Retail aisles look crowded, and your product gets ignored. That pain costs sales. A smart cardboard display box lifts items to eye level and changes the story.

The main types of cardboard display boxes include counter displays, floor-standing units, dump bins, pallet displays, end-cap displays, and brochure holders, each crafted to match product size, weight, and promotional goal.

I will walk you through every option, show real factory insights, and help you pick the box that moves products faster than your rivals.

What are the different types of cardboard cartons?

Crowded warehouses lead to damage, delayed launches, and angry buyers. I felt that sting in my early years.

Common carton types are regular slotted, half-slotted, full overlap, telescope, and five-panel folders, each serving unique packing needs and cutting waste.

Shape, flap, and strength

Choosing a carton means matching structure to shipping stress, branding, and budget. Below I group the most used cartons and explain when each wins.

| Carton Type | Key Feature | Best Use | My Shop Tip |

|---|---|---|---|

| Regular Slotted (RSC)1 | Four equal flaps | General freight | Add inner pads for fragile items |

| Half-Slotted (HSC)2 | Open top | Quick shelf loading | Pair with custom lid for retail-ready feel |

| Full Overlap (FOL) | Flaps overlap fully | Heavy loads | Use water-based ink to keep weight down |

| Telescope | Two bodies slide | Extra crush strength | Print bold graphics on outer shell |

| Five-Panel Folder3 | One long crease | Long products | Reinforce ends with corner posts |

Everyday I juggle these choices for clients across hunting gear, snacks, and toys. Long crossbows from Barnett Outdoors ride safely in five-panel folders. Lightweight promo mugs sit in half-slotted cartons so stores unpack them fast. Over time I learned one rule: start from the product’s weak spot, then pick a carton that shields it first and wows shoppers second. That sequence saves money and claims repeat orders, which is how my business stays profitable even after free prototyping costs.

What are the different grades of cardboard boxes?

A bent display ruins launch day and dents trust. I lost a big order once because the board sagged.

Cardboard grades run from single-wall E-flute up to triple-wall AAA, with higher flute counts giving more cushion and stacking strength for heavier goods.

Flutes, liners, and hidden math

Grade choice is a mix of physics and cost. Below I map flute profiles4 to real retail weight limits and share test data from my plant.

| Grade | Flute Height | Layers | Typical Load | Use in Displays |

|---|---|---|---|---|

| E-Flute | 1.2 mm | Single | <5 kg | Cosmetic trays, brochure holders |

| B-Flute | 2.8 mm | Single | <10 kg | Counter displays for snacks |

| C-Flute | 3.6 mm | Single | <15 kg | Floor stands for cereal |

| BC-Double | 6.6 mm | Double | <25 kg | Dump bins for toys |

| AAA-Triple | 10 mm | Triple | <50 kg | Pallet displays for engines |

I run edge crush tests5 weekly. Results guide which grade goes to which buyer. A double-wall board6 might cost 8 % more than a single-wall, yet saves 20 % in damage claims. For David at Barnett, I use BC flute on crossbow displays. It holds weight yet keeps freight light. I always show clients sample corners so they feel stiffness before they sign off. That tactile proof wins trust faster than any brochure.

What are cardboard displays called?

New buyers search online with random words and miss key suppliers. I watched leads slip because naming was unclear.

Cardboard displays are also called POP displays, POS stands, corrugated exhibits, retail dumps, and shelf-ready packs, terms that shift with region and industry.

Language shapes buying speed

Names vary, but the purpose stays the same: pull the shopper. Here are common labels and where you will hear them.

| Term | Region / Sector | Sub-Types People Mean | Why the Mix Matters |

|---|---|---|---|

| POP (Point of Purchase7) | North America retail | Counter, floor, pallet | Buyers seek impulse boost |

| POS (Point of Sale8) | EU, AU stores | Same as POP | Used in tender specs |

| Corrugated Standee | Toy and cinema promos | Character cut-outs | Boosts theme campaigns |

| Dump Bin | Grocery | Bulk low-value items | Needs strong walls |

| Shelf-Ready Pack9 | Big-box chains | Tray + tear-away lid | Speeds shelf restock |

Knowing the right label speeds quote requests. When a U.K. chain asks for POS trays I translate specs into my mould library in minutes. My team’s fast reply beats slower factories. That solves David’s pain point of poor communication. Clear terms slash back-and-forth emails and lock production windows early. It also improves SEO on my Alibaba listings. I tag both POP and POS so global buyers land on my page first.

What are the names of different types of cardboard?

Designers often mix board names with trademarked brands and confuse purchase orders. I once received the wrong liner because of that.

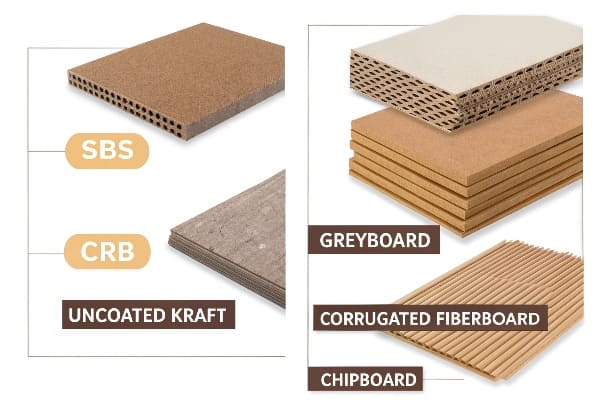

Cardboard types include solid bleached sulfate (SBS), coated recycled board (CRB), uncoated kraft, corrugated fiberboard, chipboard, and greyboard, each defined by fiber source and finish.

Fiber, finish, and printing impact

Material choice drives color pop, ink absorption10, and fold memory. Below is my field guide.

| Cardboard Type | Fiber Source | Surface | Best For | Cost Tier |

|---|---|---|---|---|

| SBS | Virgin, bleached | Bright white | Luxury cosmetics | High |

| CRB | 100 % recycled | Coated white | Eco toys | Medium |

| Kraft (CCNB) | Mixed pulp | Brown | Rustic branding | Low |

| Corrugated Fiberboard | Liner + flutes | Brown or white | Structural displays | Medium |

| Chipboard | Recycled | Grey | Inner stiffeners | Low |

| Greyboard | Mixed waste | Dark grey | Book covers | Low |

In my plant I laminate a white SBS top sheet over kraft liners for premium hunting displays. That mix keeps structure stiff yet shows vivid deer graphics. Recycled CRB works when U.S. buyers demand green claims. I keep FSC and ISO certificates11 ready to squash fears of fake paperwork. Showing real audit photos inside the factory further calms clients. By pairing the right board with honest proof, I convert first-time buyers into repeat partners.

Conclusion

Choose the right carton style, board grade, display term, and material, and your product will stand tall, survive shipping, and outsell the competition.

Explore the benefits of Regular Slotted cartons to understand how they can optimize your shipping process and protect your products. ↩

Discover how Half-Slotted cartons can streamline your retail operations and improve customer experience with quick shelf loading. ↩

Learn how Five-Panel Folders enhance product safety during shipping, ensuring your long products arrive intact and undamaged. ↩

Exploring flute profiles will help you choose the right packaging for your products, optimizing both cost and durability. ↩

Understanding edge crush tests can enhance your knowledge of packaging strength and performance, crucial for product safety. ↩

Learning about double-wall board advantages can lead to better packaging decisions, reducing damage claims and costs. ↩

Understanding Point of Purchase can enhance your retail strategy and improve customer engagement. Explore this resource for valuable insights. ↩

Discover how Point of Sale systems can streamline transactions and boost sales efficiency in your business. ↩

Learn how Shelf-Ready Packs can optimize your inventory management and enhance customer experience in stores. ↩

Understanding ink absorption is crucial for achieving vibrant prints and ensuring quality in your projects. Explore this link to learn more. ↩

FSC and ISO certifications are vital for ensuring sustainability and quality in materials. Discover their importance and benefits here. ↩