I see corrugated boxes every day in my factory. I also ship thousands of cardboard displays in them. Many buyers ask the same simple question. I will answer it here.

A corrugated box is a shipping or retail container made from fluted paper sandwiched between flat linerboards; it is stronger than plain cardboard, lightweight, recyclable, and customizable for size, print, and strength.

I will keep things clear and short. I will also show how I choose materials, how I verify sizes, and how I avoid common mistakes. You can use my notes in real projects.

What is the difference between a cardboard box and a corrugated box?

Many people say "cardboard" for all paper boxes. I did that when I started. In my first year, a client lost money because I shipped items in wrong board.

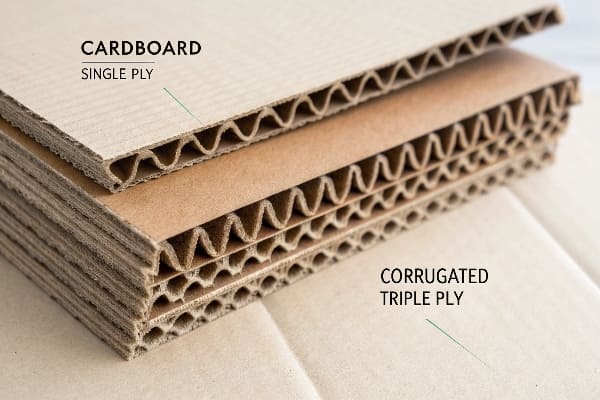

Cardboard is solid paperboard with no flutes, while corrugated has a wavy fluted medium between liners; corrugated is stronger, better for shipping, and easier to engineer for load, stacking, and cost.

Strength, cost, and use cases

I use simple rules in my plant. I pick corrugated for weight, impact, and stacking. I pick paperboard for small retail cartons and sleeves. The key is the flute. The flute acts like a tiny I-beam. It resists crush, drops, and vibration. Single-wall boards work for most displays and PDQ trays. Double-wall carries big, heavy kits, like crossbow bundles or seasonal pallet displays. Triple-wall is rare, but it saves exports in rough routes. I also match liners. Kraft liners1 handle humidity better than white clay-coated liners. White prints better for brand color. I run tests on edge crush (ECT)2 and burst. I simulate warehouse stacks with a safety factor of 5–7 days in hot rooms. This habit came from a failed delivery to a high-traffic retailer. That order leaned on the floor and bent. I learned to treat stacking like a science, not a guess.

Quick matrix of options

| Item | Paperboard (Cardboard) | Corrugated Single-Wall | Corrugated Double-Wall |

|---|---|---|---|

| Typical thickness | 0.3–0.6 mm | 2–5 mm | 5–9 mm |

| Flute | None | One medium | Two media |

| Best for | Small cartons, sleeves | Shipper boxes, PDQ trays | Heavy kits, pallet displays |

| Print look | Very clean | Clean | Good |

| Cost vs strength | Low, low strength | Medium, high value | Higher, very strong |

What makes a box corrugated?

People often point at any brown box and call it corrugated. That is close, but not exact. The secret sits in the cross-section.

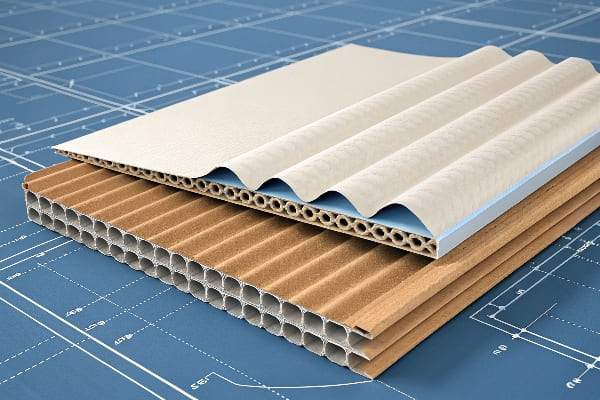

A box is corrugated when a fluted paper medium is glued between one or two linerboards; flute profile (A, B, C, E, F), wall count, and liners define strength and performance.

Layers, flutes, and walls that matter

I build the board from three parts. The medium forms the flute. The liners sit outside. Heat and starch glue bond them. Flute height and pitch set cushioning and compression. A-flute is tall and cushions drops. B-flute is thin and resists crush. C-flute is the all-rounder for shippers. E-flute3 is thin and prints well for retail. F-flute is even finer for luxury packs. Most display trays use E- or B-flute for neat edges. Most outer shippers use C-flute. When loads grow, I stack walls: single-wall, double-wall, or triple-wall. I also pick paper weights. I can combine recycled liners4 for cost and sustainability with virgin kraft for edges and humidity. I choose water-based inks and glues for retail safety. These choices align with big buyers in the U.S., Canada, and Europe. They ask for FSC, recycling claims, and low VOC inks. In my shop, I mark each spec on the die-line, so the production team cannot swap materials later to save pennies. That step prevents weak corners and collapse in transit.

Common flute choices I use

| Flute | Thickness (approx) | Best trait | Typical use |

|---|---|---|---|

| A | 4.8 mm | Cushion | Fragile goods |

| B | 3.2 mm | Crush | Food trays, trays under displays |

| C | 4.0 mm | Balance | Standard shippers |

| E | 1.6 mm | Retail cartons, PDQ | |

| F | 0.8–1.2 mm | Fine detail | Premium sleeves |

How to measure corrugated box size?

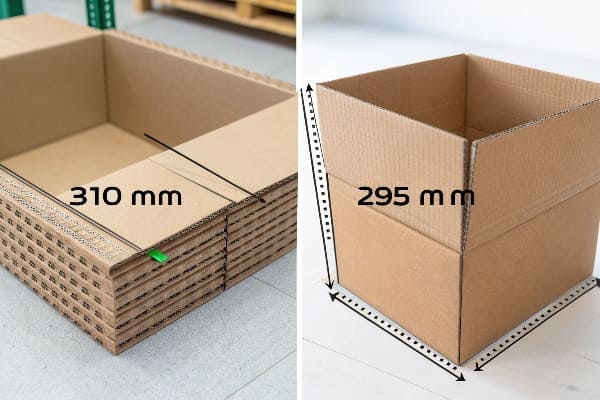

I see buyers confuse inner and outer size. I did it once with a countertop display. The shipper came 3 mm too tight. The tabs crushed.

Measure corrugated boxes by inside dimensions in the order length × width × height; confirm product fit, add clearance for inserts, and account for board thickness and pallet layout.

Steps, tolerances, and layout

I always measure inside size first. I place the product or the display flat and snug. I record length (the longer open side), width (the shorter open side), and height (from base to opening). I allow 3–6 mm clearance per side for assembly and air. I add more if I place foam, honeycomb pads, or corner posts. Then I convert to die-cut blanks. Board thickness adds to outside size, so I check pallet plans. I try to hit 600 × 400 mm or 24 × 20 in footprints that stack well in U.S. and EU systems. I also check carrier rules for girth and weight. For e-commerce, I watch dimensional weight5. I trim height to avoid price jumps. I make a sample and run a fit test. I do a drop test6 from 76 cm on corners and faces. I also run ECT checks to match stack time. This process saves money and prevents store returns. It also protects color boxes inside. Nothing hurts more than bright retail packs with crushed dents from a tight shipper.

Measuring checklist and quick table

| Step | What I do | Why it helps |

|---|---|---|

| 1 | Measure inside L × W × H | Ensures true product fit |

| 2 | Add clearance | Avoids crush during pack |

| 3 | Note board thickness | Converts to outside size |

| 4 | Palletize in CAD | Cuts freight and damage |

| 5 | Make sample and test | Finds problems before mass run |

What is meant by corrugated box?

People ask this when they face audits or when their teams must specify exact packaging. The answer should be short and firm.

"Corrugated box" means any container made from corrugated fiberboard, defined by at least one fluted medium glued to liners, engineered for strength, stacking, and protection in shipping or display.

Practical meaning for buying, testing, and sustainability

I write clear specs on every purchase order. I include flute type, wall type, ECT or BCT target, liner weights, print method, and coating. I add sustainability notes7, like recycled content and water-based inks. Retailers in North America and Europe push for these points. They want strong boxes, clean inks, and easy recycling. In Asia Pacific, speed and volume lead. Growth is fast due to e-commerce and retail expansion. I match that with digital print for short runs8 and fast turns. In my display business, I ship floor displays that carry heavy goods like crossbows and accessories. I use double-wall outers to stop tilt on pallets. I wrap with edge guards and test for vibration. I give clients 3D renders, then a working prototype. I allow free changes until fit and strength pass. This model costs me some time in front. It pays back with steady repeat orders. Clear meaning and clear tests remove disputes. That keeps launches on time.

Spec elements I always include

| Spec Field | Example | Note |

|---|---|---|

| Board | BC double-wall, 32/26 ECT | For heavy kits |

| Liners | 200 gsm kraft / 175 gsm kraft | Humidity and tear |

| CMYK water-based flexo | Safer, fast | |

| Coating | Aqueous matte | Retail look |

| Tests | ECT 44, drop, vibration | Verifies claims |

| Sustainability | 80% recycled content, FSC mix | Meets audits |

Conclusion

Corrugated boxes use flutes and liners to balance strength, cost, and print. I measure inside first, test early, and specify clearly. That simple process keeps launches on time.

Exploring the advantages of Kraft liners can help you choose the right materials for humidity resistance and durability. ↩

Understanding ECT testing is crucial for ensuring your packaging can withstand stacking and shipping stresses. ↩

Explore the advantages of E-flute for retail packaging, including its print quality and suitability for various products. ↩

Learn how using recycled liners can enhance sustainability in packaging while maintaining quality and performance. ↩

Understanding dimensional weight is crucial for optimizing shipping costs and ensuring efficient packaging. ↩

Exploring drop tests can help you learn how to ensure product safety during shipping and prevent damage. ↩

Explore this link to learn how to effectively incorporate sustainability into your purchasing process, enhancing your brand's eco-friendly image. ↩

Discover the advantages of digital printing for short runs, which can significantly improve efficiency and responsiveness in e-commerce. ↩