What is Corrugated Cardboard?

I see brands fight for attention at retail. Shoppers rush by. Displays must work fast. Costs must stay low. I face this every season, so I test and learn every week.

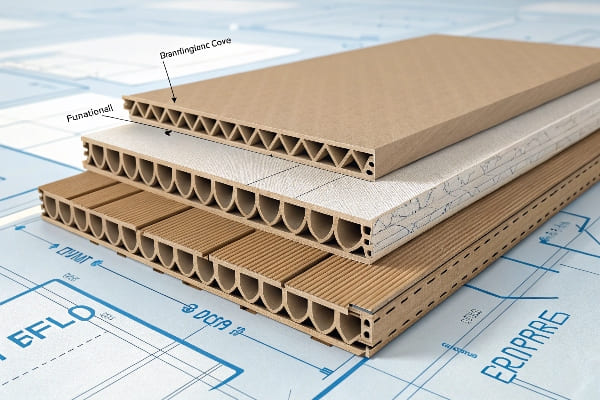

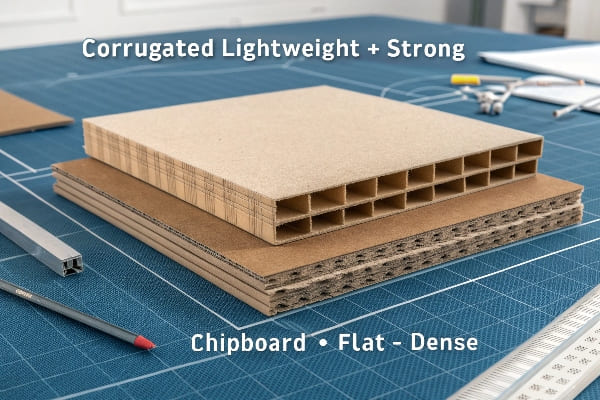

Corrugated cardboard is a strong sandwich of a wavy fluted sheet glued between flat linerboards; regular cardboard (paperboard) is a single, solid sheet used for cereal boxes and sleeves, not for heavy shipping or load-bearing displays.

I will keep this simple and useful. I will answer fast first, then I will dig deeper with clear tables and short points. I will also add one short story from my factory floor to show real tradeoffs.

What is the difference between corrugated cardboard and regular cardboard?

I meet many buyers who mix up the two. I used to do that too. The words sound close. The uses are not close. The wrong choice breaks budgets.

Corrugated cardboard uses a fluted core between two liners for strength and cushioning, while regular cardboard (paperboard) is a single flat sheet for light packaging; corrugated suits shipping and displays, paperboard suits cartons and sleeves.

Structure and Strength

I start with the build. Corrugated has three parts. I have two flat liners and one wavy medium. The glue joins them. The air inside the waves adds stiffness and shock control. Paperboard has one flat sheet. It folds cleanly. It prints very well. It has low crush strength.

Use Cases and Cost

When I choose for displays, I use corrugated1 for floor units, pallet displays, and PDQ trays that carry weight. I use paperboard2 for sleeves, light trays, and small counter toppers that do not hold weight. Corrugated costs a bit more per square meter than thin paperboard, but I get load capacity, stack height, and better survival in transit. The right choice lowers returns.

| Factor | Corrugated Cardboard | Regular Cardboard (Paperboard) | What I do |

|---|---|---|---|

| Structure | Flute + liners | Single ply | Match to load |

| Typical Thickness | 2–7 mm (E/B/C/BC) | 0.3–1.0 mm | Fit to product |

| Strength Tests | ECT, BCT, burst | Caliper, stiffness | Ask for data |

| Best For | Shipping, floor POP | Cartons, sleeves | Mix both |

| Great with litho-lam/digital | Excellent direct | Pick by artwork | |

| Cost vs Value | Higher but durable | Lower but limited | Balance ROI |

I learned this the hard way. A client pushed paperboard for a tall arch display to save cost. The arch leaned after one weekend. We rebuilt in B-flute corrugated with the same print. Sales rose, and the unit lasted all season.

What counts as corrugated cardboard?

Some buyers ask if any thick board is corrugated. Thickness is not the only sign. The internal wave is the key. I always check the edge.

Corrugated cardboard includes any paperboard made of at least one fluted medium bonded to one or two liners (single-face, single-wall, double-wall, or triple-wall); the flute profile (E, B, C, etc.) and liner weight define performance.

Types You Will See

Corrugated comes in clear families. Single-face has one liner and one exposed flute. I use it for cushion wraps or luxury sleeves. Single-wall has two liners and one flute; this is my daily workhorse for most displays. Double-wall stacks two flutes and three liners; I use it for heavy products and tall towers. Triple-wall is rare for displays but great for very heavy gear.

Flute Choices and Display Fit

I match flute to need. E-flute prints clean graphics and folds well, so I like it for counter units. B-flute gives good crush strength for trays. C-flute adds cushioning for shipping. BC double-wall carries weight for pallet displays. Surface choice matters, too. I run kraft liner for strength and white top for bright print. If a client wants high ink holdout, I add a litho label or use coated white liner.

| Corrugated Type | Flute Profile | Typical Use | Why I pick it |

|---|---|---|---|

| Single-Face | Any + one liner | Cushion wraps, sleeves | Flex and protection |

| Single-Wall3 | E/B/C | Counter, shelf, floor POP | Balance of print and strength |

| Double-Wall | BC/EB | Pallet displays, towers | Load and stability |

| Triple-Wall | AAA etc. | Industrial crates | Extreme loads |

I also check sustainability needs4. I can specify recycled content for the medium and liners. I can keep water-based inks and glues. I can keep coatings recyclable. This helps procurement teams meet goals without losing strength.

What is an example of a corrugated cardboard?

People learn fast with examples. I keep samples on my desk. I pull one when I explain load ratings. Stories make specs real.

A common example is a single-wall B-flute corrugated shipping box or a retail floor display made from E-flute printed sheets laminated to kraft liners; both use a fluted core between liners for strength.

Real Display Example From My Floor

I built a floor display for hunting accessories. The buyer needed 40 packs per unit. Each pack weighed 0.7 lb. The total live load was 28 lb plus the structure. I selected BC double-wall5 for the base and shelves. I used E-flute6 for headers and side wings to keep sharp print. I applied water-based varnish to resist scuffs. I ran edge crush tests on samples and then did a simple box compression test with load bags. The unit passed a 72-hour lean test on a slightly uneven floor.

Why This Example Works

This unit shows how I layer materials. Heavy parts use BC for stiffness. Graphic parts use E for print. The mix keeps cost in line and holds weight. It ships flat. Two people can set it up in five minutes with no tools. The buyer hit a tight launch date. The store team liked the quick setup and clear planogram.

| Component | Material | Purpose | Note |

|---|---|---|---|

| Base and shelves | BC double-wall | Load and stability | Fewer braces needed |

| Header and wings | E-flute with white top | High print quality | Clean edges |

| Back panel | B-flute | Shear resistance | Simple locks |

| Finish | Water-based varnish | Scuff control | Recyclable path |

I use this pattern in sporting goods, personal care, and snacks. It scales up or down. It also travels well on pallets and survives cross-dock moves.

How do I know if a box is corrugated?

Teams often ask for a quick field check. Tools help, but I like simple steps first. I teach this to new staff on day one.

Look at the cut edge for a wavy flute between flat liners; press the panel and feel ridges; read specs for ECT or flute code; if you see a single solid sheet with no waves, it is paperboard.

Fast Checks I Use On Site

I start with the edge. I tilt the panel toward light and find the waves. I pinch the face and listen; corrugated feels springy and sounds crisp. Paperboard feels flat and dull. I look for print like “32 ECT7” or “B-Flute” near a seam. I measure thickness with a simple caliper. Anything around 2–4 mm is likely E or B. I try a thumb press near a corner. Corrugated pushes back more.

When I Need Proof

If the order is big, I ask for lab data. I ask for ECT, burst, and board grade. I also run a small stack test8. I load a sample box with sandbags and add a top load to simulate pallet stack. I check lean after 24 hours. I take photos and share results with the buyer so that we can agree on safety margins. This routine avoids late surprises and protects peak season launches.

| Field Step | What I do | What it tells me |

|---|---|---|

| Edge view | Look for flute waves | Confirms corrugated |

| Thumb press | Feel spring and ridges | Quick stiffness cue |

| Label read | Find ECT/flute code | Board grade hint |

| Caliper | Check thickness | Likely flute type |

| Stack test | 24-hour load | Real-world margin |

I learned to keep a small kit in my bag: a caliper, a pocket scale, and a tape. This kit has saved me many calls and many shipments.

Conclusion

Corrugated is a fluted core between liners. Paperboard is a single sheet. I match type, flute, and finish to weight, print, and budget so displays work and last.

Explore the advantages of corrugated cardboard, including its strength and durability for various display applications. ↩

Learn about paperboard’s applications and its limitations, helping you make informed choices for lightweight packaging solutions. ↩

Explore this link to understand why Single-Wall is a preferred choice for balance between print quality and strength in displays. ↩

Discover strategies to incorporate sustainability in packaging, ensuring strength while meeting eco-friendly goals. ↩

Explore this link to understand the benefits of BC double-wall material in creating sturdy and effective displays. ↩

Discover why E-flute is favored for its print quality and lightweight properties, enhancing your display designs. ↩

Understanding ECT is crucial for evaluating the strength and durability of corrugated materials, ensuring your packaging meets safety standards. ↩

Learning about stack tests can help you assess the real-world performance of your packaging, preventing costly surprises during shipping. ↩