I meet buyers who want attention without waste. They want speed. They want control. They want displays that fit product and brand. I turn that need into simple steps.

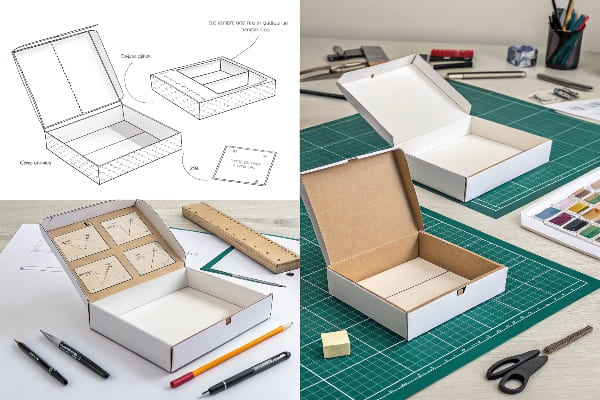

Customizing display boxes starts with goals, then product size and weight, then structure, then artwork, then proofs, then tests, then production, then shipping. I use recyclable board, digital print, clear dielines, and flat-pack designs to cut cost and risk.

I will show what “custom” means in plain terms. I will answer common questions. I will give checklists. I will add one short story from a launch project that nearly failed, and how tight process saved it.

What are custom display boxes?

Many people think a box is just a box. It is not. A display box must sell, protect, and guide the shopper. It must move fast through a store. It must look right under harsh light.

Custom display boxes are branded paperboard or corrugated structures designed to hold and present products in retail, sized to the SKU, printed to brand colors, engineered for strength, shipped flat, and assembled fast by store staff or promoters.

Why a definition matters

I work with food, beauty, and outdoor brands. Each has limits. Food needs hygiene and load tests. Beauty needs color fidelity and clean edges. Outdoor gear needs rugged trays. Custom means I tune each part.

Core elements

| Element | What I decide | Why it matters |

|---|---|---|

| Structure | Floor, counter, shelf, pallet, PDQ | Fits space and shopper flow |

| Board | Single-wall corrugated, paperboard, flute | Balance strength and weight |

| Digital or offset, water-based inks | Color match, MOQ, lead time | |

| Finish | Matte, gloss, nano-coat | Scuff, water, UV resistance |

| Assembly | Auto-lock, tabs, no tools | Fast setup, fewer errors |

| Logistics | Flat-pack, pallet pattern | Lower freight and damage |

Where custom shines

I choose floor units for new launches because they own space. I choose countertop units for impulse. I choose tray displays for tight shelves. I add QR or NFC when the brand wants data. I add AR markers for trials. I keep dielines simple so stores do not struggle. I use recycled board when specs allow1. I test with three drops and a load cycle. I send a short video guide for setup. This plan keeps returns low and sales high.

Can cardboard boxes be customized?

Many buyers ask if cardboard is too weak or too plain. I hear this a lot. I explain that modern board is strong and clean. It also prints well at low volumes.

Yes, cardboard boxes can be customized in structure, size, flute, coating, print method, and branding. I tailor load capacity, moisture resistance, color accuracy, and assembly steps to the product, store rules, budget, and deadline.

Custom options I use

| Option | Choices | I use it when |

|---|---|---|

| Flute | E, B, BE double wall | Heavy items or tall towers |

| Coating | Water-based varnish, nano, anti-scuff | High-traffic or humid areas |

| Digital short-run, offset high-run | Tight deadline vs low unit cost | |

| Inserts | Die-cut, foam-free locks | Secure odd shapes without plastic |

| Color | Brand PMS, extended gamut | Beauty and premium electronics |

| Hardware | Clip strips, hang tabs | Peg walls and narrow aisles |

How I balance trade-offs

I keep sentences simple in my briefs. I ask for product weight and stack height. I ask for store type and aisle width. I choose BE flute for heavy crossbow kits or large bottles. I choose E flute for small cosmetics. I use digital print for pilots and seasonal sets because the setup is fast and the waste is low. I use offset when forecasts are stable and the run is big. I prefer water-based inks and adhesives2 to pass sustainability checks. I use nano-coatings3 when stores have mops and UV lights that punish prints. This mix keeps cost fair and performance reliable.

A short story from the floor

I once built a tall arch display for a holiday launch. The team wanted glossy film. I said no because lights would glare and hurt photos. We switched to soft matte with a nano top. The unit looked calm, reduced scuffs, and met the chain’s recycling rule. Sell-through beat target by 18%. Simple changes did the work.

What are custom retail boxes?

Retail teams need more than a container. They need a silent seller. They need a structure that guides the eye and hand. They need speed from pallet to aisle.

Custom retail boxes are shelf-ready or floor-ready packaging that merges protection with merchandising. They open fast, reveal product, carry brand cues, meet store rules, and drive impulse or planned buys with clear hierarchy.

How I design retail-first

| Layer | Focus | My checklist |

|---|---|---|

| From afar | Stop power | Big contrast, short headline |

| Middle | Shop power | Feature, price holder, QR |

| Close | Hold power | Texture, edge quality, color |

| Backroom | Speed | Tear tape, thumb slots, codes |

| End-of-life | Recycling | Mono-material, peel-free |

Structures that work

I use SRP/PDQ trays for club stores like big-box wholesale because staff moves fast and space turns quickly. I design tear-away fronts with clear finger holes so cases open clean. I add price channels so store labels do not cover art. I design pallet displays to roll in with minimal setup. I include locking tabs that snap with one push. I print a small assembly flow on the inside flap. I color-manage with measured profiles so the orange in the logo stays the same on every run. I also plan reorders with the same dieline to reduce change-over time. This saves budget and keeps brand memory strong.

When sustainability leads

I shift to recycled liners4 when print covers most panels. I cut plastic windows. I use fiber-based substitutes where rules allow. I keep coatings water-based. I plan flat-pack counts that fill a pallet with little air. I add a QR code that links to a story about materials and energy. This helps pass retail audits5 and it builds trust with younger shoppers.

How to ask the grocery store for boxes?

Many small brands and makers start with local stores. The ask feels awkward. It does not need to be. I use a simple script that is clear and polite.

I ask the grocery store manager or receiver at off-peak hours, explain my product and display need, request clean corrugated boxes or space for a PDQ, offer a simple plan for setup and removal, and leave my contact and date.

My script and checklist

| Step | Script line | Tip |

|---|---|---|

| Time | “Hi, do you have two minutes now?” | Go mid-morning, not rush hours |

| Purpose | “I supply a small brand. We use clean boxes for trials6.” | Be honest and brief |

| Fit | “We can place a PDQ near category X.” | Mention aisle and season |

| Value | “Setup takes two minutes. We remove on date Y.” | Reduce their risk |

| Ask | “May I pick up broken-down boxes on Tuesdays?” | Be specific |

| Leave | Card + sample photo | Show proof of care |

Extra notes from busy stores

I keep my request to under one minute. I show a photo of a tidy PDQ in a similar store. I promise to follow their safety rules. I confirm who approves third-party displays. Some chains need corporate approval. Some managers have freedom for small units. I track the date in a simple sheet. I bring zip ties, a box cutter, and a small trash bag. I clean the area after setup. I add a small thank-you note with my phone number on the inside flap. This simple respect keeps doors open.

When boxes are for shipping prototypes

I ask for double-wall7 if I can find it. I avoid produce boxes that may be damp. I choose bakery or cereal boxes because they are clean. I re-tape seams and add edge protectors made from scrap. I label the prototype clearly so it is not mistaken as store stock. I keep the chain intact by offering a quick report of what worked and what did not. People remember the care I show, and they call back for the next test.

Conclusion

Custom display boxes work when goals are clear, structures are simple, prints are honest, and timelines are real. I follow this path, and launches stay on track.

Exploring the advantages of recycled board can help you make sustainable choices in your packaging solutions. ↩

Explore this link to understand how water-based inks and adhesives enhance sustainability and product safety. ↩

Discover the advantages of nano-coatings for protecting products and maintaining their aesthetic appeal. ↩

Exploring the advantages of recycled liners can help you make sustainable choices that benefit both the environment and your brand. ↩

Understanding retail audits can enhance your business strategy and improve customer trust, especially with younger shoppers. ↩

Explore this link to understand the importance of using clean boxes for trials in product sampling, ensuring quality and hygiene. ↩

Discover why double-wall boxes are preferred for shipping prototypes, offering superior protection and durability. ↩