I sell in crowded aisles. I fight for every second of attention. I need packaging that works hard, moves fast, and costs less than it earns.

Use customized cardboard boxes to boost shelf impact, protect products, cut shipping weight, speed launches, and meet sustainability goals. Custom sizes and prints reduce damage and waste, improve brand recall, and fit retailer rules without extra fillers or labor.

I will show what matters. I will answer the four key questions. I will keep it practical and data-aware from the display industry.

What are the benefits of custom boxes?

I need boxes that fit my product and my plan. Standard sizes waste space and budget. Custom boxes fix that.

Custom boxes reduce material and freight costs, improve protection, and raise conversion with brand-right graphics. They pack faster, stack cleaner, and meet retailer specs, which lowers chargebacks.

Where custom boxes1 win in the real world

I run PopDisplay in Shenzhen. I work with U.S. buyers on seasonal launches. I learned this the hard way when a national chain cut our end-cap space by 10%. Our standard cartons no longer fit the plan. We rebuilt the shipper PDQ to exact shelf width and height. We shaved 14% void fill, gained one extra facings row, and lifted unit sales in week one. This is not luck. This is fit.\

Now I plan benefits in four lanes:

| Benefit | What it means | How I measure | Typical lift |

|---|---|---|---|

| Cost fit | Right-size die-lines, less board, less air | Material per unit; freight per pallet | 5–15% material; 8–20% freight |

| Protection | Inserts tuned to SKUs | Drop/ISTAmethod passes; return rate | Return rate ↓ 20–40% |

| Speed | Flat-pack, tool-less locks | Assembly minutes in store/DC | Set time ↓ 30–50% |

| Brand | Print hits, substrate tone | A/B on shelf conversion | +5–25% conversion |

I keep the design simple. I use single-wall corrugated2 for most POP shippers. I switch to reinforced edges only where load tests demand it. I align dielines with digital print so small runs stay viable. I choose water-based inks because many buyers now require them. I lock every claim to a test: drop, vibration, stack. When I do this, my customers reorder. That is the main benefit that pays for everything.

What are the advantages of cardboard box packaging?

I choose cardboard because it balances price, print, and eco goals. Other materials rarely do all three at once.

Cardboard offers low cost per impression, fast lead times, wide print freedom, and strong sustainability credentials. It is light, recyclable, easy to cut and fold, and proven across retail and e-commerce.

Why cardboard beats other options for retail and e-commerce

The display market grows with simple rules. Brands want speed, looks, and a clean footprint. Cardboard gives me all three. North America is mature and stable. Asia-Pacific grows fast with urban retail and e-commerce. Europe pushes sustainability. These forces reward paper-based packaging3. My factory follows this by keeping three production lines flexible. One runs short digital jobs. One runs longer flexo jobs. One handles die-cut and glue.\

I keep a scorecard by use case:

| Use Case | Cardboard Edge | What I specify | Risk to watch |

|---|---|---|---|

| Club PDQ (Costco) | Pallet-ready, quick shop | Double-wall outer + litho top | Overprint scuff |

| Drug/Beauty | Fine print and color | Coated top liner, 175–200 gsm | Color shift under LED |

| D2C Shipper | Light, exact fit | E-flute / B-flute4 | Tape tear; porch weather |

| Outdoor gear promo | Rugged look + recycle | Kraft liner, water-based ink | Humidity warp |

I test strength and print before mass production. I keep assembly steps low because store labor is tight. I use QR or NFC only when the story needs it. I avoid plastics where possible because many buyers dislike mixed materials. Cardboard wins here because it separates cleanly in recycling. This is why it remains the default for fast launches and broad distribution.

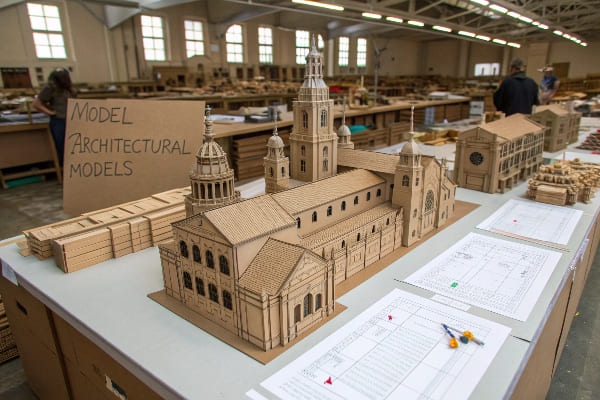

What are the advantages of using cardboard as a modelling material?

I prototype with cardboard because it moves from idea to shelf in days. I can fail fast without high cost.

Cardboard is easy to cut, crease, and glue, so teams can prototype structures quickly, test load, and refine ergonomics before investing in tooling. It supports digital print for rapid visual tests.

How cardboard modeling5 accelerates design-to-launch6

When a U.S. hunting brand asked for a crossbow launch PDQ, time was short. The buyer wanted a floor display that held real weight, told a clear safety story, and passed pallet moves. We built three cardboard mockups in two days. We tweaked angles so grips did not snag. We doubled the base tabs and added a hidden spine. The final load test passed with margin. We hit the deadline.

I manage modeling with a simple framework:

| Step | Goal | Tools | Output |

|---|---|---|---|

| Rough mock | Validate footprint | Knife, ruler, sample board | Scale feel, hand reach |

| Beta mock | Prove load path | Crease wheel, hot glue | Weight test, wobble fix |

| Print test | Check graphics | Digital press swatches | Brand color, legibility |

| Transit sim | Survive supply chain | Vibration/stack trials | Pass/Fail with notes |

I choose single-wall for hand models and upgrade to double-wall for heavy SKUs. I use living hinges and tab locks to cut screws. I set tolerance at the start. I mark every stress point with tape during tests. I remove flair that slows assembly. Cardboard modeling makes this easy because changes are cheap. This is how I keep launches on time without gambling on unproven plastics or metal.

Why is cardboard packaging better?

I call cardboard “better” when it meets goals that matter: cost, speed, sustainability, and sell-through. It does this more often than other materials.

Cardboard is better because it balances price, performance, and sustainability. It reduces CO₂ in shipping, supports full-color branding, meets recycling goals, and adapts fast to retailer rules and seasonal demand.

The balanced score that makes cardboard the safer bet

I compare materials with one scoreboard. I use it with buyers who want proof, not hype. The scoreboard tracks carbon, cost, print, protection, and lead time7. Cardboard wins most mixed scenarios. Metal and plastics can last longer, but they cost more, ship heavier, and need extra parts. In fast retail, that hurts margins and timing. In Europe, recycling rules get tighter every year. In the U.S. and Canada, big retailers flag mixed-material displays. Asia-Pacific grows fast and rewards speed. Cardboard fits all three realities.\

Here is the simple view:

| Criterion | Cardboard | Plastic | Metal |

|---|---|---|---|

| Unit cost | Low | Medium | High |

| Lead time | Short | Medium | Long |

| Print quality | High | Medium | Low |

| Recyclability | High | Low–Medium | Medium |

| Shipping weight | Low | Medium | High |

| Modularity | High | Medium | Medium |

I still respect limits. Moisture ruins weak board. I use nano or water-based coatings only when tests prove recyclability8. I avoid glossy laminates that block recycling streams. I lock suppliers with FSC and factory audits. I design flat-pack to cut freight and damage. I plan color with simple palettes to avoid mismatches under store lights. When I follow these rules, cardboard is not only better. It is safer for deadlines and margins.

Conclusion

Custom cardboard boxes give me fit, speed, savings, and a cleaner footprint. They help me launch faster, sell more, and keep promises to buyers and the planet.

Explore how custom boxes can enhance product presentation and reduce costs, making them a smart choice for businesses. ↩

Learn about single-wall corrugated’s advantages in cost-effectiveness and protection for your products. ↩

Explore this link to understand how paper-based packaging enhances sustainability and meets consumer demands. ↩

Learn about E-flute and B-flute to make informed choices for lightweight and efficient packaging solutions. ↩

Explore how cardboard modeling can streamline your design process and reduce costs, making it a valuable tool for rapid prototyping. ↩

Learn effective strategies to enhance your design-to-launch process, ensuring timely and successful product releases. ↩

Exploring lead time insights can enhance your understanding of logistics and improve your business operations. ↩

Understanding recyclability can help you make informed choices about sustainable packaging options. ↩