Retail aisles are loud and crowded. Shoppers move fast. Teams chase deadlines. I use corrugated display boxes to win space, lift visibility, and keep budgets safe.

Corrugated display boxes are printed retail stands or trays made from corrugated board. They ship flat, assemble fast, hold product, and tell a brand story. They fit floors, counters, shelves, and pallets.

I will keep this guide simple and useful. I will answer the four core questions buyers ask me first. I will add field notes from real launches and tests.

What is a corrugated display?

You need attention at the shelf. You need speed and control. A corrugated display gives both, so stores set up fast and shoppers see the product first.

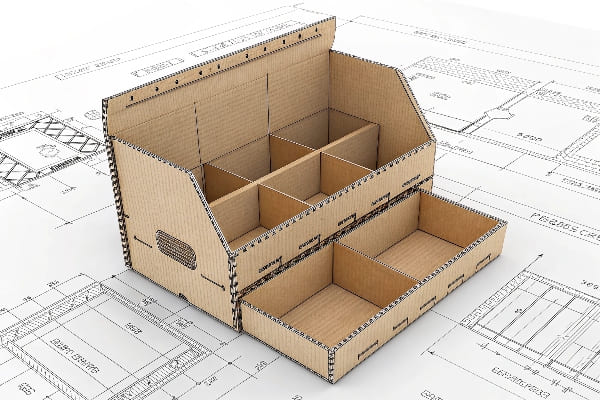

A corrugated display is a printed, branded structure made from corrugated board that holds and presents products in-store or at events. It ships flat and assembles quickly without tools.

What it is and where it fits

A corrugated display1 is a temporary or semi-permanent unit. It can be a floor stand, a countertop tray, a pallet display, a shelf-ready tray, a clip strip, or an interactive unit with screens. I build it from die-cut corrugated parts that lock with tabs or with tape. Stores receive it flat. Teams pop it up in minutes. Brands use it for new items, seasonal pushes, or price events. Data from my category shows floor displays hold a large slice of POP share, near half in some reports, and they keep growing because the visual impact2 is direct. In North America, the market is steady and mature. In Asia Pacific, growth is fast because retail is expanding. Europe pushes eco rules, so recyclable designs win. Digital print helps short runs and fast turns. That helps when deadlines are tight.

Quick structure table

| Type | Best use | Setup time | Notes |

|---|---|---|---|

| Floor stand | Big impact launches | 5–15 min | Great for power aisles |

| Countertop | Impulse items | 2–5 min | Small footprint |

| Pallet display | Club stores | 10–20 min | Ships and sells on pallet |

| Shelf tray | Line extensions | 1–3 min | Shelf-ready packaging |

| Clip strip | Light SKUs | 1–2 min | Use near category leader |

What is a corrugated box?

You ship products every day. You want strength without cost or weight. A corrugated box hits that target and works with supply chains everywhere.

A corrugated box is a container made from layered paper: a fluted medium sandwiched between flat liners. The structure adds strength, cushions shocks, and stays light for transport.

How it is built and why it matters

A corrugated box3 uses three parts at minimum. There is an outer liner, a flute4d medium, and an inner liner. Air in the flutes resists crush and absorbs hits. Single-wall is the most common for display shipping. Double-wall or triple-wall handles heavy kits. I often spec B or C flute for strength, and E flute for fine print on display skins. Tests like ECT and burst guide the grade. Moisture is a risk, so I use water-resistant coatings or nanocoatings when stores are humid. Everything must still recycle. That is why I avoid plastic films unless needed. A box protects the product, but it also protects the display parts. A clean unboxing helps store labor and reduces damage claims. The same board family lets me make both the shipper and the display, so I cut waste and time.

Common flute and use table

| Flute | Thickness (approx.) | Typical use | Print note |

|---|---|---|---|

| E | ~1.6 mm | Display skins, trays | Sharp graphics |

| B | ~3.2 mm | Shippers, trays | Good balance |

| C | ~4.0 mm | Heavier shippers | Strong crush |

| BC (double) | ~7 mm | Heavy kits | High stacking |

What are the benefits of corrugated boxes?

Budgets are tight. Deadlines are closer. I use corrugated boxes because they cut costs, protect goods, and accept clean print for branding.

Corrugated boxes balance strength, weight, and price. They lower freight, protect in transit, print well, recycle easily, and scale from short runs to mass production with fast lead times.

Why teams choose corrugated again and again

Corrugated reduces total landed cost. It is light, so freight drops. It is strong, so damages fall. It prints well, so branding stays clear. It is easy to die-cut and fold, so I can design clever inserts and quick-setup features. It ships flat, so storage costs stay low. It is widely recycled, so it fits retailer and brand goals. In my projects, water-based inks and recyclable adhesives pass store rules and meet eco goals. Asia Pacific demand keeps rising as retail grows. Europe rewards low-plastic builds. North America values stable supply and on-time turns. Display packaging is on a steady path, with mid-single-digit growth expected over the next decade. Corrugated board demand also expands. That scale keeps material options fresh. Digital print lets me run small pilots, then ramp fast. When a timeline is tight, I can prototype, lab test, and move to mass within weeks because the same supply base handles all steps.

Benefits and tips table

| Benefit | Why it matters | Practical tip |

|---|---|---|

| Cost efficiency5 | Less material and freight | Use flat-pack designs |

| Protection | Lower damage rates | Add fit-to-product inserts |

| Speed | Fast print and die-cut | Approve dielines early |

| Branding | High-impact print | Lock brand colors with drawdowns |

| Sustainability6 | Recyclable and PCR options | Pick water-based inks |

| Scalability | From pilot to roll-out | Keep SKUs on common footprints |

What is the difference between box and corrugated?

Teams mix these words. That causes wrong specs and delays. I keep it simple: a box is a form. Corrugated is the material.

“Box” describes the container shape or use. “Corrugated” describes the paper material with a fluted core. Many boxes are corrugated, but some use paperboard, rigid board, or plastic.

Clear terms, faster quotes

I ask one question first: “What form do you want?” That tells me if you need a shipper, a shelf tray, or a full display. I ask the second question next: “What material fits?” That tells me if we should use corrugated7, paperboard8, or a rigid setup. Corrugated boxes use flutes. Paperboard cartons do not. Rigid boxes use chipboard and wraps. If you want a POP unit, you likely want a corrugated display with printed panels and a matching shipper. If you want a small gift box, you may want paperboard. This clarity saves days. Last season, a hunting brand asked for a “box,” but the real need was a club-store pallet display with PDQ trays. We defined the form first, chose BC flute for the tray shippers, used E flute for the display skin, and locked colors with press drawdowns. The setup went live on time in the U.S. and Canada.

Comparison table

| Term | What it means | Common materials | Typical cases |

|---|---|---|---|

| Box | The container form | Corrugated, paperboard, rigid | Shipping, gift, shelf-ready |

| Corrugated | A fluted paper material | Liner + medium | Shippers, POP displays |

| Paperboard | Solid board, no flutes | SBS, FBB | Folding cartons |

| Rigid | Thick board with wrap | Chipboard | Premium gift boxes |

Conclusion

Corrugated display boxes help me win retail space fast. They balance cost, speed, strength, and print. Clear terms and smart specs lead to fewer problems and better sell-through.

Explore this link to understand the versatility and impact of corrugated displays in retail settings. ↩

Discover why visual impact is crucial for retail success and how it influences consumer behavior. ↩

Explore the advantages of corrugated boxes, including their strength, lightweight nature, and eco-friendliness, which are crucial for effective shipping. ↩

Learn about the various flute types in corrugated boxes, their thickness, and applications to choose the right one for your packaging needs. ↩

Understanding cost efficiency can help you optimize packaging strategies and reduce expenses. ↩

Exploring sustainability in packaging can guide you towards eco-friendly practices and materials. ↩

Explore the advantages of corrugated materials, including durability and cost-effectiveness, for your packaging needs. ↩

Learn about various paperboard types and their applications to make informed choices for your packaging solutions. ↩