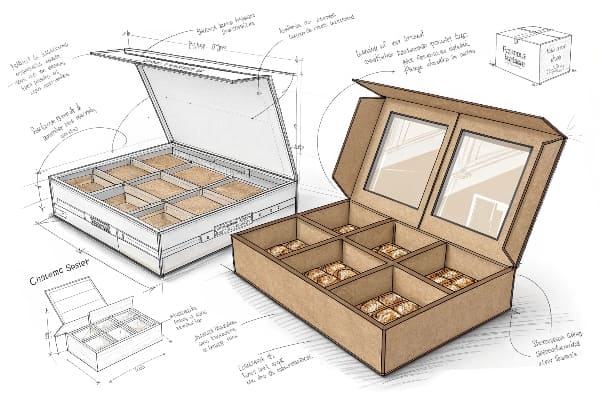

I design and make boxes for stores. I also sell to brands that want fast sell-through. I see a simple truth. A shipping box protects a product. A display box sells it.

Display boxes add branding, structure, and shopper cues that turn packaging into a sales tool, while regular boxes focus on transport and protection; displays optimize visibility, impulse buys, and storytelling right at the point of purchase.

I use display boxes when the shelf must do the marketing. I use regular cartons when the truck and the warehouse need protection. When I mix both in one design, I cut cost and lift sales. Keep reading and I will show my checklists and tables.

What are the benefits of custom display boxes?

I choose custom displays when I need control. I control size, message, and setup time. I also control how the shopper’s eye moves.

Custom display boxes boost visibility, fit the product, and cut setup time; they also support sustainability goals and short runs, so brands move faster, reduce waste, and capture more impulse purchases at lower total cost.

How custom displays create value

My factory in Shenzhen ships into the U.S., Canada, the U.K., and Australia. I see steady demand in North America and fast growth in Asia-Pacific. I design displays that work for short promotions and big launches. Floor displays deliver strong impact. Counter units drive add-on sales. Pallet displays speed setup in club stores. I use digital print for small runs and seasonal art. I use flat-pack structures to lower freight. I use recycled board and water-based inks to meet buyer policies in Europe and big U.S. retailers. My team offers free design tweaks because repeat orders pay back the upfront work. I pressure-test every unit because heavy goods, like hunting tools, need strong board. For Barnett-type projects, I run load and transit tests, lock in color targets, and add assembly marks, so store teams finish in minutes, not hours. Faster setup means more selling days.

| Benefit | Why it matters | Field metric I track |

|---|---|---|

| Shelf impact | Stops shoppers | +15–40% lift on promo weeks (range I see) |

| Fit-to-product | Less damage | <1% returns for crush/lean |

| Fast setup | More selling days | <5 minutes per unit build |

| Cost control | Spend where it sells | Flat-pack cubic reduction 30–50% |

| Sustainability | Retail compliance | 100% recyclable board, water-based inks |

| Short runs | Seasonal agility | Digital print MOQs from 50–100 units |

What are the different types of paper boxes?

I sort paper boxes by structure first. Then I sort by where they live in the store or the supply chain.

Paper boxes include paperboard folding cartons, corrugated mailers, rigid setup boxes, sleeve boxes, and display-ready trays; each type balances print quality, strength, and cost for shipping, shelf, or point-of-purchase needs.

Structures I use most, and when

Paperboard folding cartons give clean edges and sharp print. I pick them for light items and premium looks. Corrugated single-wall (E, B, or C flute) adds strength for larger items. I use mailer-style corrugated for e-commerce and returns. Rigid setup boxes feel premium, so I reserve them for high price SKUs or gift sets. Sleeve boxes slide over trays and let me change art fast. Display-ready trays (PDQ) move from shipper to shelf in one motion, which is perfect for club stores and promo islands. I add hang tabs or clip strips for tiny SKUs near checkout. I keep finishes simple and recyclable. Water-based coatings and strong dielines hold up in real stores. When moisture is a risk, I add a recyclable nano-coating for scuff and splash resistance.

| Type | Best for | Notes |

|---|---|---|

| Folding carton (paperboard)1 | Light goods, premium print | Tight tolerances, low ECT |

| Corrugated mailer2 | E-com, returns | Self-locking, better edge crush |

| Rigid setup | Gifts, luxury | High unit cost, strong presence |

| Sleeve + tray | Fast art changes | Reuse inner tray, swap sleeve |

| PDQ / shelf-ready tray | Grocery, club stores | Tear-away front, quick shelf |

| Hang tab / clip strip | Impulse items | Minimal space, high ROI |

Are there different types of boxes?

I answer yes, and I go deeper than shape. I look at walls, flutes, closures, inks, and coatings.

Yes; boxes vary by board grade, wall count, flute profile, closure style, print method, and coatings, which together set strength, print quality, cost, and recyclability for each retail or shipping job.

What I choose, piece by piece

Wall count comes first. Single-wall is common and cost-effective. I use it for most displays. Double-wall3 handles heavy goods like crossbows or tool kits. Flute choice balances print and crush. E-flute prints sharp for brand blocks. B-flute adds stiffness. C-flute cushions drops. Closures shape labor time. Auto-lock bottoms save minutes on the floor. Tuck tops look clean for counter units. Print methods set speed. Digital wins on short runs and personalization4. Flexo runs fast and low cost. Offset hits premium color. Coatings must pass retailer checks. I use water-based varnish for most units. I add recyclable nano-coats when humidity is high. I lock colors with a simple target sheet, so mass production matches the signed sample. I document board specs, so the sample material equals the production material. This avoids the common failure where a display looks fine on day one but sags in week three.

| Category | Options | When I pick it |

|---|---|---|

| Wall | Single, Double | Double for heavy or tall stacks |

| Flute | E, B, C | E for print, C for cushion |

| Closure | Auto-lock, RSC, Tuck | Auto-lock for speed builds |

| Digital, Flexo, Offset | Digital for 50–500, Offset for premium | |

| Coating | Water-based, Nano | Nano for damp or high-traffic |

| Ink | Water-based | Safer, retailer-friendly |

What are boxes used for in packaging?

I use boxes for more than protection. I use them to guide a shopper and to help a team move fast.

Boxes protect products, present brands, promote offers, speed shelf setup, meet retailer rules, and support sustainability goals, so a single design can cut damage, lift sales, and reduce total landed cost.

Functions that drive my specs

Protection sets the baseline. I size the board and the flutes to pass edge-crush and transit tests. Presentation then drives print and windows. I design brand blocks that stand out from three meters. Promotion asks for clear claim areas and QR codes. Logistics needs flat-pack to shrink freight and faster builds in store. Compliance requires recyclable materials5 and clean labeling. Sustainability is not a side note. Recycled fibers and water-based inks6 are my default. In club and mass retail, pallet displays help teams set full islands in minutes. In hunting and outdoor aisles, heavy gear needs reinforced shelves and hidden bolts. For a crossbow launch, I used double-wall uprights and steel-safe load paths. The unit passed load tests and held color through peak season. The buyer kept the design and reordered with minor art changes, which is my ideal profit cycle.

| Use | Key design choice | Simple metric |

|---|---|---|

| Protect | Board grade, flute mix | Pass ECT/BCT and drop |

| Present | High-read brand panels | 3-meter legibility |

| Promote | Offer zone, QR | Scan-to-buy hits |

| Setup fast | Auto-locks, numbered tabs | <5-minute build |

| Comply | Recyclable inks/coats | Retailer approval |

| Sustain | Recycled content | % PCR and take-back |

Conclusion

Display boxes sell, while regular boxes ship. I design for both. I choose structures, prints, and coatings that match weight, store rules, and speed, so brands win shelf space.

Explore the advantages of folding cartons, including their premium look and suitability for light goods. ↩

Learn how corrugated mailers enhance e-commerce experiences with their self-locking features and edge crush resistance. ↩

Explore the advantages of double-wall packaging for heavy goods, ensuring durability and protection. ↩

Learn how digital printing enhances efficiency and customization for small batch production. ↩

Exploring this link will provide insights into the environmental and economic advantages of recyclable materials in packaging. ↩

This resource will explain the benefits of water-based inks, highlighting their eco-friendliness and safety in printing. ↩