdora for free, including entering the template editor and downloading templates in PDF, DXF, or AI. Paid tiers unlock more features, libraries, and usage.

How I start free and scale up

I begin with simple tests. I load a standard tray or carton and set inner sizes for a product family. I export an AI dieline and pass it to my designer. We add brand colors, legal text, and a simple grid. I upload that back into the mockup to check edges and tuck flaps. If the client likes the look, I run a white sample on E-flute and do a quick crush test. If the program needs many variants or more complex shapes, I upgrade the plan for speed and library depth. This saves a week of back-and-forth. In my Cardboard Displays work, this flow helped me rescue a seasonal endcap. We were late. I used the free editor4 to size a tray and back panel. We got sign-off in one day, then moved to sample and mass production. The free step removed friction. The paid plan5 later helped us scale colorways and retailer-specific sizes.

| Phase | Tool Access | Output |

|---|---|---|

| Explore | Free editor | Basic dieline files |

| Prove | Free + light art | Quick 3D checks |

| Scale | Paid plan | Batch variants, larger library |

| Produce | Exports for factory | Faster samples and print |

Is Pacdora legit?

I need tools that are stable and trusted. I care about real users and clear track records. I do not rely on hype.

Yes. Pacdora is a legitimate platform with a public website, active pricing page, live template tools, and many third-party reviews, including Trustpilot entries with high ratings and user comments.

What signals I check before I buy

I check the product site first. I look for working tools, clear exports, and stable performance. I scan the pricing page. I then read third-party reviews6 to spot patterns. On Trustpilot, I look for dates, volume, and the mix of praise and critique. I also search industry forums7. Some users say the mockups are strong for quick visuals. Some say complex corrugated structures still need engineering tweaks, which matches my factory experience. This is normal. I expect any design tool to do visuals well and leave stress tests to production. I check if support replies. I also check if updates keep coming. If these signs look good, I move forward. I start on a small task. I then expand to full programs. This staged approach keeps my risk low and protects my retail timelines. It also keeps my team focused on work that moves the needle.

| Signal | What I look for | Why it matters |

|---|---|---|

| Official site | Working tools and exports | Real product, not vapor |

| Reviews | Recent, balanced feedback | Risk check |

| Forums | Practitioner notes | Practical limits |

| Support | Response and docs | Issue recovery |

| Updates | Ongoing releases | Long-term value |

Conclusion

Pacdora helps me move from idea to clear 3D and clean dielines fast. I still test structure in the factory. This mix saves time, cuts risk, and wins launches.

Explore this link to discover proven strategies that enhance B2B display programs, ensuring impactful presentations and better client engagement. ↩

Check out this resource to learn how to effectively use Pacdora’s template gallery, streamlining your design process and improving efficiency. ↩

Understanding clean exports can enhance your design process, ensuring high-quality outputs and efficient workflows. ↩

Explore this link to discover how a free editor can streamline your design process and enhance productivity. ↩

Learn about the advantages of a paid plan, including access to advanced features that can significantly improve your workflow. ↩

Exploring reliable sources for third-party reviews can help you make informed purchasing decisions based on real user experiences. ↩

Industry forums provide valuable insights and practical advice from experienced users, helping you understand product limitations and strengths. ↩