I face this question in almost every project. Customers plan a tight budget. They also need clean cuts and fast turns. I share the same goal. I want a strong, repeatable result.

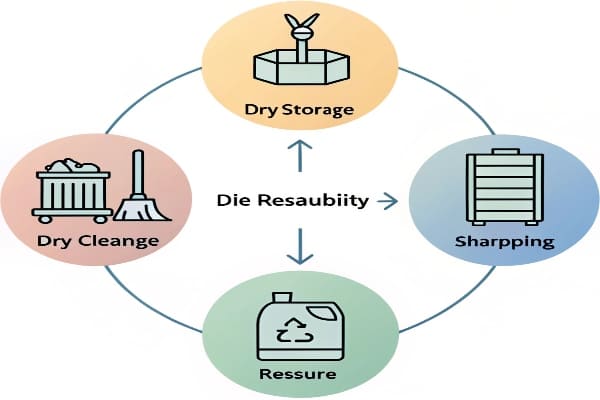

Yes. Most dies are reusable many times if I store, clean, and maintain them. Lifespan depends on die type, material, cutting pressure, and design complexity. Good tooling and regular tune-ups keep edges sharp and costs low over repeat orders.

I will show how die cutting works in packaging. I will explain what a die does. I will cover machines and use cases. I will keep it simple and real. I will add a short story from my floor in Shenzhen.

What is die cut in packaging?

Retail buyers want crisp shapes. Designers want tight tolerances. Operations wants speed. When these needs collide, waste rises. I have seen that happen. Clear terms and simple steps stop this pain.

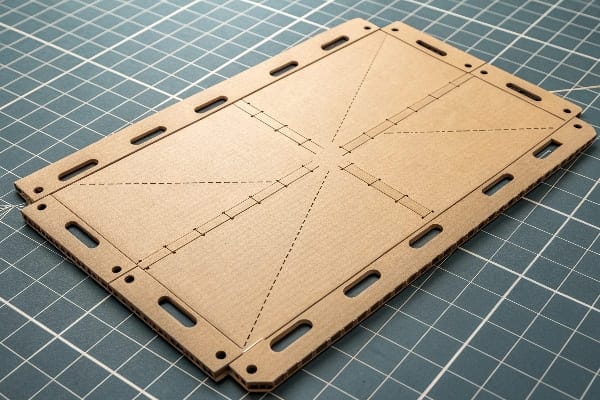

Die cutting in packaging uses a shaped tool to cut, crease, or perforate materials like corrugated board into precise parts so displays, boxes, and inserts assemble fast, look clean, and fit product requirements.

Foundations I use on every project

Die cutting is my daily language on the shop floor. I use it to turn flat sheets into stand-out Cardboard Displays1 for FMCG, beauty, and outdoor brands. I pick a die profile, set the press, and lock the waste plan. I mark crease lines so assembly teams can fold fast in stores like Walmart or Costco. I push for simple shapes when deadlines are tight. I use more complex nicks and windows when the shelf needs drama. My team and I follow three checks: material, blade, and make-ready. The material decides pressure. The blade height sets cut depth. The make-ready evens out pressure across the sheet. This workflow cuts scrap, which lowers cost and carbon. It also helps me hit strict launch dates in the U.S. and Canada. I learned this the hard way on a holiday promo when a fancy window shape slowed packing. We simplified the arc, kept the look, and shipped on time.

| Term | Plain meaning | Why it matters |

|---|---|---|

| Cut | Blade goes through | Clean edges, no fuzz |

| Crease/Score | Compress fiber | Easy folds, strong corners |

| Perforate | Dotted cuts | Tear lines for opening |

| Waste | Offcuts | Lower it to save money |

| Make-ready | Press setup | Even pressure, repeatability |

How does dies work?

Teams often fight unclear specs. Art looks great on screen. The sheet behaves different. If we do not align early, we pay with rework and delays.

A die works by matching a shaped blade and support surface under controlled pressure, so the blade cleanly separates or compresses fibers along the intended path without crushing or tearing nearby areas.

What is inside the tool and why it matters

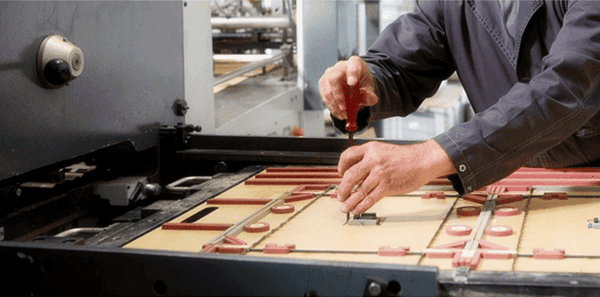

Most display work uses a steel-rule die2. It has a plywood base, laser-cut slots, and steel blades bent into shape. Rubber ejectors push parts out after the cut. For thicker corrugated, I select higher blade heights and softer rubbers to avoid crush. For micro-flute beauty displays, I use finer rules and tighter tolerances. Solid dies and rotary dies exist too. They suit massive runs or continuous web lines. The press delivers force. The cutting plate or anvil supports the sheet. The make-ready materials3 under the sheet even the pressure. If pressure is too low, you get tags. If pressure is too high, you crush flutes and weaken walls. I train operators to check four quick signs: full light test around edges, smooth crease bead, stable fit in assembly, and stack lean. When we pass these checks, we can reuse the same die for repeat orders with only light re-knifing. That is how our profit model works: we accept small upfront losses in design and prototypes, then we ship reliable reorders with the same tooling.

| Component | Simple description | Typical choice for displays |

|---|---|---|

| Blade (rule) | Steel strip edge | 2–3 pt height by board |

| Ejector rubber | Pushes waste out | Harder for cuts, softer near creases |

| Base | Holds blades | Laser-cut birch plywood |

| Make-ready | Underlay to level | Spot sheets and tape |

| Anvil/Plate | Support surface | Flatbed cutting plate |

What is a die cutting machine used for?

Many buyers mix up printers and cutters. I keep the goal clear. Printing adds graphics. Cutting creates shape and fold. Both must align, or colors and edges drift.

A die cutting machine applies controlled force with a die to cut, crease, or perforate sheets or rolls, turning printed board into finished parts for displays, boxes, inserts, and retail packaging.

Machines I run and when I use them

I use three machine families. First is digital cutting tables4. They use knives instead of fixed dies. They shine for prototypes and small lots. They remove tooling time and help me iterate artwork with brand teams fast. Second is flatbed die cutting presses5. They drive a platen into a stationary die. They deliver strong, even pressure for corrugated board. They rule the POP display world for floor stands, PDQs, and trays. Third is rotary die cutting. It runs on high speed with cylindrical dies. It suits long runs and narrow web. I match the machine to run size, deadline, and material. When a U.S. outdoor brand needs 300 test units for a hunting launch, I use digital first, then shift to flatbed for the 3,000-unit rollout. This staged plan protects dates and budget. It also reduces waste because we lock tolerances early. Good scheduling keeps print and cut in register. Good pallets and straps stop transit damage, which is a key buyer pain point.

| Machine type | Best for | Pros | Cons |

|---|---|---|---|

| Digital table | Samples, short runs | No tooling, quick edits | Slower per unit |

| Flatbed press | Corrugated displays | Strong crease, repeatable | Tooling lead time |

| Rotary press | Long, narrow web | Very fast | Costly tooling, limits |

What is the purpose of a die?

Teams sometimes ask why we cannot just “CNC everything.” We could, but we would pay more per unit for scale runs. The right tool gives speed and consistency.

A die’s purpose is to create repeatable shape and fold lines at scale, so every unit assembles the same way, fits product, ships flat, and holds brand quality without constant adjustments.

Why the die pays for itself over time

A well-built die saves real money after the first run. It cuts cycle time. It locks dimensions. It lowers training needs for store assembly teams. It also supports our sustainability goals6 because we can nest parts tightly and reduce scrap. Reuse is the core value. We track dies with IDs, photos, and storage racks. We log hits and edge wear. When blades dull, we re-knife only where needed. When rubber hardens, we swap strips. I set simple rules: clean dies before storage, wrap them, and store vertical. We inspect before each setup. These habits let us reuse dies for many reorders. This is how we serve strict launch calendars for brands in the U.S., Canada, the U.K., and Australia. I remember one crossbow display program where color shifts caused returns. The die was fine. The ink profile was off. We fixed the print ICC and reused the same die for all reprints. The consistent cut saved the schedule and protected cost.

| Benefit | How it shows up | Buyer impact |

|---|---|---|

| Repeatability | Same fit every time | Fewer assembly issues |

| Speed | Shorter setup time | Better on-time delivery |

| Cost | Lower per-unit over runs | Budget control |

| Sustainability | Less scrap, flat ship | Lower footprint |

| Quality | Clean edges, strong creases | Premium shelf look |

Conclusion

Dies are reusable. Good care, smart machine choice, and simple checks turn one tool into many reliable runs.

Learn about the design process of Cardboard Displays to enhance your retail marketing strategies. ↩

Understanding steel-rule dies is crucial for optimizing display production and ensuring quality cuts. ↩

Exploring make-ready materials can enhance your knowledge of pressure management in cutting, leading to better results. ↩

Explore this link to understand how digital cutting tables can enhance your production efficiency and reduce costs. ↩

Discover the benefits of flatbed die cutting presses and how they can optimize your display manufacturing process. ↩

Exploring this link will provide insights into how sustainability goals can enhance efficiency and reduce costs in manufacturing. ↩