I meet shoppers at the shelf. I have one chance to win them. I use simple displays that tell a clear story and move products fast.

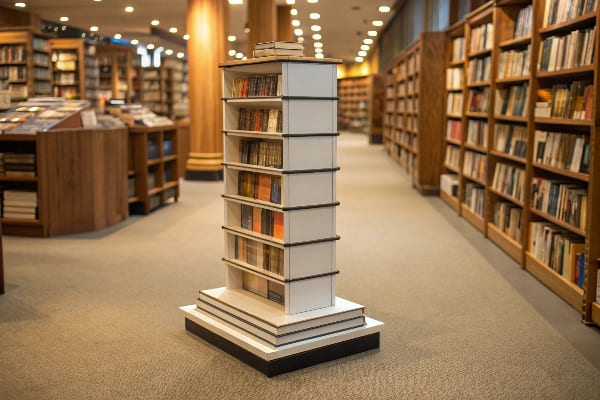

Retail store displays are on-shelf or free-standing fixtures that present products, guide choices, and drive sales in physical stores; they use structure, graphics, and placement to catch attention, explain value, remove friction, and convert impulse into purchase.

I will show what displays are, the five common types, what a good example looks like, and what materials work best. I will add my notes from factory floors and launches.

What are retail displays?

Many shoppers scan fast. They feel choice overload. They skip new items. A clear display cuts noise. It points to a simple next step.

Retail displays are planned structures and graphics that stage products in a store, so shoppers see, learn, try, and buy faster, with less effort and more confidence.

What they are, what they do, how they fit

I use "display" as a broad term. It includes endcaps, floor units, pallet islands, shelf trays, counter units, clip strips, and window sets. Each format does one job well. It earns attention, tells a focused message, and supports fast restock. I plan the path: eye → hand → basket. I keep copy short and big. I use color blocks and clean icons. I place the price near the hand zone. I keep load paths strong. I flat-pack for low freight, then I make assembly steps clear. I follow store rules on size, safety, and fire codes. I test for load, tip, and humidity. I track sell-through weekly. I retire or refresh when the message gets old. In North America I see stable demand. In Asia I see faster growth, new chains, and faster turns. In Europe I see more eco rules and higher bar on recyclability.

| Term | Simple meaning | Main metric |

|---|---|---|

| POP/Point-of-Purchase1 | Display near the buy zone | Conversion rate |

| Planogram fit2 | Match store shelf rules | Compliance score |

| Flat-pack | Ships folded to save space | Freight cost per unit |

What are the 5 types of displays and how are they used?

Shoppers move in set patterns. I match the format to that path. Wrong format equals wasted spend. Right format lifts sales right away.

The five core types are floor displays, countertop displays, pallet displays, shelf/tray displays, and hang tabs/clip strips; each targets a placement, product weight, and buying moment.

Types, best uses, setup tips

I start with floor displays3. These stand alone, carry many units, and make a big visual block. In one study I worked with, floor POP held about 43.7% share of the segment. I see it grow because it hits the line of sight and creates a "shop-in-shop" feel. Countertop units sit near pay points. They push small items and last-minute add-ons. Pallet displays land fast in big-box stores. They ship ready to sell, so labor stays low. Shelf or tray displays sit inside the aisle. They organize facings and boost findability. Hang tabs or clip strips bring small items to eye level near related goods. I also add interactive units when the shopper needs help, like a touch video for a new tool. I choose by product weight, footprint, and time window. Seasonal runs need fast setup and easy teardown. I write one call to action per face. I keep restock paths clear. I print unique IDs on each panel to cut build errors on site. I share a short video with the store team for assembly.

| Type | Where it goes | Best for | Setup time | Notes |

|---|---|---|---|---|

| Floor | Aisle or feature zone | New lines, bundles | Medium | Big impact, needs space |

| Countertop | Checkout, service desk | Impulse SKUs | Low | Small footprint |

| Pallet | Club and mass | Bulk or promo | Very low | Ships ready |

| Shelf/Tray | Aisle shelf | Organization | Low | Uses existing shelf |

| Hang Tab/Clip | Pegs, edges | Small light SKUs | Low | Add-on near related |

Which example describes a good retail display?

Many displays look loud but sell slow. Style without function fails. A good display is clear, strong, and easy to keep full.

A good display has one message, bold price, easy reach, sturdy structure, quick assembly, and clean restock; it matches the shopper mission and the store rules and shows proof of value.

What "good" looks like in the aisle

I test "good" with one question: can a shopper understand and act in three seconds? I keep one headline, one benefit, one price. I cut small text. I show the product outside the box if rules allow. I add a hero image4 that works from six feet. I keep the hand path open. I place variants in a clear order: good, better, best. I add color keys to reduce wrong picks. I place QR or NFC for specs when needed, not to distract. I use corrugated board with right flute for load. I add hidden ribs and locks so it feels solid. I print with water-based inks that match brand colors. I run a pilot in two stores. I track sell-through5 and damages. I change what fails. For example, my client who sells crossbows needed strict dates for a fall launch. We built a pallet island with lockable try-me cradles, large safety icons, and a simple "Choose. Draw. Aim." ladder. It hit the date and beat the target sell-through by week two.

| Aspect | Bad example | Good example | Check |

|---|---|---|---|

| Message | Many claims | One headline + one benefit | 3-second read |

| Price | Hidden or small | Big, near hand zone | Clear value |

| Reach | Blocked facings | Open pick path | Easy grab |

| Build | Wobbly | Locked tabs, strong base | Safe |

| Restock | Confusing | Labeled bays, planogram | Fast |

What are display materials?

I see cost, speed, and sustainability in tension. I choose materials that balance all three. I also plan for local rules and freight.

Common materials include corrugated cardboard, paperboard, foam board, plastics, metals, and wood; brands now favor recyclable corrugated with water-based inks for cost, speed, and sustainability.

Materials, trade-offs, and regional trends

I use corrugated cardboard6 for most runs. It is light, strong for its weight, easy to print, and easy to recycle. Single-wall boards cover many jobs. I move to double-wall for heavy items. Paperboard works for small trays and sleeves. Foam board adds rigidity for headers. Plastics add long life but add waste and cost. Metals and wood fit premium or long-term fixtures. I now add nano-coatings on paper to resist water and UV while keeping recyclability. I choose water-based inks and low-VOC glues. I plan for flat-pack to cut freight. In North America, demand is stable and rules are clear. In Asia, retail grows fast, and speed to shelf wins. In Europe, eco design and recovery rates drive specs. Pulp price swings change costs, so I lock quotes for short windows. Trade actions can raise input costs, so I source local liners when needed. Digital print lets me run small lots with fast changeovers, so I can localize art by region and language without plate costs. I use simple test rigs to check crush strength and transit shocks before I sign off.

| Material | Cost | Durability | Recyclable | Print quality | Best use |

|---|---|---|---|---|---|

| Corrugated | Low | Medium-High | Yes | High | Most POP |

| Paperboard | Low | Low | Yes | High | Trays, sleeves |

| Foam board | Medium | Medium | Partial | Medium | Headers |

| Plastic (PET/ABS) | Medium-High | High | Partial | Medium | Long life |

| Metal | High | Very High | Yes | Low | Premium base |

| Wood | High | High | Yes | Medium | Rustic brand |

Conclusion

Retail displays work when they are simple, strong, and fast to set. The right format, clear message, and fit materials turn foot traffic into sales.

Understanding Point-of-Purchase can enhance your retail strategy and improve conversion rates. ↩

Learning about Planogram fit helps ensure compliance with store rules, optimizing product placement. ↩

Explore this link to understand how floor displays can enhance visibility and sales in retail environments. ↩

Understanding hero images can enhance your product display strategy, making it more appealing to shoppers. ↩

Exploring strategies to boost sell-through can significantly impact your sales performance and inventory management. ↩

Explore the advantages of corrugated cardboard, including its strength, recyclability, and cost-effectiveness for various packaging needs. ↩