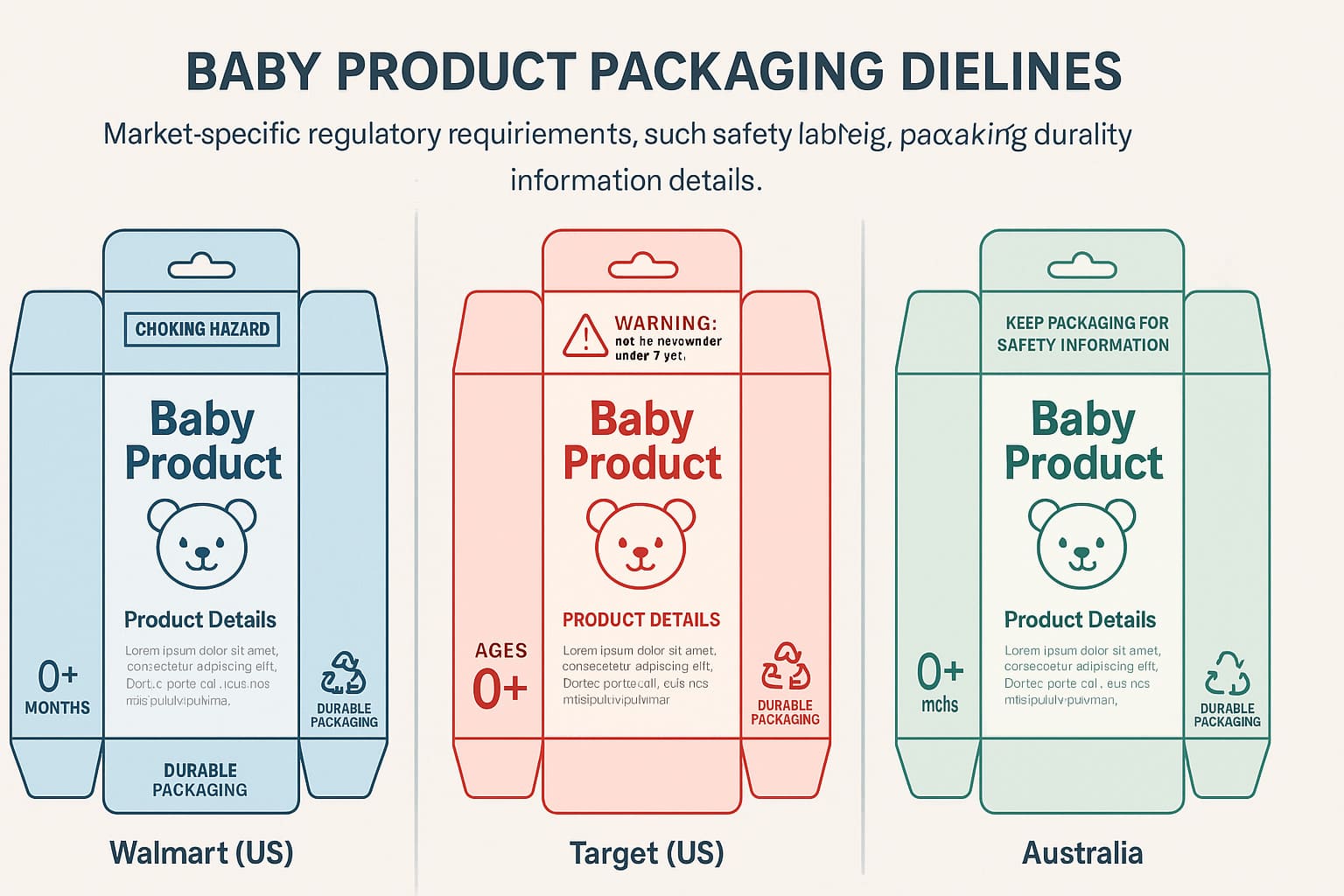

如何为双人市场婴儿产品(澳大利亚 +美国)设计沃尔玛和符合目标的包装载盐?

我注意到,为可以满足美国和澳大利亚市场的婴儿产品设计包装并非易事。成功的关键在于了解沃尔玛和塔吉特等零售巨头制定的法规和准则,以及使它们与澳大利亚零售标准保持一致。但是,如何设计适合两个市场无缝工作的包装呢?让我们探索。

为美国和澳大利亚市场设计包装都要求您了解沃尔玛和目标的合规性法规,同时考虑到澳大利亚零售要求。这些零售商具有必须遵守的严格包装规格,并有效地平衡它们将节省您的时间和金钱。

重要的是要意识到,尽管美国和澳大利亚都是讲英语的市场,但它们的零售环境和包装要求可能会有很大差异。确保您的包装Dieline满足沃尔玛和目标的需求,同时也遵守澳大利亚法规。让我们深入了解如何实现这一目标。

婴儿过道的必需品:如何为沃尔玛,目标和澳大利亚零售商创建通用的二线?

为沃尔玛,目标和澳大利亚零售商创建一个通用的二线线,需要对每个市场的独特合规性需求有深刻的了解。尤其是婴儿产品,对安全性,标签和耐用性提出了严格的要求。那么,我们如何确保我们符合这些标准而不会损害设计?关键是在满足所有监管要求的同时确保二线内的灵活性。

为了为适用于沃尔玛,目标和澳大利亚零售商有效的婴儿产品创建通用二线,您必须确保设计适应性且符合这些市场的安全性,标签和包装规定。了解和对齐每个市场的准则将有助于简化流程。

在设计双人市场产品的二线线时,要考虑几个因素至关重要。例如,美国市场强调遵守消费者产品安全委员会(CPSC) 1指南,该指南管理产品安全和标签。澳大利亚竞争和消费者委员会(ACCC) 2 澳大利亚法规也强调了严格的标签要求3 ,尤其是针对婴儿产品。

双市包装的关键设计注意事项

这是针对这两个市场设计时需要关注的关键要素的细分:

| 考虑 | 美国要求 | 澳大利亚要求 |

|---|---|---|

| 标签4 | CPSC法规,清晰的产品名称,成分和警告 | ACCC标准,双语标签(如果适用,英语和另一种语言) |

| 安全警告 | 警告标签年龄限制,窒息危险 | 类似的警告,但也可能需要有关包装的更多详细信息 |

| 耐用性5 | 包装强度以承受运输和处理 | 耐用性对于确保在运输过程中不会损坏产品至关重要 |

| 使用的材料6 | 必须符合沃尔玛等零售商设定的特定标准 | 环保材料可能是澳大利亚首选的 |

| 条形码和SKU | 沃尔玛和目标需要某种格式和安置 | 澳大利亚零售商可能会遵循不同的条形码系统,因此需要灵活性 |

| 大小和形状 | 取决于零售商的显示单位 | 相似的大小指南,但必须适合当地零售货架单元 |

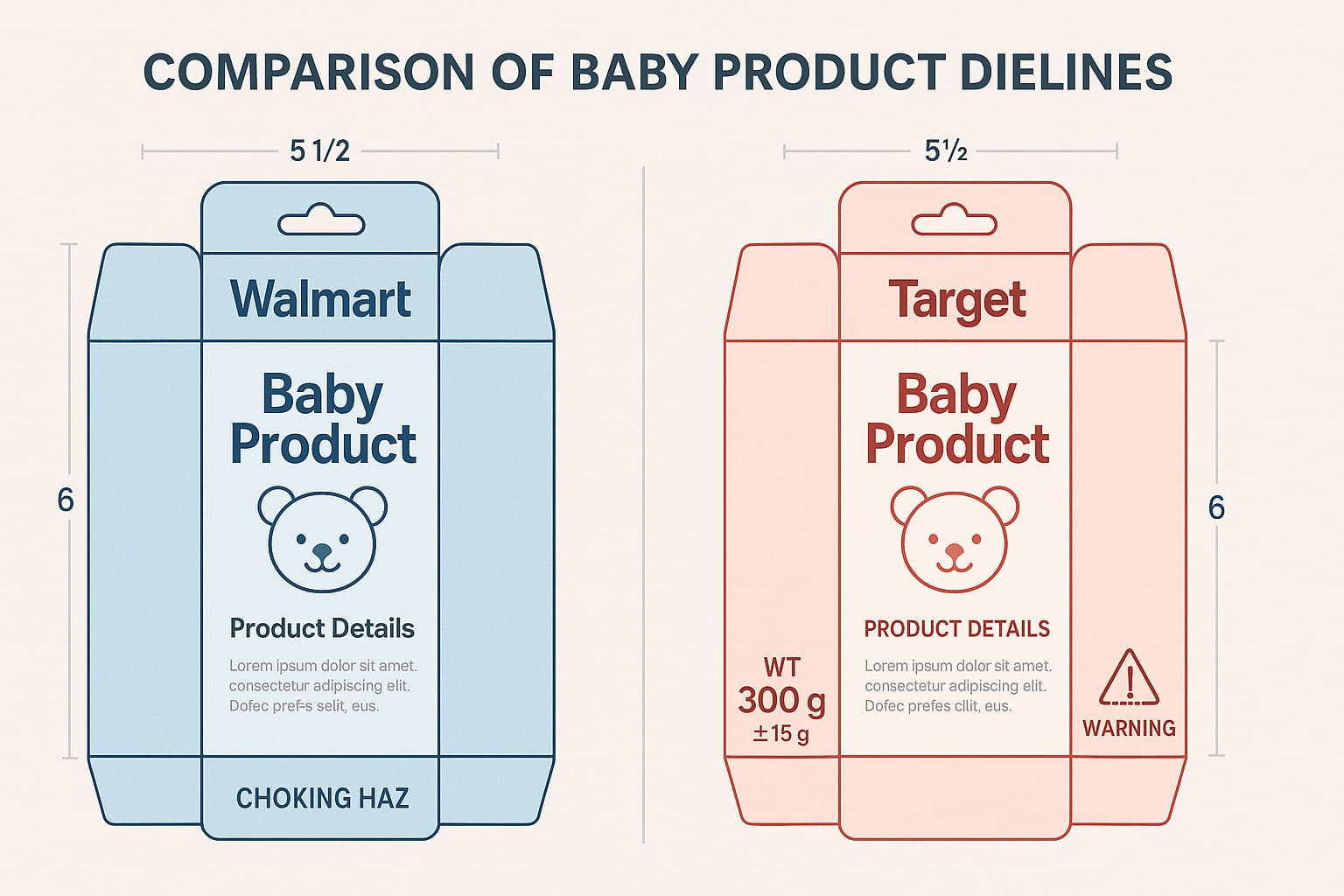

沃尔玛和Target的美国市场的婴儿过道产品的关键二线规格是什么?

沃尔玛和目标具有每个包装设计必须遵守的特定二线要求。这些规格对于获得这些零售商而言是不可商品的。那么,对于婴儿过道产品,您需要牢记哪些关键二线规格?

沃尔玛(Walmart)和目标需要特定的Dieline规格,以包装,其中包括精确的尺寸,重量容忍度和安全功能。了解其确切规格对于确保可以在商店中出售婴儿产品至关重要。

在美国,沃尔玛和Target的包装要求7是一丝不苟的。两家零售商都非常了解如何在其货架上呈现产品。例如,它们可能需要包装的一定尺寸范围,以确保产品整齐地适合显示单元。此外,包装必须能够承受运输的严格性,这意味着您需要用材料强度9和重量分布来二线8

沃尔玛和Target的婴儿产品的关键规格

这是沃尔玛(Walmart)和婴儿过道产品(Baby Aisle Products)所需的一些关键二线规格的快速指南:

| 规格 | 沃尔玛的要求 | 目标要求 |

|---|---|---|

| 方面 | 架子和地板显示的特定尺寸 | 类似的维度,但可能会根据类别而有所不同 |

| 条形码放置10 | 条形码放置必须清晰易于扫描 | 条形码放置不应与设计元素重叠 |

| 体重耐受性11 | 必须承受无损害的处理和堆叠 | 运输和展示所需的类似重量容忍度 |

| 物质规格12 | 纸板强度必须足以体重和运输 | 材料强度对于确保产品的到来完好无损也至关重要 |

| 打印质量 | 印刷应该锋利耐用 | 高级演示所需的高质量打印 |

双人市场成功:如何为我们和澳大利亚婴儿产品合规优化包装设计?

设计符合美国和澳大利亚法规的包装似乎是一项艰巨的任务,但采用正确的方法是完全有可能的。诀窍在于了解每个市场要求的精细印刷品,并确保您的包装设计与它们相遇而不会损害您的产品的吸引力。

为美国和澳大利亚的合规性优化您的包装设计涉及了解每个市场标准的细微差别,并相应地调整设计以维持产品完整性和吸引力。

为了优化美国和澳大利亚市场的包装设计13 法规合规性14和视觉吸引力之间取得平衡。首先彻底研究每个市场的特定法规。沃尔玛和塔吉特在美国都有严格的规则,尤其是在婴儿产品的耐用性和标签方面。在澳大利亚,环境考虑15和双语标签也是方程式的重要组成部分。

跨市场优化包装设计的策略

- 了解监管差异:如前所述,在安全标准,标签和包装材料方面,美国和澳大利亚有不同的要求。了解这些差异对于确保合规至关重要。

- 尽早与零售商合作:在完成包装设计之前,最好与沃尔玛和Target这样的零售商进行交流,以确保您的设计达到他们的期望。在澳大利亚,与当地零售商接触将有助于避免昂贵的延误。

- 创建模块化二线:考虑设计一个模块化二线16允许根据您针对的特定市场进行轻松修改。从长远来看,这种方法可以节省时间并降低成本。

- 本地偏好的因素:除了监管要求之外,请注意每个市场中的消费者偏好。例如,澳大利亚消费者可能更喜欢环保包装17 ,而美国消费者可能会优先考虑便利。

避免昂贵的延误:沃尔玛和Target对婴儿配件的Dieline要求是什么?

如果您正在为婴儿配件设计包装,无论是瓶子,尿布还是其他必要物品,则需要确保量身定制二氧化碳以满足沃尔玛和Target的确切规格。包装不合规引起的延迟可能会昂贵,并延迟您的产品发布。

为了避免昂贵的延误,您需要充分了解沃尔玛和目标婴儿配件的Dieline要求。适当的准备和合规性将简化流程并确保及时交付。

沃尔玛和Target对婴儿配件18的是明确的。他们期望包装不仅耐用和保护性,而且对消费者也有吸引力19 。您的包装必须符合物理和审美标准。无论您是为婴儿湿巾设计20还是为婴儿玩具设计的塑料容器,都必须考虑包装的重量,形状和整体稳定性。

避免延迟:婴儿配件包装的最佳实践

- 尽早确保合规:不要等到最后一刻检查您的包装是否符合所需的标准。在进行生产之前,请与零售商确认您的二线。

- 选择健壮的材料:婴儿配件通常很脆弱,因此使用强大的材料是必不可少的。沃尔玛和目标都需要包装,以承受处理,存储和运输的包装而不会造成损坏。

- 验证条形码放置包装设计的通常被忽视的元素21 。确保条形码可扫描,并遵守沃尔玛和Target的规格,以避免处理任何延迟。

- 进行测试:在大规模生产之前,进行测试以确保您的包装可以处理运输和零售显示的压力。

设计地板架搭档:如何与美国零售商标准和澳大利亚法规保持一致?

地板式搭档通常用于在零售店中展示婴儿产品,但它们需要满足特定要求才能成功。在美国,沃尔玛和目标等零售商的尺寸和重量限制为22 ,以确保它们不太笨重或不稳定。澳大利亚,相同的原则适用,但零售商可能对材料和设计美学的。

在设计地板式搭档时,重要的是要了解我们和澳大利亚零售商对尺寸,耐用性和美学的要求。确保您的显示器在达到这些标准时脱颖而出是成功的关键。

地板式搭档通常用于在零售店中展示婴儿产品,但它们需要满足特定要求才能成功。在美国,像沃尔玛和Target这样的零售商具有地板显示器的尺寸和重量限制,以确保它们不太笨重或不稳定。在澳大利亚,相同的原则适用,但是零售商可能对材料和设计美学的偏好略有不同。

地板架显示的主要注意事项

- 尺寸和重量限制25 :美国和澳大利亚零售商都对地板架显示器的尺寸和重量都有限制。确保您的设计适合所需的尺寸,并且不会超过重量的容忍度。

- 材料和耐用性26 :使用高质量的材料,可以承受在商店周围移动的磨损。在这两个市场中,零售商都希望这些展示保持稳定和完整。

- 设计吸引力27 :您的地板显示器应在视觉上吸引吸引客户。鲜艳的色彩,大胆的排版和干净的布局是产生影响的关键。

结论

设计双人市场婴儿产品的包装二环线是监管合规性和设计美学之间的平衡行为。通过了解沃尔玛,目标和澳大利亚零售商的特定需求,您可以创建适合两个市场的包装,而不会损害质量或吸引力。

了解CPSC指南对于在美国市场的遵守情况至关重要,确保产品安全性和适当的标签。 ↩

熟悉ACCC法规对于符合澳大利亚标准,尤其是婴儿产品至关重要。 ↩

探索标签要求有助于确保您的产品符合美国和澳大利亚市场标准,从而避免法律问题。 ↩

了解标签要求对于两个地区的合规性和市场接受至关重要。 ↩

探索耐用性标准可以帮助确保您的产品安全到达并满足客户期望。 ↩

了解首选材料可以增强产品在澳大利亚市场上的吸引力和可持续性。 ↩

了解这些要求可以帮助您设计符合零售商标准的产品,从而确保更好的架子表现和销售。 ↩

了解Dielines将提高您的包装设计技能,确保您的产品既实用又具有视觉吸引力。 ↩

探索此主题将提供有关创建可以承受运输和处理的耐用包装的见解。 ↩

了解条形码放置可以提高产品可见性和扫描效率,这对于零售成功至关重要。 ↩

了解体重容忍度有助于确保您的产品安全处理和运输,从而减少损坏和回报。 ↩

选择合适的材料对于产品完整性和安全至关重要,尤其是在婴儿产品市场上。 ↩

探索包装设计中的最佳实践可以帮助您为美国和澳大利亚市场创建有效且合规的包装。 ↩

了解法规合规性对于避免法律问题并确保您的产品符合市场标准至关重要。 ↩

了解环境考虑可以增强您的包装策略,并吸引澳大利亚的生态意识消费者。 ↩

模块化二线可以简化您的设计过程并降低成本。发现有关其在包装设计中的好处的更多信息。 ↩

环保包装对消费者越来越重要。了解它为什么重要以及如何增强品牌的吸引力。 ↩

了解这些要求可以帮助您设计符合零售标准并吸引消费者的包装。 ↩

探索在包装设计中平衡耐用性和美学的策略,对婴儿产品至关重要。 ↩

了解专门针对婴儿湿巾包装的有效设计实践,以增强市场吸引力。 ↩

该资源将提供有关符合零售标准并增强产品吸引力的有效包装设计的见解。 ↩

了解尺寸和重量限制可以指导您设计符合零售商标准的合规性和有效零售显示。 ↩

了解对地板展示的要求可以帮助您创建有效的零售策略,以吸引客户并增强产品可见性。 ↩

探索设计美学可以提供有关创建视觉上吸引人的显示器的见解,从而引起不同市场的客户的共鸣。 ↩

了解这些限制对于在零售环境中的合规性和有效的显示设计至关重要。 ↩

探索最佳材料可以提高展示的寿命和有效性,从而确保它们承受零售条件。 ↩

学习设计策略,以吸引客户并通过有效的视觉商品促进销售。 ↩