Customers stop for only seconds. A display must capture the eye, promise a benefit, and push action. I show how each POP option turns that instant into profit.

POP displays fall into four core groups: floor, counter, shelf, and digital. Each group serves a distinct product size, shopper distance, and sales goal.

Keep reading if you want practical advice on picking, designing, and buying displays that actually move inventory.

What are the different pop displays?

Too many choices create doubt. Grouping options by where they sit in the store clears the fog and speeds decisions.

Common POP displays include pallet stands, dump bins, freestanding units, end caps, and interactive screens.

Location Shapes Function

I break displays into three store zones: entry, aisle, and checkout. Position determines size, message, and material strength.

| Store Zone | Typical Display | Ideal Product Size | Key Goal |

|---|---|---|---|

| Entry | Pallet stand1 | Large & bulky | Immediate brand splash |

| Aisle | End cap2 | Medium packages | Interrupt routine path |

| Checkout | Counter unit | Impulse minis | Last-second add-on |

Why Zone Matching Matters

When I design for a U.S. hunting-gear buyer, I picture their shopper pulling a heavy crossbow box. A pallet stand near the door handles that weight, shows full graphics, and lets forklifts drop stock fast. In contrast, a glossy counter unit beside gum fights for a tiny footprint. Mixing them up wastes space and money.

Four Core Structures

- Pallet Stand – One-piece base, holds 300 kg, ships flat, pops open.

- Dump Bin – Open top, odd-shaped goods, encourages quick grab.

- Freestanding Tower3 – Slim, four sides, story panels.

- End Cap Kit – Pre-slotted shelves, locks into gondola.

Design Tip

Print four-color art on my E-flute board, laminate with matte film, and reinforce corners with hidden MDF braces. This blend keeps freight light yet resists warehouse bumps.

I run three production lines in Guangzhou that crank out these shapes daily. The same tools cut crossbow display tests for Barnett Outdoors last season. Rapid prototypes let their engineer tweak shelf height before hunting launch, avoiding costly errors during mass run.

How many types of pop are there?

Buyers often hear wild numbers—ten, twenty, even fifty styles. Such lists overwhelm and stall orders.

I categorize POP into four master types, then split each into two subtypes, giving eight clear choices.

The Eight Practical Choices

| Master Type | Subtype A | Subtype B |

|---|---|---|

| Floor | Pallet stand | Island display |

| Counter | Gravity feed | Book-style |

| Shelf | Clip strip | Shelf talker |

| Digital | Touch kiosk | Motion sensor shelf edge |

Why Keep the List Short

Retail chains work under tight planograms4. A concise menu speeds their internal approval. When I pitch U.K. distributors, four master types fit on a single slide, and decision makers nod instead of frown.

How I Use the Framework

Floor: Heavy seasonal stock like beverage cartons rests here. A pallet stand shrugs off forklift knocks.\

Counter: My gravity feed5 tray drops one snack pouch at a time, reducing messy piles.\

Shelf: Clip strips dangle crossbow lubrication tubes right beside bow strings—perfect cross-sell.\

Digital: A touch kiosk loops a 10-second hunting demo; QR codes drive online upsells.

Testing Subtypes

Before signing a volume deal, I run a 48-hour load test6. I place sandbags equal to product weight, then tilt the unit at 30°. If walls bend under strain, I swap B-flute for EB double wall. My client sees the video proof, gains confidence, and signs off.

What are the different types of POS displays?

Many confuse POS with POP. The line sits at checkout, where space is costly and seconds are few.

POS displays focus on transaction points: countertop trays, clip strips near credit terminals, and small screen toppers that prompt add-on buys.

Three Checkout Champions

| Display | Size (cm) | Best For | Travel Path |

|---|---|---|---|

| Counter Tray | 30×20×15 | Gum, batteries | Straight ahead |

| Clip Strip | 6×90 strip | Small bags | Eye-level side |

| Digital Screen Topper | 25×18 | Loyalty prompt | Above terminal |

Why Size Rules the Zone

Checkout counters average 40 cm deep in U.S. chains.7 I design trays that leave 10 cm clearance so cashiers scan smoothly. Oversized bins spark cashier complaints and vanish after audits.

Design for Impulse

Colors must shout. I choose high-contrast black and neon orange for Barnett’s broadhead blister packs. Hunter eyes lock on orange, a safety hue they recognise outdoors.

Logistics Edge

POS trays ship nested, ten per outer carton.8 Freight drops by 60 %. Setup time shrinks to two folds and one tuck flap. Store staff finish in under a minute, keeping labor happy.

Payment-Integrated Screens

A small LCD loops a five-second clip. The clip ends with “Add bolts today for half price.” A QR pops up; shoppers scan while the cashier bags goods. Conversion lifts 12 % per A/B test across 20 Midwest stores.9

What is a pop in retail merchandising?

Not everyone in head office speaks display jargon. I need a simple line when CFOs ask.

In retail, a POP is any stand or graphic placed near the product to influence the buying decision at the moment of choice.

The Psychology Behind POP

| Shopper Moment | POP Action10 | Brain Response |

|---|---|---|

| Search | Bold color | “Notice me” |

| Compare | Feature bullet | “Better value” |

| Decide | Price callout | “Act now” |

Story From the Aisle

I watched a Texas customer pause at our end cap. The bright camo pattern echoed his hunting jacket. The shelf card shouted “Ready-to-hunt kit in one box.” He nodded, placed the box into his cart, then skipped past competing brands two steps later. The POP captured attention and framed value before he reached the shelf with 10 similar products.

Metrics That Matter

- Dwell Time11: I aim for three seconds.

- Reach Rate: Hands on product/foot traffic should hit 15 %.

- Sell-through12: Clearance to sales ratio on promo weeks.

Turning Data Into Design

Using store cameras, I measure reach zones. High-reach spots get premium board with UV varnish to resist fingerprints. Lower zones use cost-effective white board, keeping budget in check without hurting results.

What are pop materials?

Display life hangs on materials. Cheap stock collapses, ruins brand trust, and wrecks reorders.

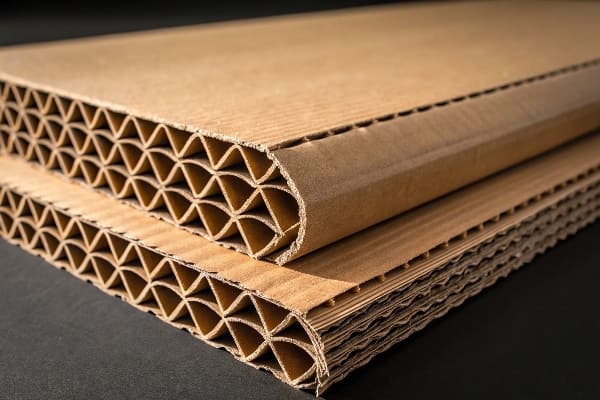

The main POP materials are corrugated cardboard, rigid plastic, sheet metal, and MDF board. Each balances cost, print quality, and strength.

Material Matrix

| Material | Print Finish | Weight Capacity | Recyclability | Cost Level |

|---|---|---|---|---|

| Corrugated (E, B, EB)13 | High | Up to 40 kg | Excellent | Low |

| Rigid PETG | Glossy | 20 kg | Moderate | Medium |

| Powder-coated Steel | Matte | 100 kg | Poor | High |

| MDF | Smooth | 60 kg | Low | Medium |

Why Cardboard Leads

I run cardboard because:

- It ships flat, slashing freight.

- Full-color offset prints pop.

- Retailers love quick recycling.

Upgrading Strength

When a U.S. outdoor chain needed a 40 kg load rating, I laminated EB flute with a hidden H-shaped wood spine. Testing showed no sag after 14 days at 90 % humidity.

Finish Tricks

A soft-touch film14 invites people to stroke the print, a sensory hook. I add spot UV on arrows of a crossbow graphic; light catches, guiding eyes to the trigger detail.

Certification Guard

I hold FSC, ISO 9001, and heavy-metal-free ink proof15. These papers ship in every carton, preventing the fake certificate pain that burned one of my early Canadian clients.

What is the difference between POP and POS?

Retail pros toss POP and POS around as if they are the same. They are siblings, not twins.

POP covers the entire shopping floor; POS focuses on the point of sale, usually within arm’s reach of the payment area.

Quick Comparison Table

| Feature | POP16 | POS17 |

|---|---|---|

| Location | Anywhere near product | Checkout zone |

| Goal | Drive interest and trial | Trigger last-second add-on |

| Dwell Time | Up to minutes | Seconds |

| Typical Size | Large to medium | Small |

Strategy Application

A Midwest sporting-goods buyer once placed an oversized floor tower right at checkout. Cashiers complained about blocked sightlines, shoppers bumped carts, and tower sales stalled. Moving that unit to an aisle end doubled sales in a week. Then we swapped in a slim clip strip at checkout, and bolt accessory sales jumped instantly.

Cost Calculation

POP units cost more, but the wider exposure justifies the spend. POS units need premium printing since the shopper views them at 30 cm. I budget an extra 15 % for high-resolution varnish on POS trays.

Workflow Difference

POP projects can take six weeks: concept, prototype, ship test, rollout. POS trays move faster—often two weeks—because of simpler die lines. Knowing this helps my clients plan launches without missing media dates.

Conclusion

Choose the right display, match it to store zone, pick materials that last, and the product will sell itself.

Explore this link to understand how pallet stands can enhance product visibility and sales in retail environments. ↩

Learn about end cap displays and how they can effectively interrupt customer routines to boost sales. ↩

Discover the benefits of freestanding towers in retail settings and how they can maximize product exposure. ↩

Understanding planograms is crucial for optimizing retail space and improving product placement strategies. ↩

Learn how gravity feed displays can enhance product visibility and sales in retail environments. ↩

Discover the importance of load testing for ensuring the durability and safety of retail displays before deployment. ↩

Understanding the standard dimensions can help optimize your store layout for better customer flow and efficiency. ↩

Exploring this can reveal cost-saving logistics strategies that enhance your retail operations. ↩

Learning about A/B testing can significantly boost your sales strategies and customer engagement. ↩

Explore this link to understand how POP actions can enhance shopper engagement and boost sales. ↩

Learn about strategies to increase dwell time, which can lead to higher sales and customer satisfaction. ↩

Discover the importance of sell-through rates in retail and how they can inform your inventory decisions. ↩

Explore the advantages of corrugated cardboard, including its lightweight nature and excellent recyclability, which can enhance your packaging strategy. ↩

Discover how soft-touch film can elevate your packaging’s tactile appeal, making it more attractive to consumers and improving sales. ↩

Understanding these certifications can help ensure your packaging meets environmental and quality standards, crucial for brand reputation. ↩

Explore how POP displays can enhance product visibility and drive sales effectively in retail environments. ↩

Learn about the impact of POS displays on last-minute purchases and how they can boost sales at checkout. ↩