I meet buyers who want fast sales lifts. Their problem is cluttered shelves and weak packaging. I show them simple display boxes that cut setup time and drive impulse buys. Then I scale.

The main types include countertop PDQ trays, shelf-ready boxes with perforation, floor shippers, dump bins, endcap shippers, pallet displays, sidekicks, clip strips, and windowed folding cartons. Each format solves a placement, capacity, or speed-to-shelf problem across different retail channels.

I use clear categories first. Then I match each product to one box that fits its weight, footprint, and shopper distance. I keep the setup short. I keep the print bold. You can do the same.

What are the different types of display panels?

Shoppers miss messages when panels blend in. That is the problem. Colors fade fast and foam bows. I specify panel types by place and by wear. Then the message holds.

Display panels include header boards, back panels, side fins, aisle violators, and shelf talkers made from corrugated, paperboard, honeycomb board, or foam board. I pick thickness and coating by distance, light, moisture, and expected campaign length.

Materials and formats that actually work

I group panels by the forces they face. Front-of-store needs stiffness and scuff resistance. Checkout needs quick clips. Outdoor foyers need water resistance. I learned this after a rainy launch ruined a set of foam boards. Since then, I moved to coated corrugated or paper honeycomb for long runs. For beauty aisles, I choose paperboard with a satin coating because it prints clean skin tones and keeps edges sharp. I also size aisle violators under 3 inches from the shelf edge to avoid knocks. For sustainability goals1, I avoid PVC. I use water-based inks2 and fiber-only constructions so stores can recycle in one stream. I standardize slot patterns across displays so panels swap in and out during promotions without remaking structures.

| Panel Type | Best Location | Material Option | Strength | Notes |

|---|---|---|---|---|

| Header Board | Top of display | Corrugated E/B-flute | High | Big brand hit, long viewing distance |

| Back Panel | Floor shipper | Honeycomb paperboard | High | Very flat, light, stable |

| Side Fin | Endcap/aisle | Paperboard 18–24pt | Medium | Clean edge, great print |

| Aisle Violator | Shelf edge | E-flute corrugated | Medium | Add radius corners for safety |

| Shelf Talker | Gondola shelf | Paperboard + clip | Low | Use short copy and price callout |

What are the different types of paper boxes?

Teams often overbuild boxes to feel safe. Costs go up. Freight swells. Time slips. I switch to standard paper box styles that pass tests and still save weight.

Paper boxes include folding cartons (straight-tuck, reverse-tuck, auto-lock bottom), mailer boxes, sleeves, gable boxes, rigid set-up boxes, and corrugated shipper cartons (FEFCO 0201). Shelf-ready display boxes add perforation and convert from shipper to tray fast.

Choosing the right box for weight, speed, and shelf rules

I start with the product’s net weight and drop height. Small beauty items suit folding cartons with tuck ends. Heavy jars need auto-lock bottoms3 because they resist splaying. Online bundles ride best in mailer boxes4 since they cushion edges and open clean on camera. For clubs and big box retailers, I spec corrugated 0201 shippers that tear down into trays. I place perforations above the product label height, so the brand line stays intact after opening. I avoid unnecessary lamination. If I need a window, I try fiber windows with die-cut patterns to keep the pack mono-material and recyclable. I run color targets early because uncoated paper reads darker. Short runs get digital print to control MOQs and speed. Long runs get offset to lock color and cost.

| Box Type | Typical Use | Strength | Setup Speed | Note |

|---|---|---|---|---|

| Straight/Reverse Tuck | Light SKUs, cosmetics | Low | Fast | Low cost, crisp print |

| Auto-Lock Bottom | Heavier retail units | Medium | Fast | Strong base, no tape |

| Mailer (E-flute) | DTC/e-commerce | Medium | Medium | Good unboxing |

| Sleeve + Tray | Premium retail | Medium | Medium | Large printable area |

| Rigid Set-up | Gift packs | High | Slow | Premium look, higher cost |

| Corrugated 0201 | Shipping/SRP conversion | High | Fast tear | Add perforation for PDQ |

What are custom display boxes?

Buyers want more than stock. They want speed, strength, and brand voice. That is the challenge. I design custom display boxes that ship flat, pop up fast, and look premium.

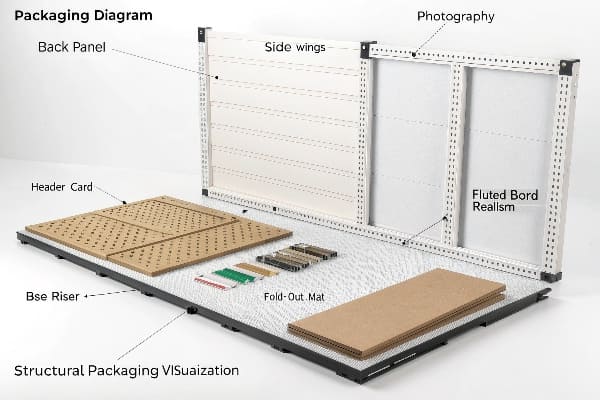

Custom display boxes are branded, engineered boxes or trays that both ship product and convert into ready-to-sell displays. I tailor structure, artwork, inserts, and coatings to weight, store rules, campaign length, and sustainability targets.

How I build customs that install in minutes

I map the retail path first. I ask where the box sits, who opens it, and how many seconds they have. I design tear-strips that avoid barcodes. I add finger cutouts so hands clear in gloves. I choose flute by stack height and pallet pattern. At my factory in Shenzhen, I run three lines that handle design, white-card mockups, and transport tests. I offer free modifications on samples because I want repeat orders later. I do load tests and clamp tests to stop panel bowing and tray sag. I set color bars and aim for tight deltas between sample and mass run. I print with water-based inks5 when possible. I plan inserts from the start so products stand upright and labels face out. I document every spec so reorders run smooth.

| Design Lever | What It Means | Shopper Impact | Production Tip |

|---|---|---|---|

| Tear-to-Tray SRP6 | Ships closed, opens to tray | Faster shelf fill | Keep tears above label line |

| Auto-Lock Base | No tape, strong base | Cleaner look | Use for >500g units |

| Coatings | Matte, gloss, or water barrier | Color pop, durability | Water-based for recyclability |

| Inserts | Die-cut or partition | Stable facing | Match SKU count to casepack |

| Print Method | Digital or offset | Small test lots or big | Use digital for seasonal art |

What are the different types of pop displays?

Stores are noisy. Shoppers rush. Plain boxes fade into the aisle. I use POP formats that pull eyes from four feet away and still pass store limits.

POP displays include floor shippers, dump bins, pallet displays, endcap shippers, sidekicks/power wings, countertop PDQs, shelf trays, and clip strips. I choose by product weight, shopper distance, setup time, and retailer rules on footprint and height.

Picking formats that win space and survive traffic

I look at where traffic flows. For new launches, I use floor shippers near category adjacencies because they carry full case quantities and hit eye level. For small add-ons, I use countertop PDQs near payment points. For warehouse clubs, I like pallet displays since they move from dock to floor with little touch. When I need fast installs, I switch to sidekicks that hang on gondola uprights. They ship pre-filled and clip on in minutes. I keep dump bins for bulky, low-fragile items only, since mixing sizes leads to mess. I add headers with big claims and a clean price area. I keep copy short. I test tear strength and edge crush so units last the whole promo. In my experience, this format mix gives the best balance of impact, cost, and speed.

| POP Type | Footprint | Setup Time | Best For | Notes |

|---|---|---|---|---|

| Floor Shipper7 | 14"–24" square | Medium | Launches, multi-SKU loads | Strong visual block |

| Dump Bin | 20"–30" round/square | Fast | Bulk, low-fragile items | Add rim stiffeners |

| Pallet Display | 40"x48" or 48"x48" | Fast | Clubs, high volume | Ships on pallet |

| Endcap Shipper | End-of-aisle | Medium | Promo tie-ins | Retailer planogram rules |

| Sidekick/Power Wing | 10"–14" wide | Very fast | Pre-filled impulse | Hang on upright |

| Countertop PDQ8 | ≤12" depth | Very fast | Small add-ons | Clear price area |

| Shelf Tray (SRP) | Shelf bay | Fast | Everyday shelf flow | Perforation opens clean |

| Clip Strip | Narrow vertical | Very fast | Lightweight hang packs | Secondary placement |

Conclusion

Choose a box or display by weight, distance, and setup time. Keep the structure simple. Keep the print bold. Test once. Reorder many times.

Learn effective strategies for businesses to meet sustainability goals, enhancing their environmental responsibility. ↩

Explore the advantages of water-based inks for eco-friendly printing solutions and their impact on sustainability. ↩

Learn how auto-lock bottoms provide strength and efficiency for packaging heavy items, ensuring safety during transport. ↩

Explore the advantages of mailer boxes for shipping, including protection and presentation, to enhance your packaging strategy. ↩

Explore the advantages of water-based inks for eco-friendly packaging solutions and their impact on sustainability. ↩

Learn how Tear-to-Tray SRP enhances shelf presentation and improves shopper experience in retail. ↩

Explore this link to understand how Floor Shippers can enhance visibility and sales in retail environments. ↩

Discover insights on how Countertop PDQs can boost impulse purchases and improve customer experience. ↩