Many businesses rely on corrugated displays for showcasing products in an eye-catching way. But which types are available, and how do they stand out in the market? Understanding these options is key to selecting the right display fixture for your needs.

Corrugated fixtures come in a variety of types, each designed to meet specific business and product display requirements. These fixtures can be fully customized to match branding needs and offer robust functionality.

Corrugated displays are widely used in retail environments, trade shows, and exhibitions due to their lightweight, eco-friendly nature. The flexibility in design and structure allows businesses to showcase products in creative and engaging ways. But what types of corrugated fixtures are available? Let’s explore this further.

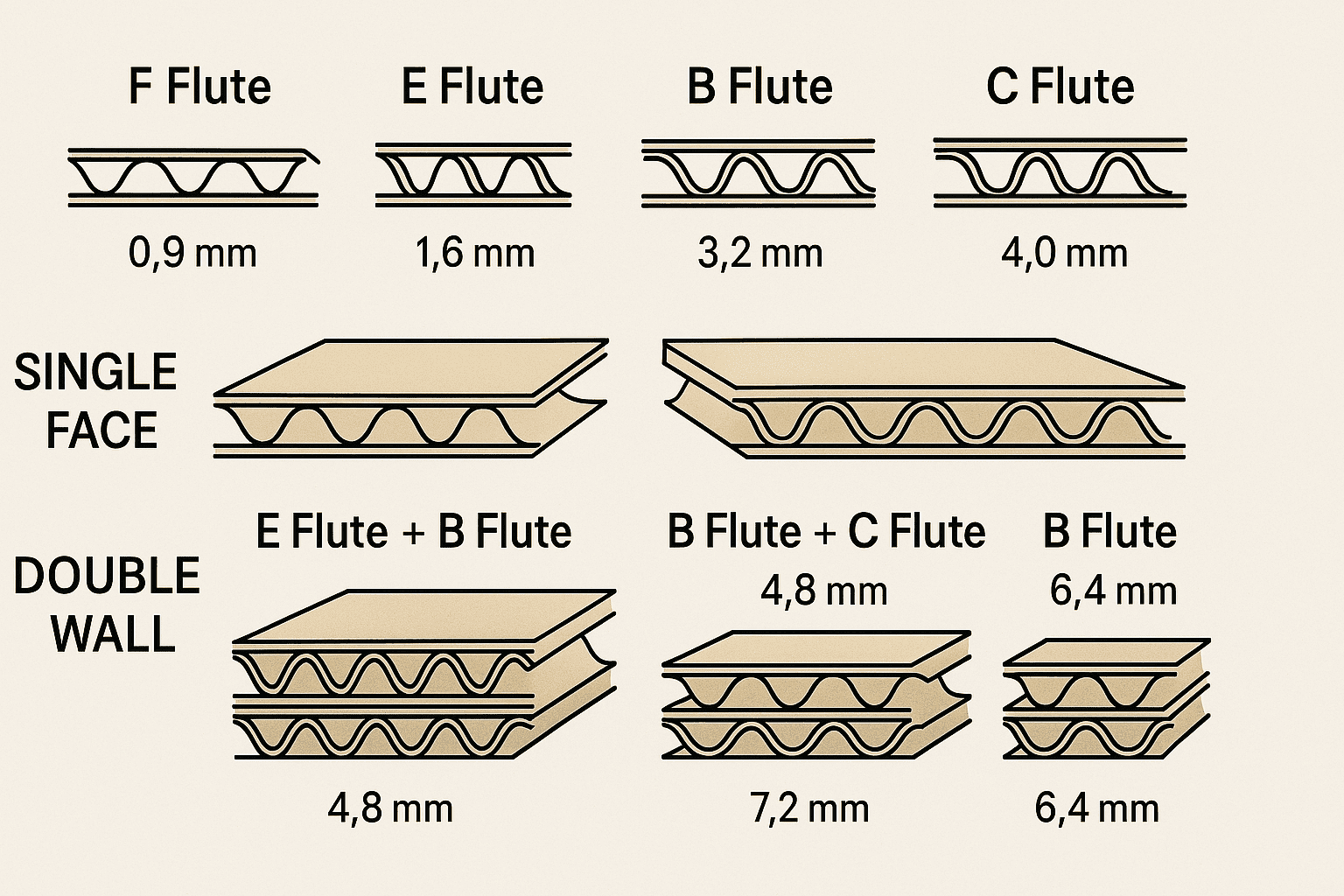

How many types of corrugated are there?

When it comes to corrugated displays, there are several options available, each serving a different purpose. Understanding these types will help you choose the most suitable one for your needs.

There are two main types of corrugated board: single-wall and double-wall. Each type provides varying levels of strength and durability, with double-wall being ideal for heavy-duty applications and single-wall suited for lighter, cost-effective displays.

Single-Wall Corrugated

Single-wall corrugated1 displays are made with one layer of flute material between two layers of paper. These displays are lightweight and cost-effective2, making them ideal for less heavy-duty applications. They are commonly used for packaging or lightweight display fixtures3.

Double-Wall Corrugated

Double-wall corrugated1 displays consist of two layers of flute material, offering extra strength and durability2. These displays are perfect for heavier items or for use in environments where the display will endure more wear and tear. They are also used when a higher level of protection3 is needed during transport or storage.

Other Variants

Beyond the basic single-wall and double-wall options, there are also variations like triple-wall corrugated boards4, which are used for extremely heavy-duty applications5. However, they are less common for general retail displays but might be used in industrial or logistical contexts6.

What is a corrugated display?

A corrugated display is a fixture made from corrugated board, which is a material consisting of a layer of fluted paper between two flat layers. This type of display is often used to present products in retail environments, trade shows, or promotional settings.

A corrugated display is a type of marketing tool that uses cardboard to showcase products. These displays are designed to be sturdy, lightweight, and easily customizable, offering a versatile solution for businesses looking to grab customer attention.

Key Features of Corrugated Displays

Corrugated displays are known for their lightweight and eco-friendly nature7. They can be designed in various shapes and sizes, from simple shelves to more complex, interactive setups8. They also offer excellent print quality9, allowing businesses to showcase their branding, logos, and other marketing materials effectively.

Why Businesses Use Corrugated Displays

One of the primary reasons businesses choose corrugated displays is because they are cost-effective10. They also offer a high degree of customization11, making it easier to create displays that align with a company’s brand identity. Additionally, their ease of transport and setup12 makes them perfect for short-term and temporary promotions.

What are examples of corrugated materials?

Corrugated materials are versatile and can be used in many different ways. These materials are typically chosen based on their strength and durability, as well as the specific needs of the display or packaging.

Examples of corrugated materials include kraft paper, white paper, and printed paper. These materials can vary in thickness and strength depending on the needs of the display, and they are commonly used in the production of retail fixtures, packaging, and even signage.

Types of Corrugated Materials

- Kraft Paper13: Known for its strength and natural look, kraft paper is commonly used for displays and packaging. It is an eco-friendly material and can be easily recycled.

- White Paper14: White corrugated paper is often used for displays that require high-quality printing. This material provides a clean background for vibrant colors and images.

- Printed Paper15: Printed corrugated board offers the flexibility to showcase vibrant graphics, logos, and branding. This type of material is used when you need to capture attention and communicate specific marketing messages.

Material Selection16 for Display Fixtures

Choosing the right material for your display fixture17 depends on the type of products you plan to showcase and the durability required18. For example, heavier products may require a thicker material, while lighter, smaller products can be displayed on thinner, more affordable boards.

What is the most common type of corrugated board?

The most commonly used type of corrugated board in retail and display fixtures is the single-wall board. This is because it strikes a good balance between cost and strength, making it ideal for a variety of products.

The most common type of corrugated board is the single-wall board, made up of one layer of fluted paper between two flat paper layers. It is widely used in both packaging and retail display applications due to its balance of affordability and strength.

Why Single-Wall Corrugated is Popular

Single-wall corrugated19 board is the most commonly used material because of its lightweight and cost-effective20 nature. It can handle medium-weight products21, making it perfect for most retail and display needs. Additionally, single-wall corrugated displays are easy to ship and set up, making them an attractive option for businesses looking for a hassle-free solution.

The Benefits of Single-Wall Corrugated Displays

The primary benefits of single-wall corrugated displays include:

- Cost-Effectiveness22: Single-wall board is affordable compared to double or triple-wall materials.

- Lightweight23: Easy to transport and handle during setup.

- Customizable24: Can be easily printed on, allowing businesses to create eye-catching designs that align with their branding.

Conclusion

Understanding the different types of corrugated fixtures is crucial for choosing the right display solution for your business. Whether you need a lightweight, cost-effective option or a heavy-duty display, there’s a corrugated fixture for every need. By selecting the correct type, you can ensure your products are presented in the most effective way possible.

Explore the advantages of Single-wall corrugated displays for packaging and lightweight fixtures, enhancing your understanding of their applications. ↩ ↩

Discover the factors that contribute to cost-effective packaging solutions, helping you make informed choices for your projects. ↩ ↩

Learn about the manufacturing process of lightweight display fixtures to understand their design and functionality better. ↩ ↩

Explore this link to understand the unique applications and benefits of triple-wall corrugated boards in various industries. ↩

Discover how heavy-duty applications utilize specialized packaging materials to enhance durability and performance. ↩

Learn about the distinct requirements and solutions for packaging in industrial versus logistical settings. ↩

Exploring eco-friendly packaging solutions can enhance your understanding of sustainable practices and their impact on the environment. ↩

Discovering the benefits of interactive displays can provide insights into engaging customers and enhancing their experience with your brand. ↩

Understanding the importance of print quality can help you create more effective marketing materials that capture attention and convey your brand message. ↩

Discover how corrugated displays can save businesses money while enhancing their marketing efforts. ↩

Learn how customization can elevate your brand’s visibility and appeal through unique display designs. ↩

Explore the advantages of quick setup and transport for promotional events and temporary displays. ↩

Explore the advantages of Kraft Paper, including its eco-friendliness and strength, to enhance your packaging solutions. ↩

Discover why White Paper is ideal for vibrant displays and how it can elevate your marketing materials. ↩

Learn how Printed Paper can effectively showcase your brand and attract attention with its vibrant graphics. ↩

Understanding material selection is crucial for creating effective and durable display fixtures. Explore this link for expert insights. ↩

Learn about the essential factors in designing display fixtures to enhance product visibility and durability. This resource is invaluable. ↩

Discover how durability impacts material selection for display fixtures, ensuring your displays last longer and perform better. ↩

Explore the advantages of Single-wall corrugated board to understand why it’s a preferred choice for packaging and displays. ↩

Learn about the significance of lightweight and cost-effective packaging solutions in today’s market. ↩

Discover what qualifies as medium-weight products and how they influence packaging choices. ↩

Exploring this link will provide insights into how cost-effective packaging can enhance your business strategy. ↩

Understanding the significance of lightweight packaging can help optimize logistics and reduce shipping costs. ↩

Discover how customizable packaging can elevate your brand’s presence and attract more customers. ↩